Exhaust gas purification catalyst

一种废气净化、催化剂的技术,应用在物理/化学过程催化剂、催化剂活化/制备、金属/金属氧化物/金属氢氧化物催化剂等方向,能够解决没有研究压力损失、废气净化性能下降、废气净化性能降低等问题,达到优化废气净化性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] Hereinafter, the present invention will be described in more detail using examples. However, the technical scope of the present invention is not limited by these examples.

[0071] 1. OSC material

[0072] As the OSC material, ceria-zirconia (CeO 2 -ZrO 2 ) composite oxides.

[0073] Preparation of Ceria-Zirconia Composite Oxide (Pyrochlore ZC) with Pyrochlore Structure

[0074] will be CeO 2 49.1 g of a 28% by weight aqueous cerium nitrate solution in terms of ZrO 2 After dissolving 54.7 g of an aqueous zirconyl nitrate solution of 18% by weight in conversion and a commercially available surfactant in 90 mL of ion-exchanged water, 1.2 times the equivalent of NH was added to the anion. 3 In 25% by weight of ammonia water, a coprecipitate was generated, and the obtained coprecipitate was filtered and washed. Next, the obtained coprecipitate was dried at 110° C., and then fired at 500° C. in the air for 5 hours to obtain a solid solution of cerium and zirconium. T...

