High-temperature-stable slow-digestion starch and preparation method thereof

A technology for high temperature stabilization and digestion of starch, applied in the field of high temperature stable slow digestion starch, can solve the problems of high temperature processing and instability of slowly digested starch, and achieve the solution of high temperature processing instability, high freeze-thaw stability, and recovery from long-term aging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Preparation method of high temperature stable slowly digestible starch

[0065] The preparation method of high-temperature stable slow-digesting starch of the present invention is characterized in that it comprises the following steps: gelatinization step: gelatinizing the raw material starch, water and hydrocolloid to obtain a gelatinized starch mixture; separation step: gelatinizing the obtained paste The high temperature stable slowly digestible starch is obtained by separating the starch mixture.

[0066] In the preparation method of the present invention, the gelatinization (Gelatinization) refers to the gelatinization of starch, which is to mix the starch in water and heat. After reaching certain conditions, the starch granules will swell and collapse to form a thick and uniform transparent paste. solution.

[0067] The essence of starch gelatinization is that water enters the microcrystalline bundles, breaks the association state between starch molecules, makes ...

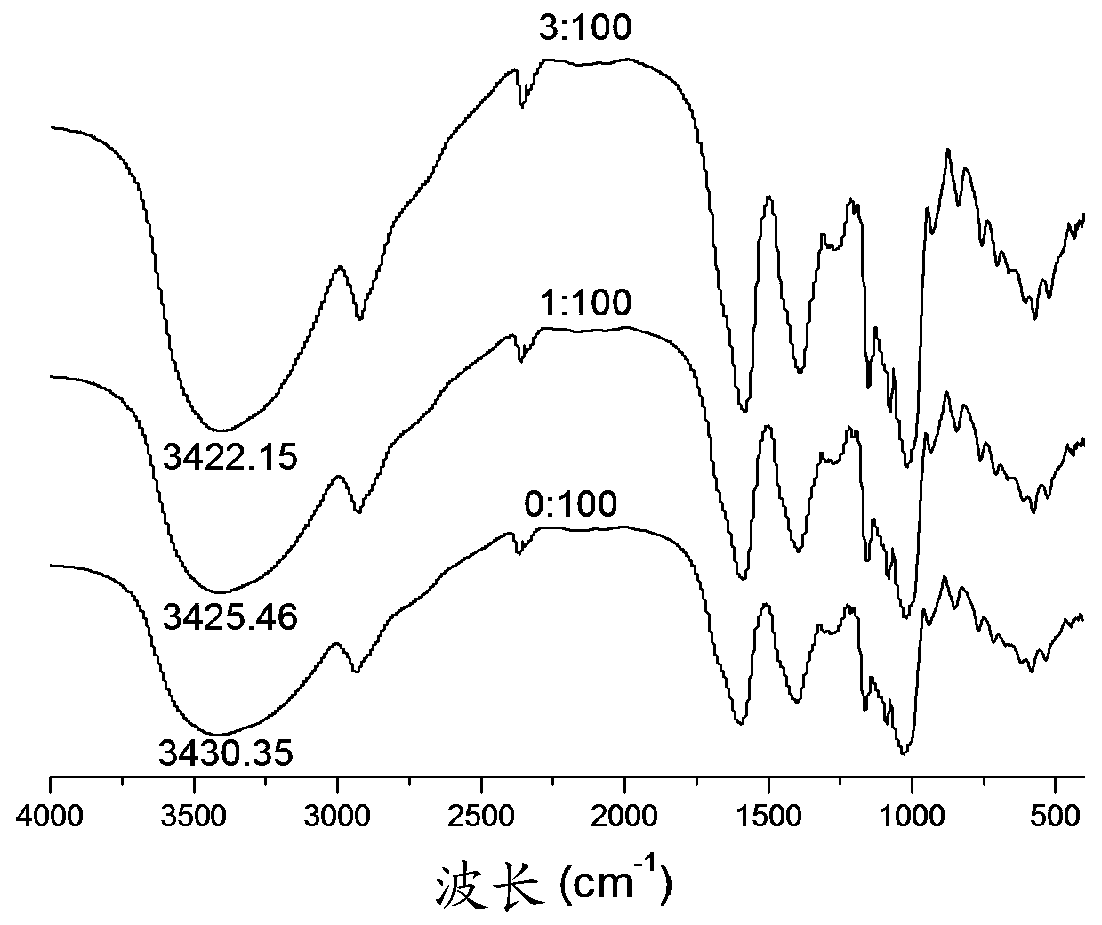

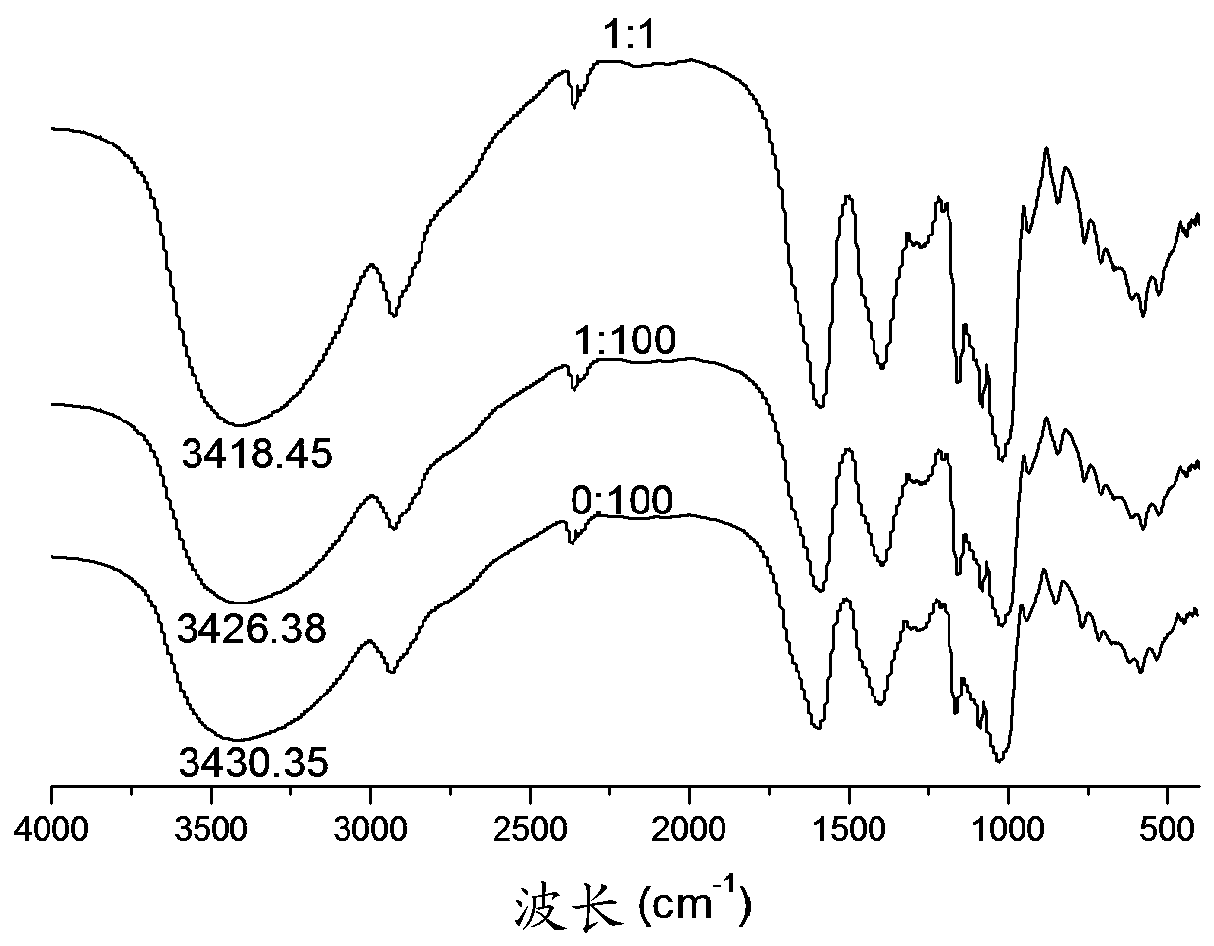

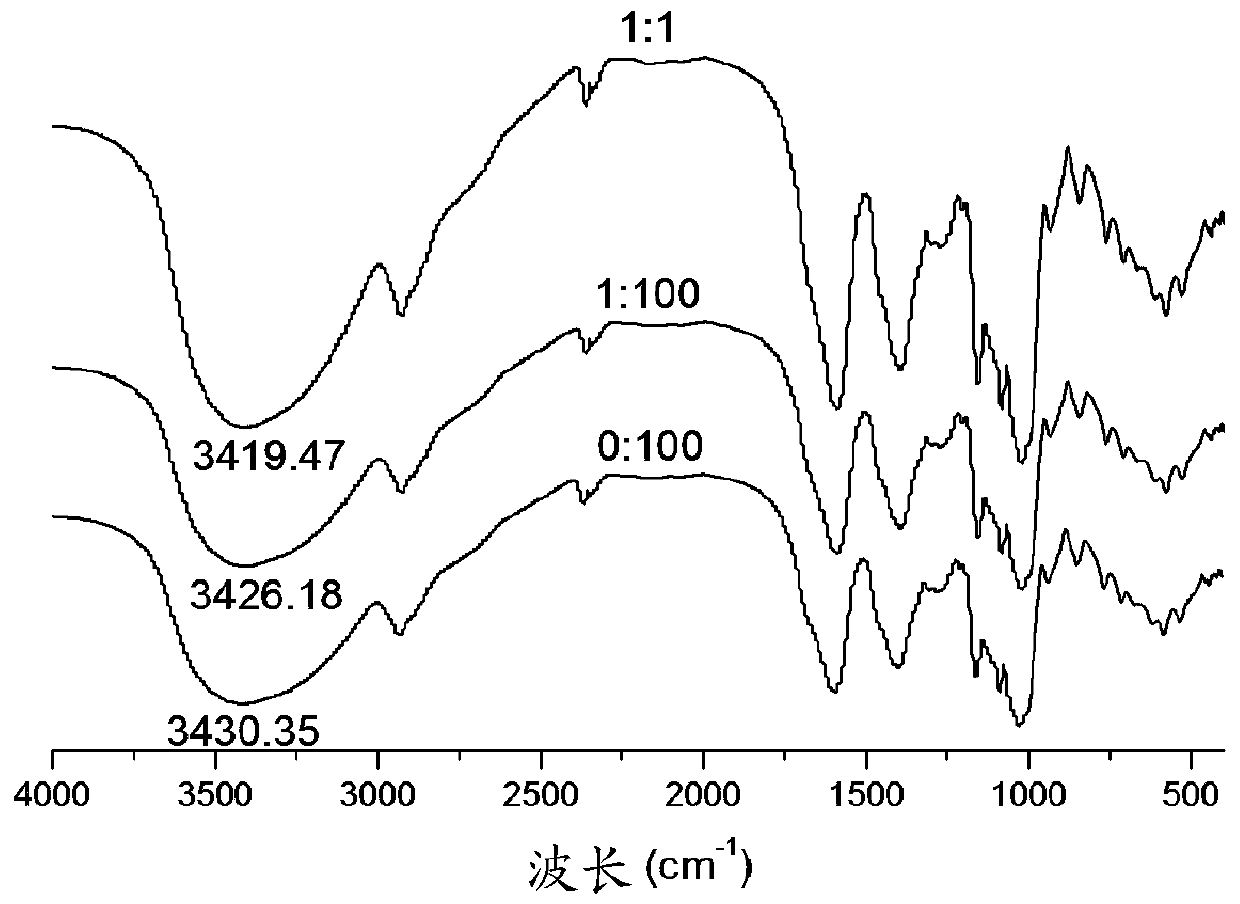

Embodiment 1-1

[0135] Take 0.01g of curdlan gum, stir and dissolve it in 100ml of NaOH solution with pH=11 at room temperature. Another 1 g of corn starch was taken, placed in curdlan gum aqueous solution, heated up to 90°C, and fully stirred for 8 minutes. Under these conditions, the above solution was rapidly heated to 100°C, and the solvent was evaporated to dryness within 50 seconds. Disperse and dissolve the obtained solute in 100ml water at 85°C, adjust the pH of the above mixed solution to 7 with 0.5mol / L citric acid solution, centrifuge at 6000rpm for 6min in a high temperature environment, dry the centrifuged precipitate in a freeze dryer for 24h, and pulverize , through a 100-mesh standard sieve.

Embodiment 1-2

[0137] The experimental conditions were the same as in Example 1-1, except that the added amount of curdlan gum was 0.3 g, and the added amount of cornstarch was 10 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com