Preparation method of particle-reinforced medical magnesium-based composite material

A particle-reinforced, composite material technology is applied in the field of preparation of particle-reinforced medical magnesium-based composite materials. , The effect of low processing cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

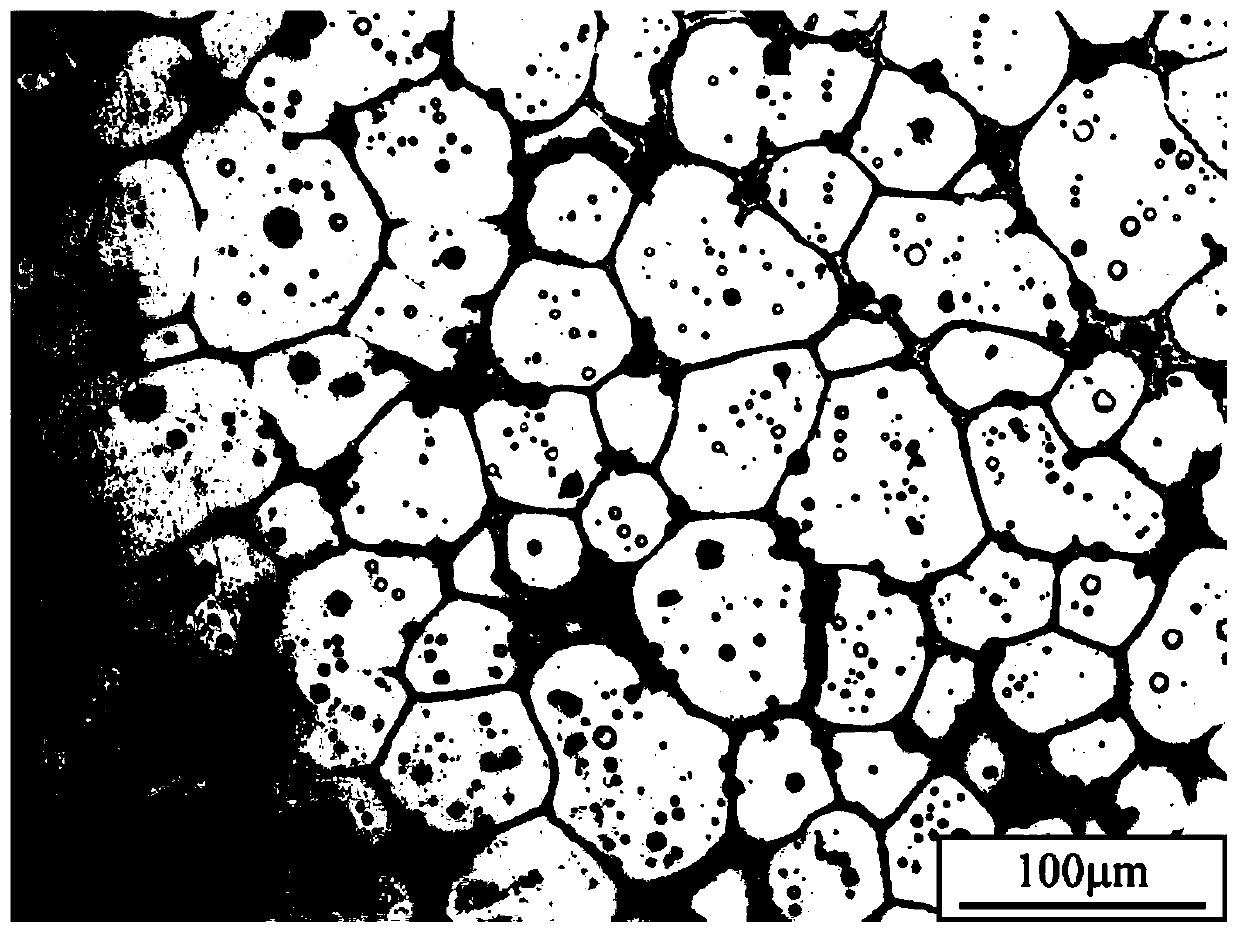

Embodiment 1

[0037] This example provides a method for preparing a particle-reinforced medical magnesium-based composite material, including the following steps:

[0038] S1: Put the preheated AZ31 magnesium alloy into a container, heat and melt it under a protective atmosphere, and obtain a magnesium alloy melt in a molten state;

[0039] S2: After adding high-purity Si fine powder to the magnesium alloy melt obtained in step S1, the melt is heated up, and left standing for the first time under a protective atmosphere;

[0040] S3: After the magnesium alloy melt obtained in step S2 is subjected to vacuum electromagnetic stirring, the surface scum is removed, and the second standing is carried out under a protective atmosphere;

[0041] S4: After removing surface dross from the magnesium alloy melt obtained in step S3, cooling the melt, and pouring it into a mold to obtain an ingot;

[0042] S5: Put the ingot obtained in step S4 into a box-type resistance furnace, and perform solution agi...

