Flexible electrode material with adjustable pore size and its preparation method and application

A flexible electrode and pore size technology, which is applied in the preparation/purification of carbon, electrode carrier/current collector, nanotechnology for materials and surface science, etc., can solve the problem that the pore size and size of flexible electrode materials cannot be effectively controlled, battery The overall performance is greatly affected, and the active material cannot be loaded, etc., to achieve the effect of excellent elastic performance, excellent electrochemical performance and low resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

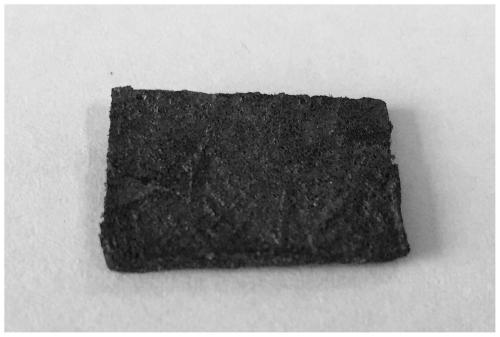

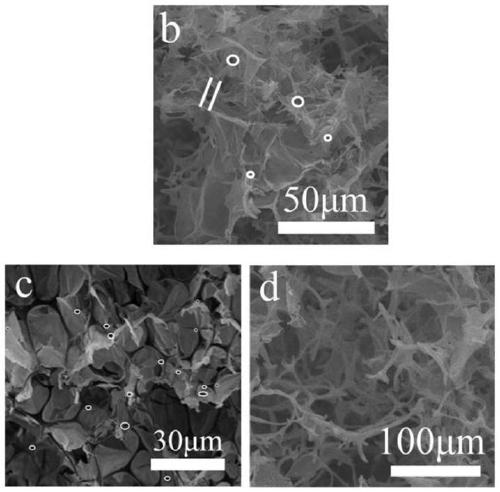

[0035] A flexible electrode material with adjustable pore size, the flexible electrode material is a double network carbon structure, the double network carbon structure includes a primary porous network carbon skeleton, and the pores of the primary porous network carbon skeleton are also filled with a secondary porous network carbon skeleton . Among them, the primary porous network carbon skeleton is formed by carbonization of melamine sponge, and the secondary porous network carbon skeleton is formed by carbonization of nanocellulose filled in the pores of melamine sponge. The pore size of the flexible electrode material in this embodiment is about 500-1000 nm.

[0036] The preparation method of the above-mentioned flexible electrode material with adjustable aperture comprises the following steps:

[0037] (1) Take the nanocellulose sol, prepare the nanocellulose solution with a mass fraction of 0.1% by ultrapure water, and then ultrasonically crush it in an ultrasonic pulv...

Embodiment 2

[0044] A flexible electrode material with adjustable pore size, the flexible electrode material is a double network carbon structure, the double network carbon structure includes a primary porous network carbon skeleton, and the pores of the primary porous network carbon skeleton are also filled with a secondary porous network carbon skeleton . Among them, the primary porous network carbon skeleton is formed by carbonization of melamine sponge, and the secondary porous network carbon skeleton is formed by carbonization of nanocellulose filled in the pores of melamine sponge. The pore size of the flexible electrode material in this embodiment is about 20-300 nm.

[0045] The preparation method of the above-mentioned flexible electrode material with adjustable aperture comprises the following steps:

[0046] (1) Take the nanocellulose sol, prepare the nanocellulose solution with a mass fraction of 0.5% by ultrapure water, and then ultrasonically crush it in an ultrasonic pulver...

Embodiment 3

[0052] A flexible electrode material with adjustable pore size, the flexible electrode material is a double network carbon structure, the double network carbon structure includes a primary porous network carbon skeleton, and the pores of the primary porous network carbon skeleton are also filled with a secondary porous network carbon skeleton . Among them, the primary porous network carbon skeleton is formed by carbonization of melamine sponge, and the secondary porous network carbon skeleton is formed by carbonization of nanocellulose filled in the pores of melamine sponge. The pore size of the flexible electrode material in this embodiment is about 20-200 nm.

[0053] The preparation method of the above-mentioned flexible electrode material with adjustable aperture comprises the following steps:

[0054] (1) Take the nanocellulose sol, prepare the nanocellulose solution with a mass fraction of 0.8% by ultrapure water, and then ultrasonically crush it in an ultrasonic pulver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com