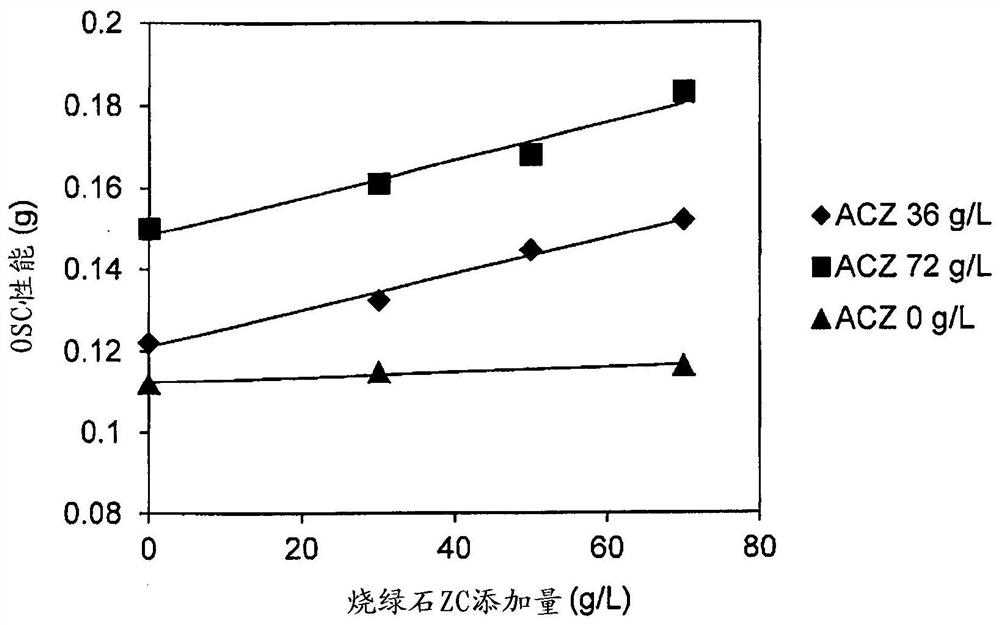

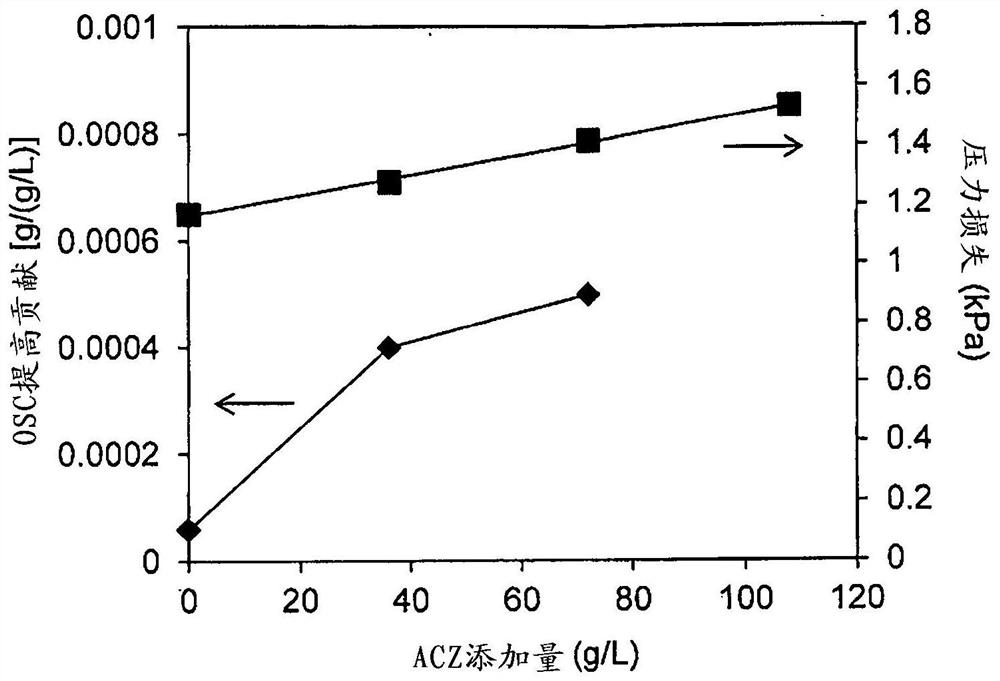

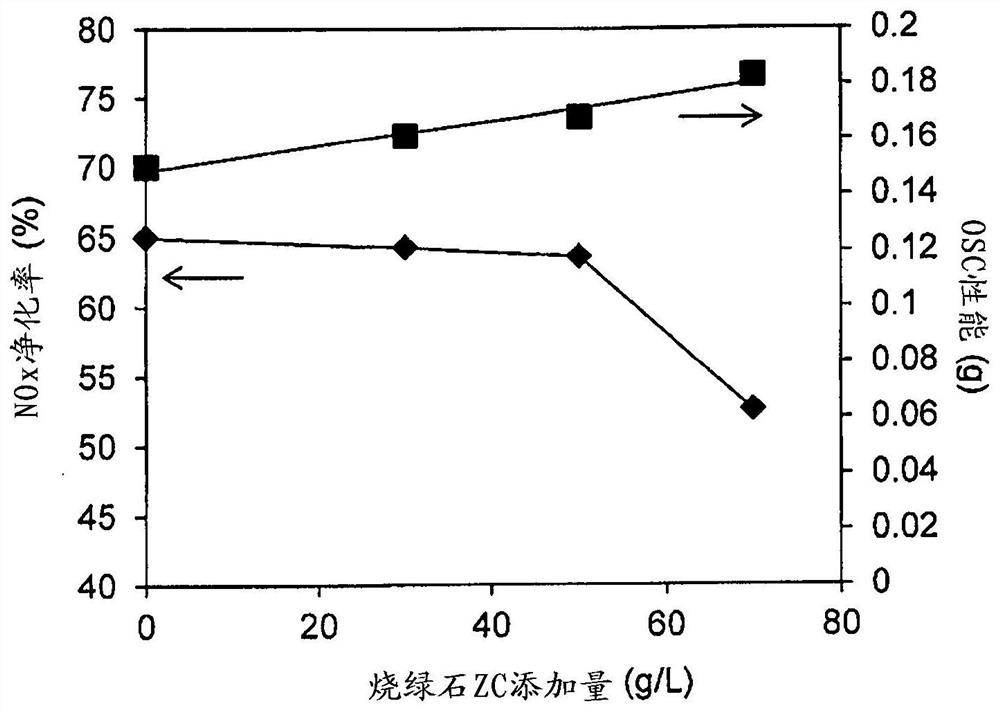

Embodiment 1、2 and comparative example 5

[0092] In Examples 1, 2, and Comparative Example 5, pyrochlore ZC was added to the slurry 2 for forming the upper layer of the catalyst coating so that the capacity relative to the substrate was 30 g / L, 50 g / L, and 70 g / L, respectively. Each catalyst was obtained in the same manner as in Comparative Example 4 except for the amount of L.

Embodiment 3、4 and comparative example 7

[0094] In Examples 3, 4, and Comparative Example 7, pyrochlore ZC was added to the slurry 2 for forming the catalyst coating layer of the upper layer, so that the capacity relative to the base material became 30 g / L, 50 g / L, and 70 g / L, respectively. Each catalyst was obtained in the same manner as in Comparative Example 6 except for the amount of L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com