Semitransparent color PET processing method

A processing method and translucent technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that electroplating cannot achieve translucent color, salt spray test has oxidation risk, etc. To avoid the risk of oxidation, improve the antioxidant capacity, and achieve the effect of simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

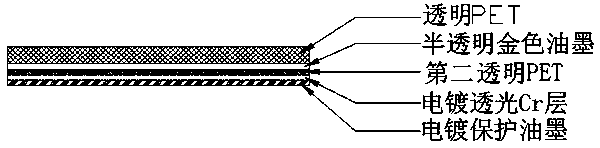

[0020] A processing method for translucent color PET, printing translucent colored ink on the back of the transparent PET to form a colored ink layer; bonding another layer of transparent PET to the surface of the colored ink layer to form a second transparent PET layer; The surface of the PET layer is silver-plated to form a silver-plated layer; the transparent electroplating protective ink is printed on the surface of the silver-plated layer to obtain such as figure 1 PET in translucent colors shown.

[0021] Wherein, the silver component is Cr; the thickness of the second transparent PET layer is 0.025mm.

[0022] The electroplating protective ink includes the following raw materials in parts by weight: 60 parts of acrylic resin, 10 parts of polyvinyl alcohol, 10 parts of polysiloxane, 1 part of stearamide, 1 part of chitosan, 2 parts of sodium carboxymethyl cellulose 3 parts and 3 parts of antioxidant. The electroplating protective ink is obtained through the following s...

Embodiment 2

[0025] A processing method for translucent color PET, printing translucent colored ink on the back of the transparent PET to form a colored ink layer; bonding another layer of transparent PET to the surface of the colored ink layer to form a second transparent PET layer; The surface of the PET layer is electroplated with silver to form an electroplated silver layer; transparent electroplating protective ink is printed on the surface of the electroplated silver layer.

[0026] Wherein, the silver component is Cr; the thickness of the second transparent PET layer is 0.02-0.03mm.

[0027] The electroplating protective ink includes the following raw materials in parts by weight: 60 parts of acrylic resin, 15 parts of polyvinyl alcohol, 5 parts of polysiloxane, 4 parts of stearamide, 4 parts of chitosan, 2 parts of sodium carboxymethyl cellulose and 1 part of antioxidant. The electroplating protective ink is obtained through the following steps: acrylic resin, polyvinyl alcohol an...

Embodiment 3

[0030] A processing method for translucent color PET, printing translucent colored ink on the back of the transparent PET to form a colored ink layer; bonding another layer of transparent PET to the surface of the colored ink layer to form a second transparent PET layer; The surface of the PET layer is electroplated with silver to form an electroplated silver layer; transparent electroplating protective ink is printed on the surface of the electroplated silver layer.

[0031] Wherein, the silver component is Cr; the thickness of the second transparent PET layer is 0.02-0.03mm.

[0032] The electroplating protective ink includes the following raw materials in parts by weight: 56 parts of acrylic resin, 12 parts of polyvinyl alcohol, 7 parts of polysiloxane, 3 parts of stearamide, 3 parts of chitosan, 5 parts of sodium carboxymethyl cellulose 2 parts and 2 parts of antioxidant. The electroplating protective ink is obtained through the following steps: acrylic resin, polyvinyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com