Hydrophobic polyethylene masterbatch and application thereof in plastic greenhouse film

A polyethylene and hydrophobic technology, which can be used in climate change adaptation, horticulture, botanical equipment and methods, etc., can solve the problems of poor hydrophobicity of polyethylene film and affect the light transmittance of greenhouse film, etc., achieve good hydrophobic effect and improve quality , Improve the effect of daylighting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

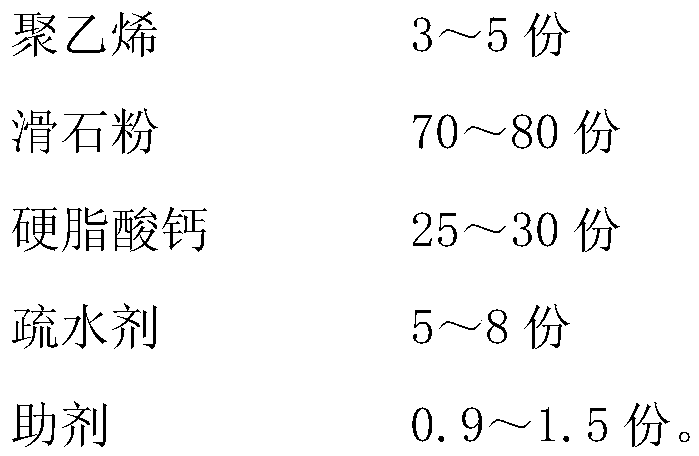

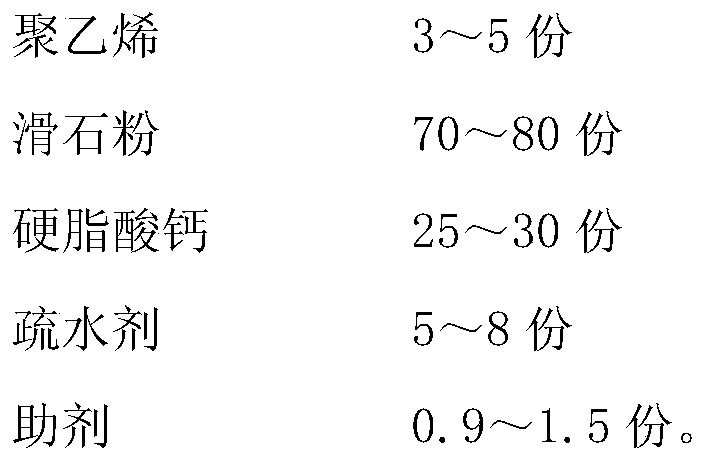

[0016] Embodiment 1 discloses a kind of hydrophobic polyethylene master batch, including raw material polyethylene, talc powder, calcium stearate, hydrophobic agent and auxiliary agent, the weight components of raw material are: polyethylene 3 parts, talcum powder 70 parts, 25 parts of calcium stearate, 5 parts of hydrophobic agent, and 0.9 parts of auxiliary agent.

[0017] The hydrophobic agent in this embodiment is a mixture of VAE emulsion and emulsion additives, and the two are mixed according to the volume ratio of 5:1. The emulsion additive is glyoxal. The hydrophobic agent also includes 0.5 parts by weight of polyvinyl alcohol. The weight ratio of VAE emulsion to emulsion additive is 5:1. The auxiliary agent is a mixture of polyethylene wax, antioxidant 1010 and colorant titanium dioxide. And the weight ratio of polyethylene wax:antioxidant:colorant is 1:3:5.

[0018] At the same time, this example also discloses a method for preparing a hydrophobic polyethylene gr...

Embodiment 2

[0020] Embodiment 2 discloses a kind of hydrophobic polyethylene master batch, including raw material polyethylene, talcum powder, calcium stearate, hydrophobic agent and auxiliary agent, the weight components of raw material are: polyethylene 5 parts, talc powder 80 parts, 30 parts of calcium stearate, 8 parts of hydrophobic agent, 1.5 parts of auxiliary agent.

[0021] The hydrophobic agent in this embodiment is a mixture of VAE emulsion and emulsion additives. The emulsion additive is phenolic resin. The hydrophobic agent also includes 1 part by weight of polyvinyl alcohol. The weight ratio of VAE emulsion to emulsion additive is 5:1. The auxiliary agent is a mixture of polyethylene wax, antioxidant 168 and colorant titanium dioxide. And the weight ratio of polyethylene wax:antioxidant:colorant is 1:3:5. The preparation method of the greenhouse film in this embodiment is the same as above. In early spring, when the humidity and temperature difference between inside and...

Embodiment 3

[0023] Embodiment 3 discloses a kind of hydrophobic polyethylene master batch, including raw material polyethylene, talcum powder, calcium stearate, hydrophobic agent and auxiliary agent, the weight component of raw material is: polyethylene 5 parts, talcum powder 80 parts, 30 parts of calcium stearate, 5 parts of hydrophobic agent, 0.9 parts of auxiliary agent.

[0024] The hydrophobic agent in this embodiment is a mixture of VAE emulsion and emulsion additives. The emulsion additive is melamine. The hydrophobic agent also includes 1 part by weight of polyvinyl alcohol. The weight ratio of VAE emulsion to emulsion additive is 4:1. The additive is a mixture of polyethylene wax, antioxidant and colorant. And the weight ratio of polyethylene wax:antioxidant:colorant is 1:3:5. During the test, greenhouse growers in Fanchang County, Anhui Province were selected. In November, when the humidity and temperature difference between the inside and outside of the greenhouse were larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com