Fabrication process of solid-state aluminum electrolytic capacitor with high capacity leading-out rate

A technology of aluminum electrolytic capacitor and preparation process, applied in solid electrolytic capacitors and other directions, can solve the problems of low capacity extraction rate, large leakage current, slow moving speed of polymer electrolyte, etc., and achieve the effect of high capacity extraction rate and low leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

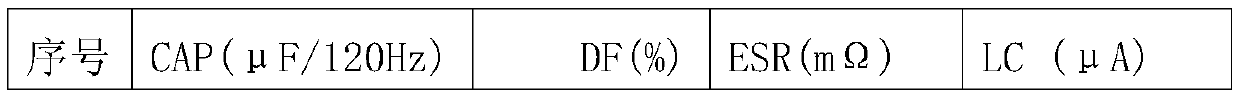

Embodiment 1

[0026] A preparation process of a solid aluminum electrolytic capacitor with high capacity extraction rate, the specific steps are as follows:

[0027] Step 1, cutting the positive foil, negative foil and release paper to the required width;

[0028] Step 2, use a stitching machine to nail the positive guide pin and the negative guide pin to the positive foil and the negative foil respectively, and wind the stapled foil and release paper into a prime;

[0029] Step 3. Weld the element on the stainless steel iron bar, and perform short circuit treatment (short circuit: after the element is nailed and rolled, the element is instantly connected to a large DC voltage, generally with a DC voltage that is twice the withstand voltage of the foil , if there is a burr that has a greater impact, the element will spark, thus picking out the element that is easy to short-circuit in the later stage);

[0030] Step 4: Carrying out chemical conversion treatment and drying the element in ste...

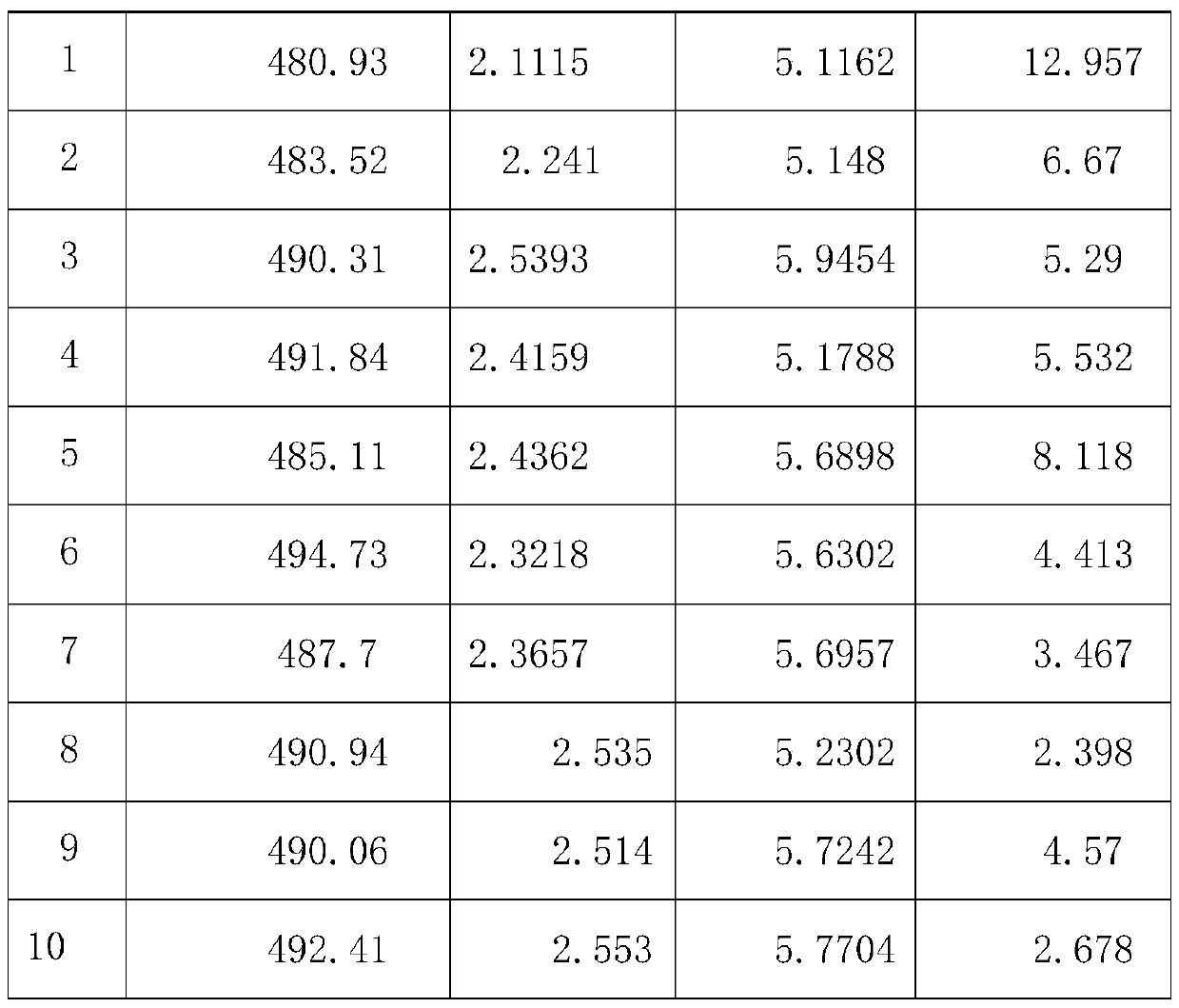

Embodiment 2

[0047] A preparation process of a solid aluminum electrolytic capacitor with high capacity extraction rate, the specific steps are as follows:

[0048] Step 1, cutting the positive foil, negative foil and release paper to the required width;

[0049] Step 2, use a stitching machine to nail the positive guide pin and the negative guide pin to the positive foil and the negative foil respectively, and wind the stapled foil and release paper into a prime;

[0050] Step 3: Weld the element on the stainless steel iron bar, and perform short-circuit treatment (short-circuit: after the element is nailed and rolled, the element is instantly connected to a larger DC voltage, generally using a DC voltage that is three times the withstand voltage of the foil , if there is a burr that has a greater impact, the element will spark, thus picking out the element that is easy to short-circuit in the later stage);

[0051] Step 4: Carrying out chemical conversion treatment and drying the elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com