Vulcanized foam rubber and preparation method thereof

A technology of foamed rubber and vulcanizing agent, applied in the field of rubber, which can solve problems such as difficult control and complicated process, and achieve the effect of moderate strength, uniform cell structure and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The invention provides a kind of preparation method of vulcanized foam rubber, and this preparation method comprises:

[0020] (1) Carrying out one-stage mixing of component A containing rubber matrix and vulcanization activator to obtain one-stage rubber compound;

[0021] (2) Carrying out two-stage mixing of the one-stage rubber compound with component B containing a vulcanizing agent, a vulcanization accelerator and a foaming agent, to obtain a two-stage rubber compound;

[0022] (3) Vulcanize the second-stage rubber compound;

[0023] Wherein, the vulcanization includes three stages carried out in sequence: the conditions of the first stage vulcanization include: the vulcanization temperature is 100-170°C, the vulcanization pressure is 10-20MPa, and the vulcanization time is 2-20min; the second stage vulcanization Keep the pressure of the first stage of vulcanization constant, the temperature of the second stage of vulcanization is higher than the temperature of th...

Embodiment approach

[0055] According to a preferred embodiment of the present invention, the preparation method of described vulcanized rubber comprises:

[0056] (1) Set the initial temperature of the internal mixer to 60-80°C and the rotational speed to 50-80 rpm, put the rubber matrix into the internal mixer for mastication for 0.5-1min, and then put in reinforcing agent, anti-aging agent, plasticizer Mixing agent and vulcanization activator for 3-5 minutes, deglue and stop for cooling for more than 4 hours to obtain a masterbatch;

[0057] (2) Set the initial temperature of the internal mixer to 50-60°C, and the speed to 50-80 rpm, and add a section of masterbatch, vulcanizing agent, vulcanization accelerator, foaming agent and foaming aid in order for mixing Mixing, the mixing time is 3-4min, when the second-stage mixing is completed, the glue can be removed;

[0058] (3) Pass the rubber compound obtained in step (2) once on the open mill with a roll distance of 0.2-0.8mm and a roll tempera...

