Micro-etching solution capable of preventing circular hole from turning white

A technology of micro-etching solution and hole ring, which is applied in the field of printed circuit board production, can solve the problems of copper lattice change, white hole ring, etc., and achieve the effects of promoting corrosion, avoiding air, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

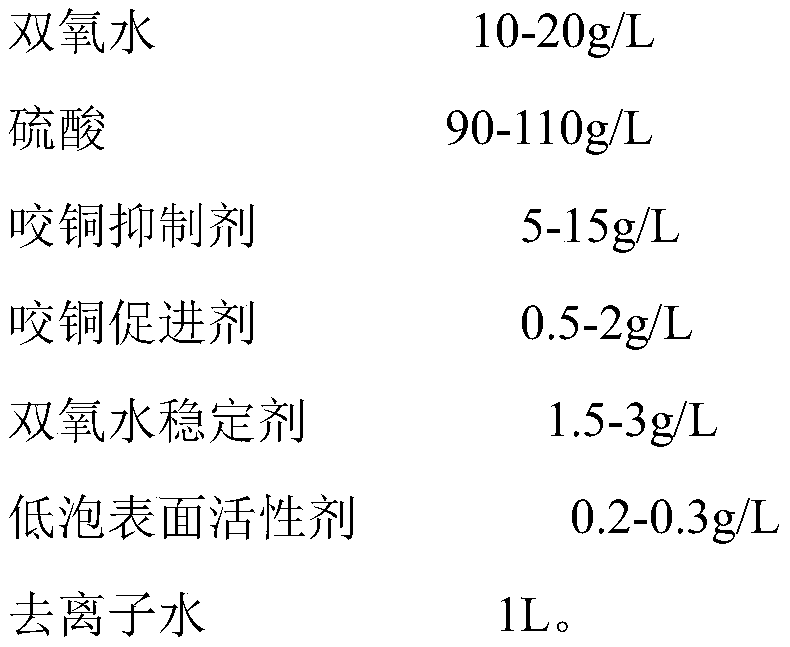

[0034] A microetching solution that can prevent the whitening of the hole circle, wherein the mass concentration of each component of the microetching solution is as follows:

[0035]

[0036] Wherein the copper biting inhibitor is citric acid;

[0037] The copper-biting accelerator is cycloethylamine;

[0038] The hydrogen peroxide stabilizer is methanesulfonic acid;

[0039] The low-foaming surfactant is fatty acid methyl ester polyoxyethylene ether.

[0040] A kind of microetching solution that can prevent hole ring from turning white, its proportioning process comprises the following steps:

[0041] (1) Add 500 deionized water in the micro-etching tank;

[0042] (2) Add the copper-biting accelerator into the micro-etching tank in step (1) and stir for 7 minutes;

[0043] (3) adding mass concentration to the microetching tank in step (2) is 50% sulfuric acid;

[0044] (4) Add the copper-biting inhibitor into the micro-etching tank in step (3) and stir for 8 minutes;...

