A Calculation Method for Thermal Neutron Scattering Effect of Silicon Carbide Coated Molten Salt Reactor

A silicon carbide coating and neutron scattering technology, which is applied in computational theoretical chemistry, instrumentation, informatics, etc., can solve the problems of reducing the penetration of flowing molten salt, avoiding loss of precision, reducing the possibility of damage, and uniformity The precise effect of parameterization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

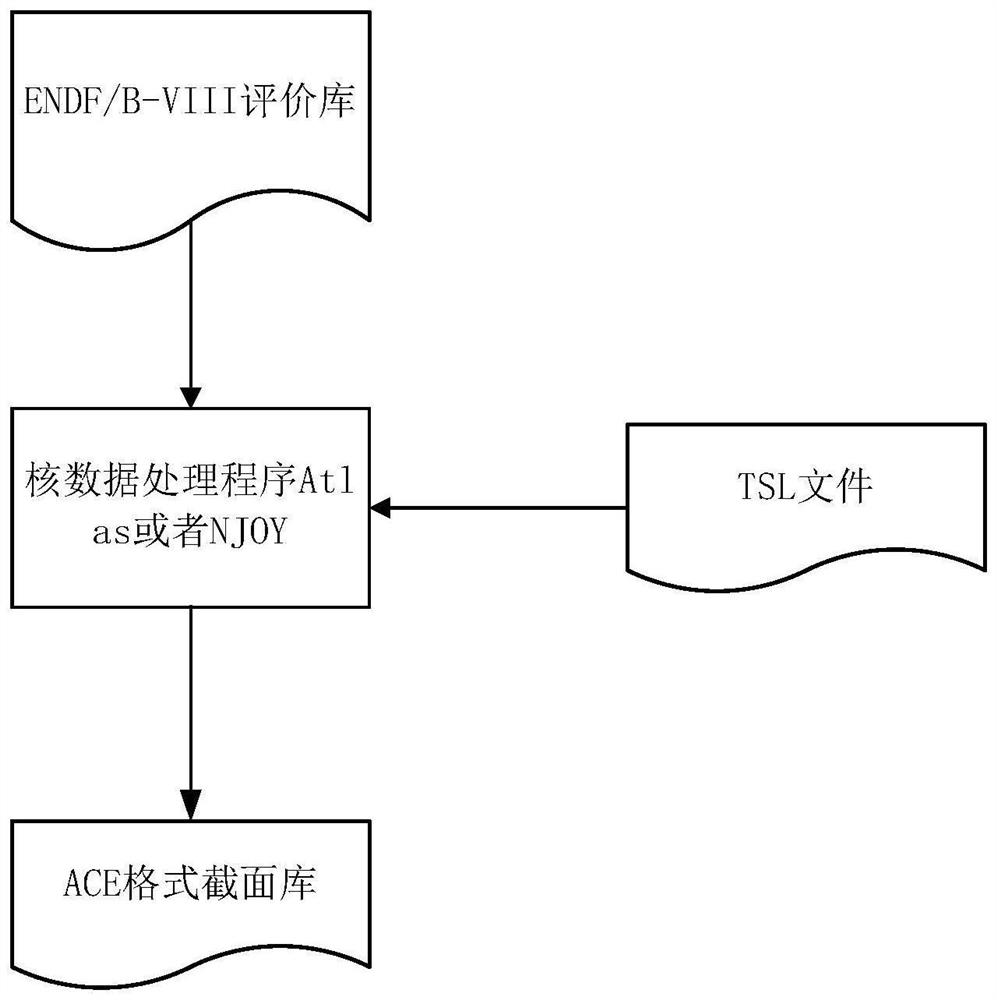

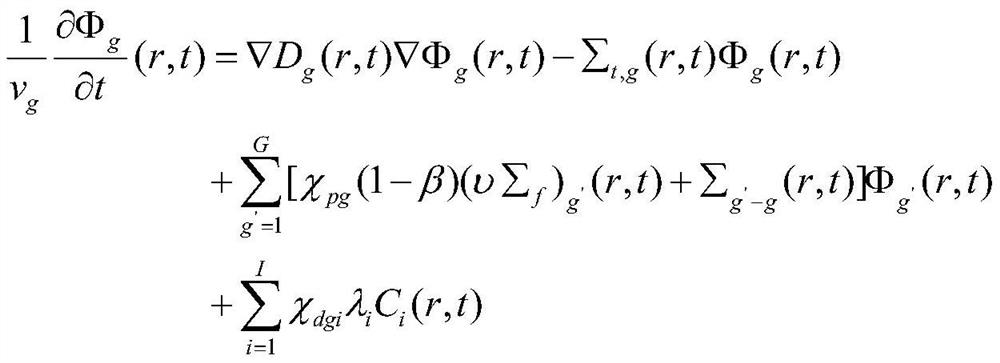

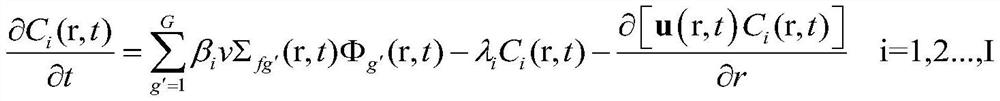

[0025] This embodiment provides a calculation method for the thermal neutron scattering effect of a silicon carbide coated molten salt reactor. Whether it is a solid fuel molten salt reactor or a liquid fuel molten salt reactor, flowing liquid molten salt is used as the coolant. When the salt flows over the graphite surface inside the molten salt pile, the molten salt will permeate into the graphite, which may form a hot spot inside the graphite, which will increase the temperature of the graphite unacceptably, and may even cause the graphite to be damaged. The silicon carbide material is effective in reducing the penetration of molten salts, because there are already fuel element designs that replace the graphite matrix with silicon carbide. However, considering that the neutron economy of silicon carbide is not as good as that of graphite, if silicon carbide replaces the graphite matrix, a large amount of neutrons may be absorbed unhelpfully, so this embodiment proposes to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com