A kind of dismantling and debonding method of sapphire wafer and metal parts

A technology for sapphire wafers and metal parts, which is applied in the field of disassembly and degumming of sapphire wafers and metal parts, can solve problems such as inability to use Haval glue to disassemble and degumming, and achieves a solution that reduces the risk of falling off, improves work efficiency, and has high drying efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

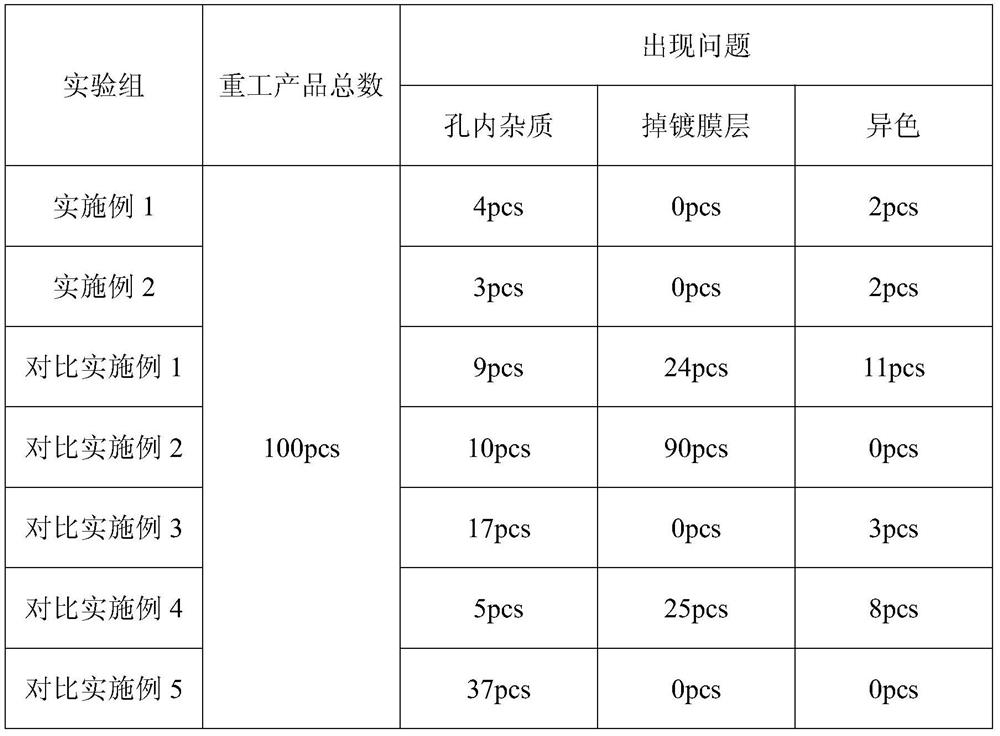

Examples

Embodiment 1

[0028] A dismantling and debonding method of a sapphire wafer and a metal part, comprising the steps of:

[0029] Step 1): Place the camera product to be reworked on the special graphite fixture of the hot bending machine, keep the flow rate of nitrogen gas at 130±0.5L / min, and heat at 350°C for 30min to make the Haval glue layer occur Carbonization, at this time, a gap is formed between the sapphire wafer and the metal part.

[0030] Step 2): Soak the camera that has completed step 1) in a container filled with degumming potion, so that the carbonized adhesive layer and ink fall off or dissolve in the degumming potion. The temperature of the degumming potion is 70°C and the degumming time is 60 minutes. , Cooperate with ultrasonic synchronization when degumming.

[0031] Step 3): Place the metal parts that have completed step 2) on the Teflon fixture and put them into a single-slot ultrasonic cleaning basket, add pure water with a resistance of not less than 15MΩ and keep th...

Embodiment 2

[0035] The difference from Example 1 is that the degumming solution used is the PA-3302 type degumming solution purchased from Hunan Lier Electronic Materials Co., Ltd., its pH value is 7 and the specific components include 20% methyl ethyl alcohol base ketone, 10% xylene, 10% N,N-dimethylformamide, 5% acetone and 55% ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com