Embodiment 2

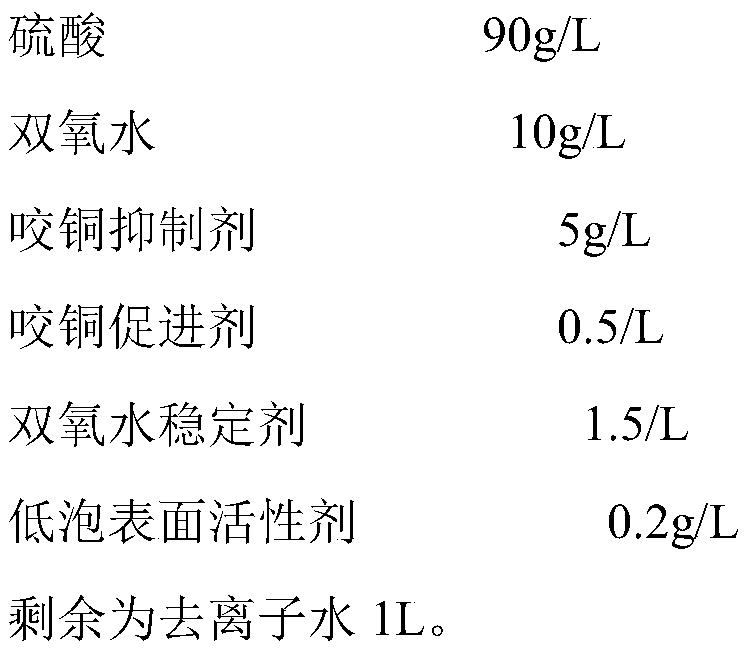

[0048] A microetching solution that can prevent the whitening of the hole ring, wherein the mass concentration of each component of the microetching solution is as follows:

[0049]

[0050] Wherein the copper biting inhibitor is methanesulfonic acid;

[0051] The copper-biting accelerator is n-butanol;

[0052] The hydrogen peroxide stabilizer is phenolsulfonic acid;

[0053] The low-foaming surfactant is fatty acid methyl ester polyoxyethylene ether.

[0054] A kind of microetching solution that can prevent hole ring from turning white, its proportioning process comprises the following steps:

[0055] (1) Add 600ml of deionized water into the micro-etching tank;

[0056] (2) Add the copper-biting accelerator into the micro-etching tank in step (1) and stir for 6 minutes;

[0057] (3) adding mass concentration to the microetching tank in step (2) is 50% sulfuric acid;

[0058] (4) Add the copper-biting inhibitor into the micro-etching tank in step (3) and stir for 7 m...

Embodiment 3

[0062] A kind of microetching solution that can prevent hole ring from turning white, comprising the following parts by weight:

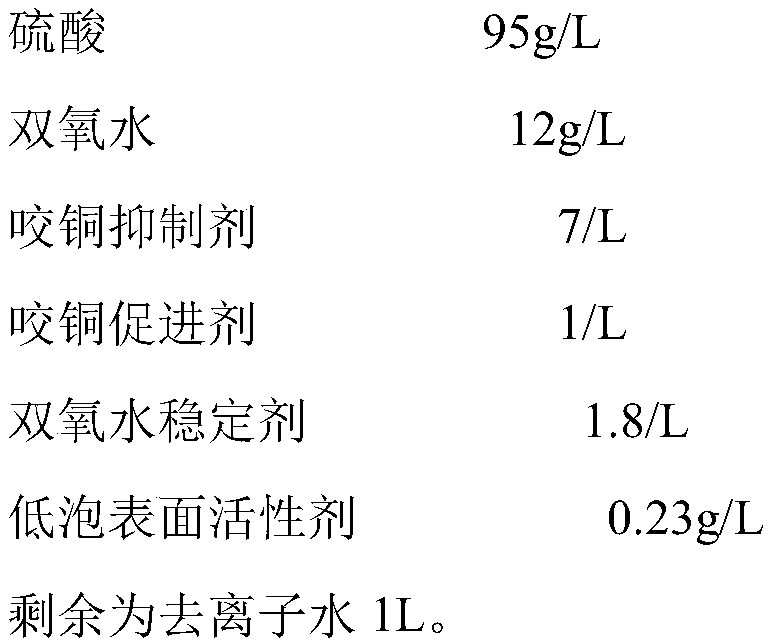

[0063]Wherein the mass concentration of each component of the microetching solution is as follows:

[0064]

[0065]

[0066] Wherein the copper biting inhibitor is tartaric acid;

[0067] The copper-biting accelerator is n-octylamine;

[0068] The hydrogen peroxide stabilizer is p-toluenesulfonic acid;

[0069] The low foaming surfactant is isooctyl alcohol.

[0070] A kind of microetching solution that can prevent hole ring from turning white, its proportioning process comprises the following steps:

[0071] (1) Add 700ml of deionized water into the micro-etching tank;

[0072] (2) Add the copper-biting accelerator into the micro-etching tank in step (1) and stir for 5 minutes;

[0073] (3) adding mass concentration to the microetching tank in step (2) is 50% sulfuric acid;

[0074] (4) Add the copper-biting inhibitor into the micro-et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com