A heat treatment method for high-temperature carburizing stainless steel and low-pressure vacuum carburizing

A heat treatment method and high temperature carburizing technology, applied in solid diffusion coating, coating, metal material coating process, etc., can solve the problem of carbide size, poor distribution uniformity, complex composition system and heat treatment process, hardness The performance requires high service temperature to achieve the effect of accurately controlling the depth of the seepage layer, solving environmental pollution and internal oxidation, and achieving good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

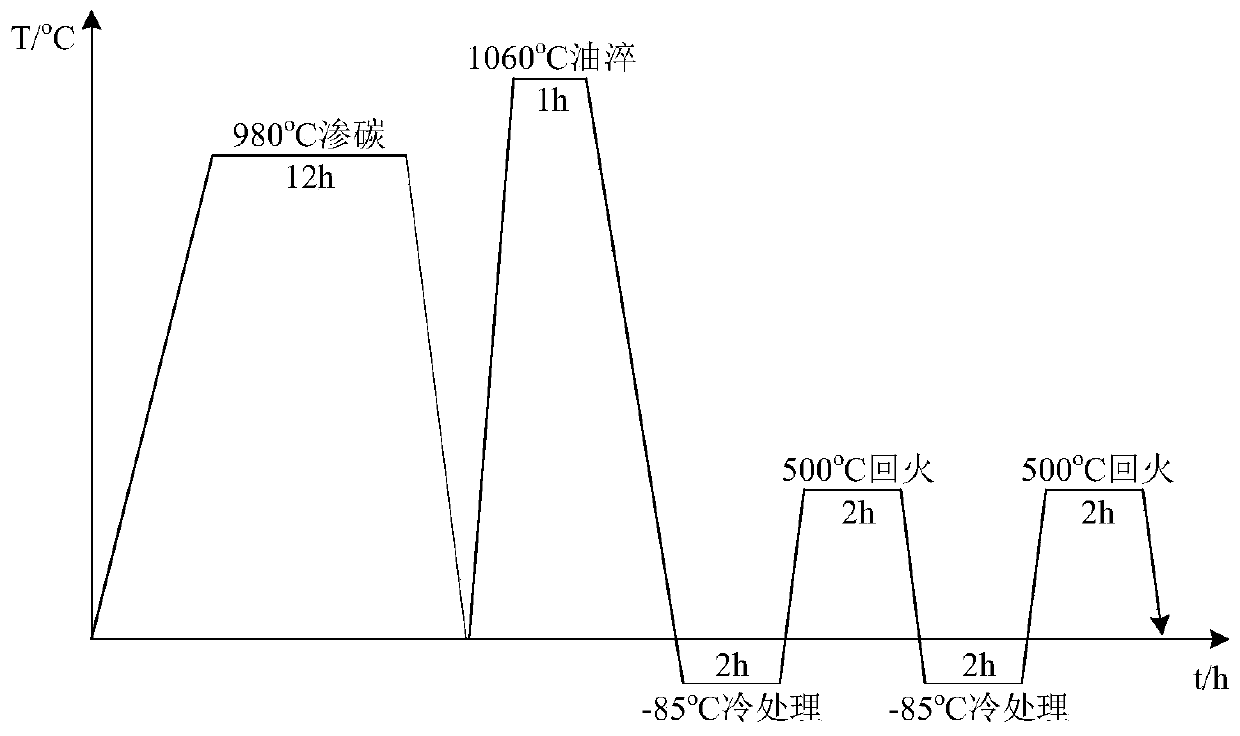

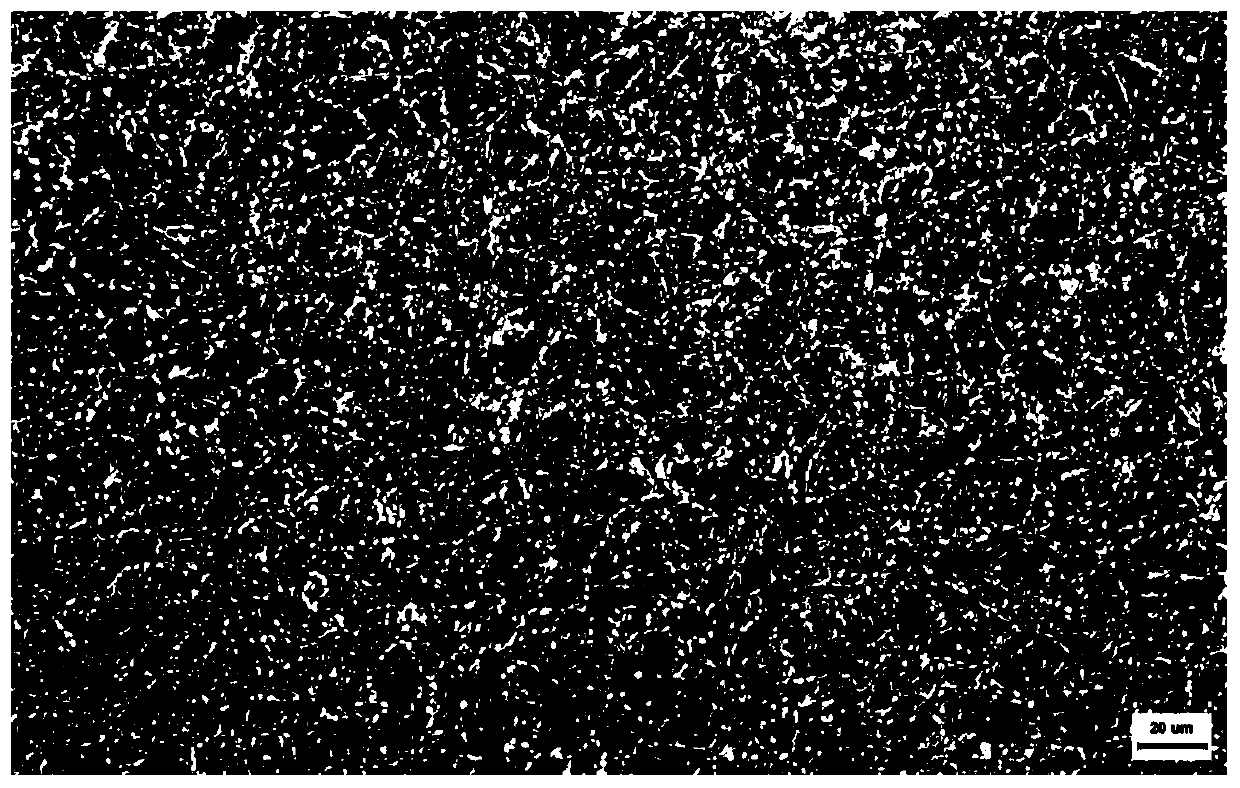

[0042] Embodiment 1 is carburized in a double-chamber low-pressure vacuum carburizing furnace, and its heat treatment process steps are as follows: figure 1 As shown, the preset infiltration layer depth is 0.8mm. First, prepare a high-temperature carburized stainless steel sample, the sample composition is C 0.14%, Si 0.2%, Mn0.3%, Cr 13.8%, Co 12.8%, Ni 1.8%, W0.5%, Mo 4.7%, V 0.6%, the balance is Fe and unavoidable impurities. Secondly, a) Clean the surface of the sample to remove oil stains, dry it and put it into the furnace and vacuumize it with an absolute pressure of 20Pa. b) Put the sample into a low-pressure vacuum carburizing furnace and heat it. The heating process is a three-stage heating process. The heating rate is 10°C / min, and it is kept at 650°C, 850°C and 980°C for 1 hour respectively. The carburizing temperature is 980°C. c) Fill the furnace with high-purity acetylene gas, adjust to a stable pressure of 800Pa, and enter the strong infiltration stage. At t...