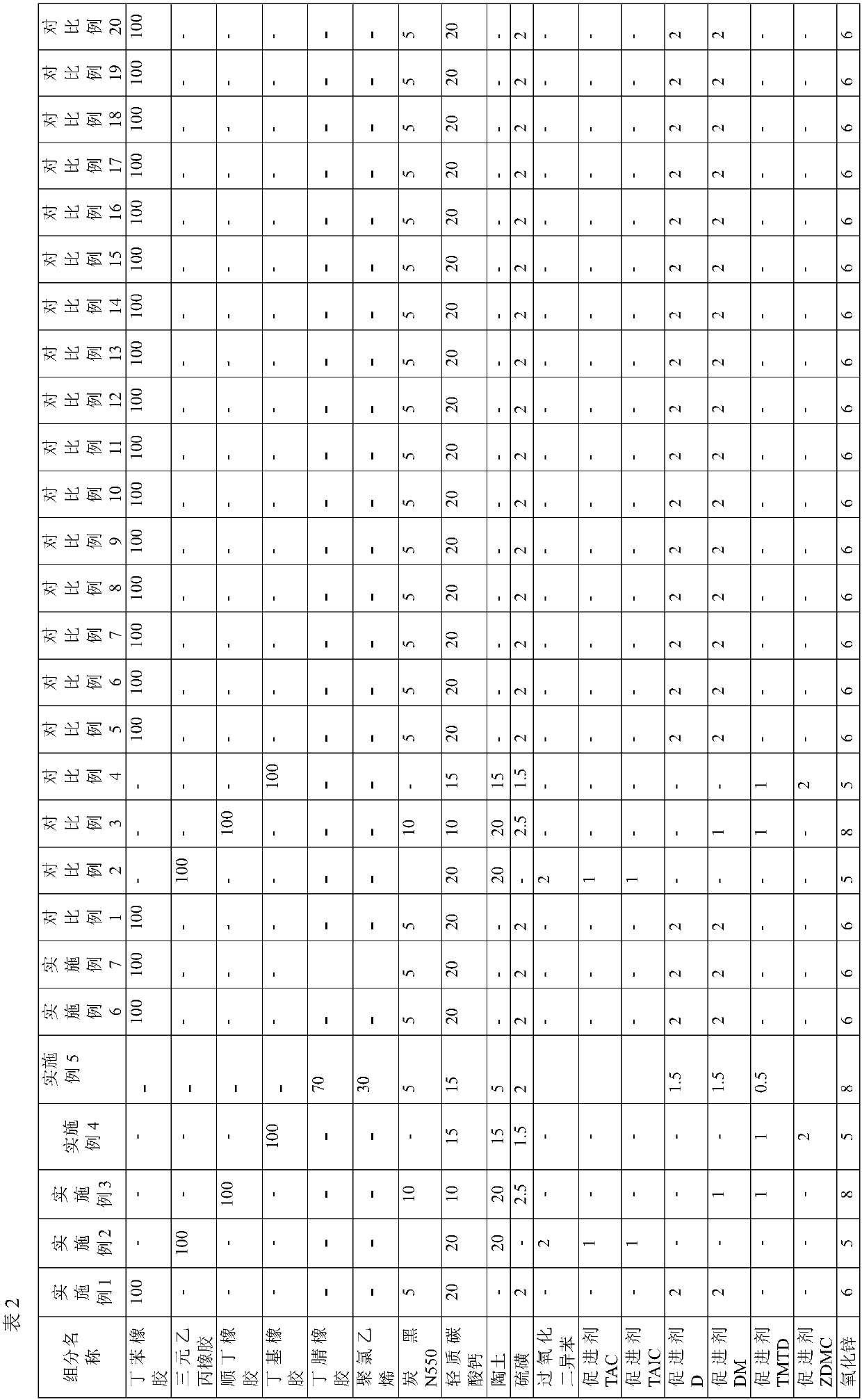

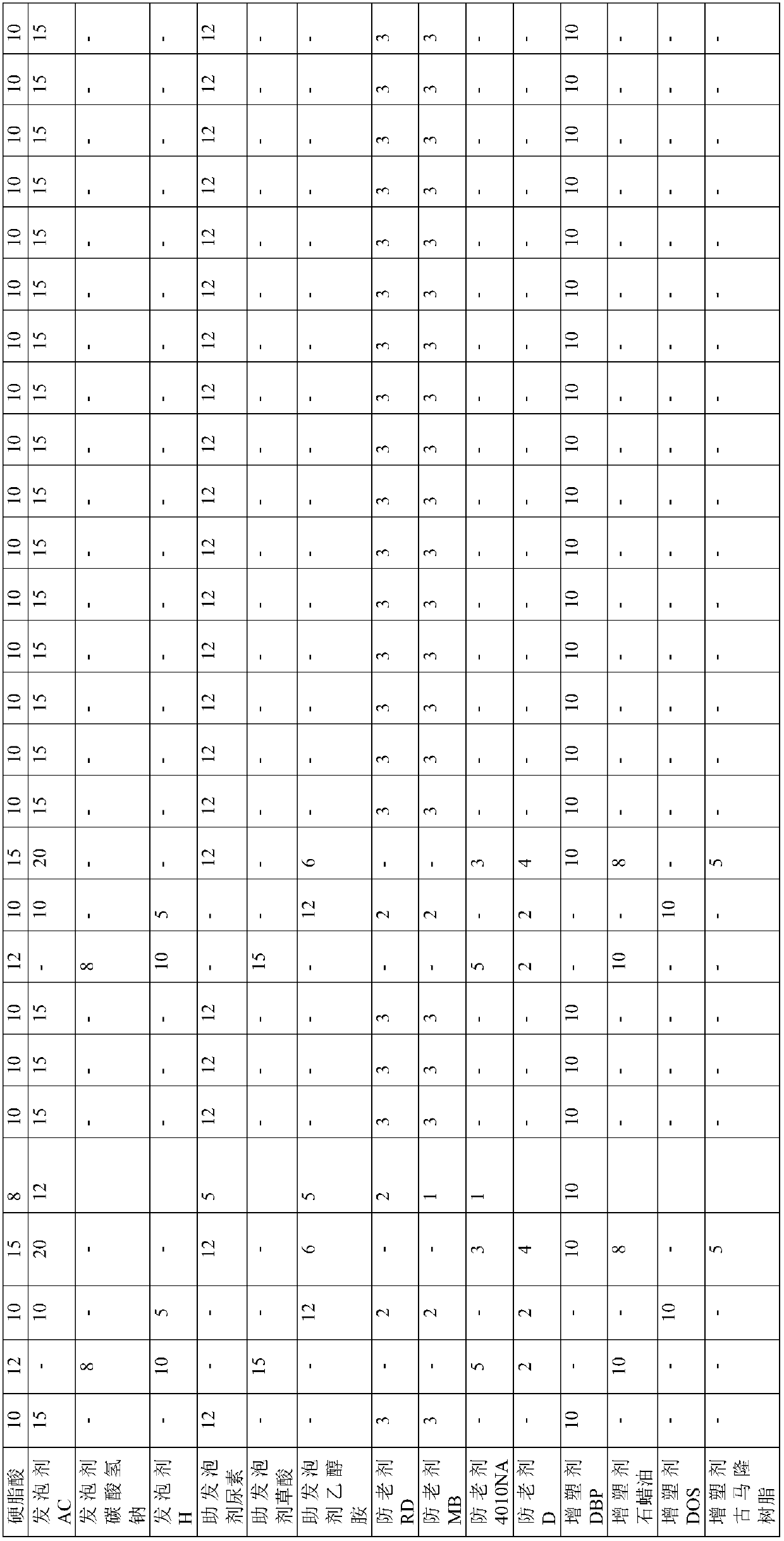

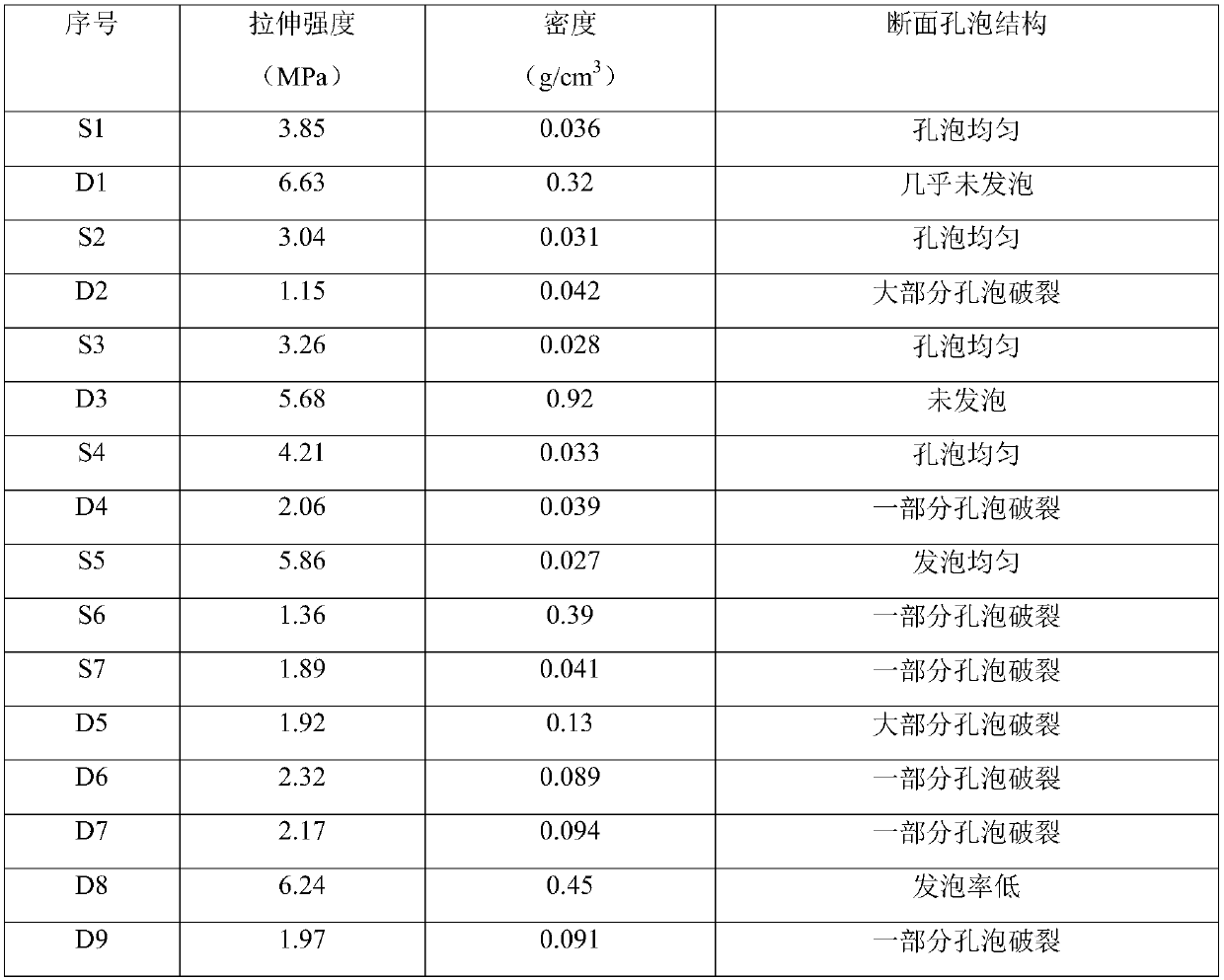

Embodiment 1

[0082] The formulations of the components involved in the method of this embodiment are shown in Table 2 (wherein the numerical values are parts by weight relative to 100 parts by weight of the rubber matrix). The preparation method of the vulcanized foam rubber S1 of the present embodiment is specifically as follows:

[0083] The first stage of mixing:

[0084] Set the initial temperature of the internal mixer to 70°C, and the rotor speed to 70r / min, add styrene-butadiene rubber to the internal mixer for mastication for 0.5min, and then put in carbon black, light calcium carbonate, stearic acid, zinc oxide, anti-aging agent and The plasticizer continued to mix for 3 minutes, deglue, and parked for 4 hours to obtain a section of masterbatch.

[0085] The second stage of mixing:

[0086] Set the initial temperature of the internal mixer to 50°C, and the rotor speed to 60r / min. Add a section of masterbatch, sulfur, accelerator, foaming agent and foaming aid into the internal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com