Embodiment 2

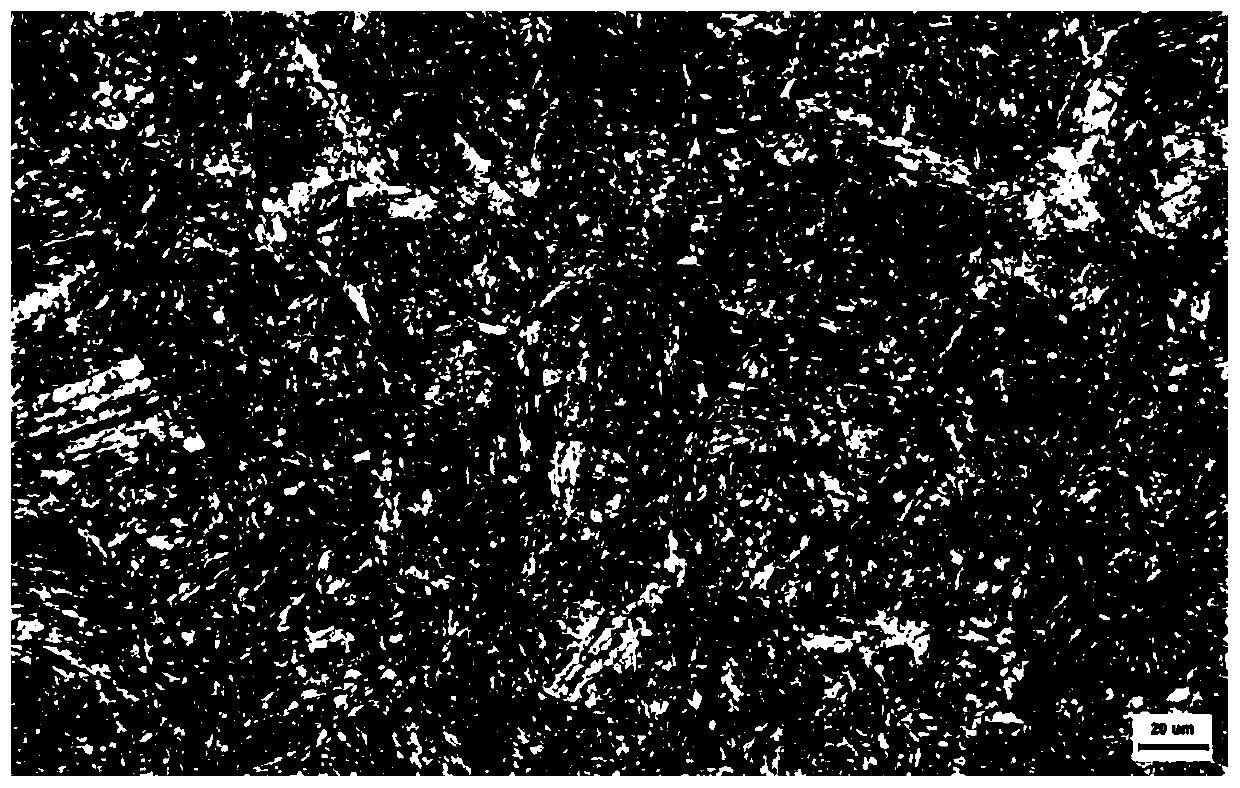

[0049] Carburizing in a double-chamber low-pressure vacuum carburizing furnace, the heat treatment process steps are as follows Figure 5 As shown, the preset infiltration layer depth is 1.0mm. Prepare high-temperature carburized stainless steel material samples, the sample composition is C0.14%, Si 0.25%, Mn 0.4%, Cr13.8%, Co 13%, Ni 1.8%, Mo 4.6%, V0.6%, Nb 0.03 %. Clean the surface of the sample to remove oily dirt, dry it and put it into the furnace and vacuumize it. Put the sample into a low-pressure vacuum carburizing furnace for heating. The heating process is a three-stage heating process. The heating rate is 10°C / min, and the heat preservation is at 650°C, 850°C and 960°C for 1 hour respectively, and the carburizing temperature is 960°C. . Fill the furnace with high-purity acetylene gas, adjust to a stable pressure of 800Pa, and enter the strong infiltration stage. At this time, the decomposition, adsorption and infiltration of acetylene in the furnace will increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com