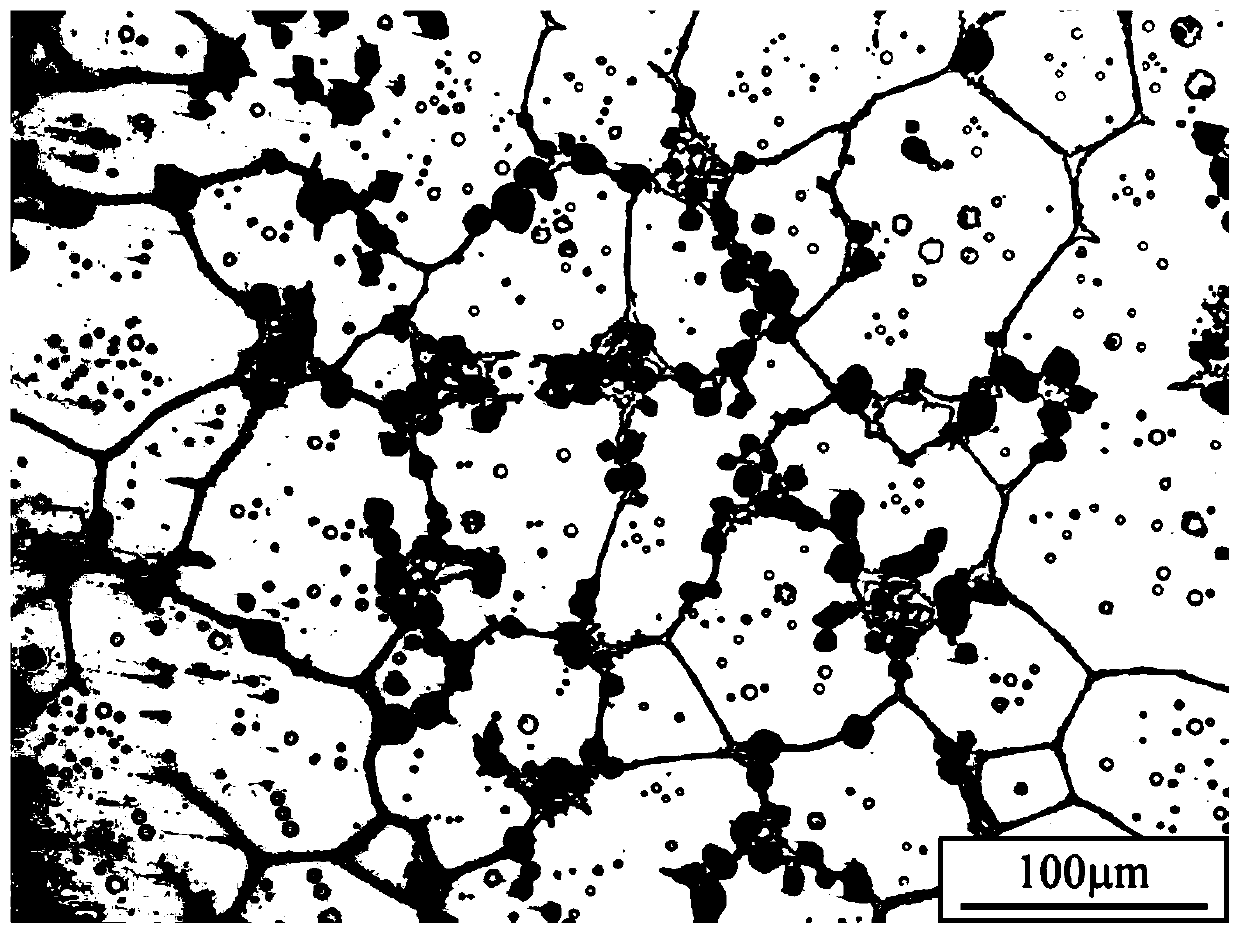

Embodiment 2

[0051] In this example, a particle-reinforced medical magnesium-based composite material is actually prepared, and the specific steps include:

[0052] (1) Cut and weigh the cleaned AZ31 magnesium alloy according to the proportion, and then put it into a vacuum drying oven for preheating treatment, wherein the preheating temperature is 200°C, and the preheating time is 2h;

[0053] (2) Put the preheated AZ31 magnesium alloy into a high-frequency resistance melting furnace, and then under the protection of tetrafluoroethane gas, melt the AZ31 magnesium alloy when it is heated to 650°C;

[0054] (3) adding 0.5wt.% high-purity Si fine powder to the melted magnesium alloy melt, then raising the temperature of the melt to 740° C., and standing still for 30 minutes under the protection of tetrafluoroethane gas;

[0055] (4) Stir the melt after standing for 20 minutes by vacuum electromagnetic mode, then remove the scum on the surface of the melt, and stand for 20 minutes under the p...

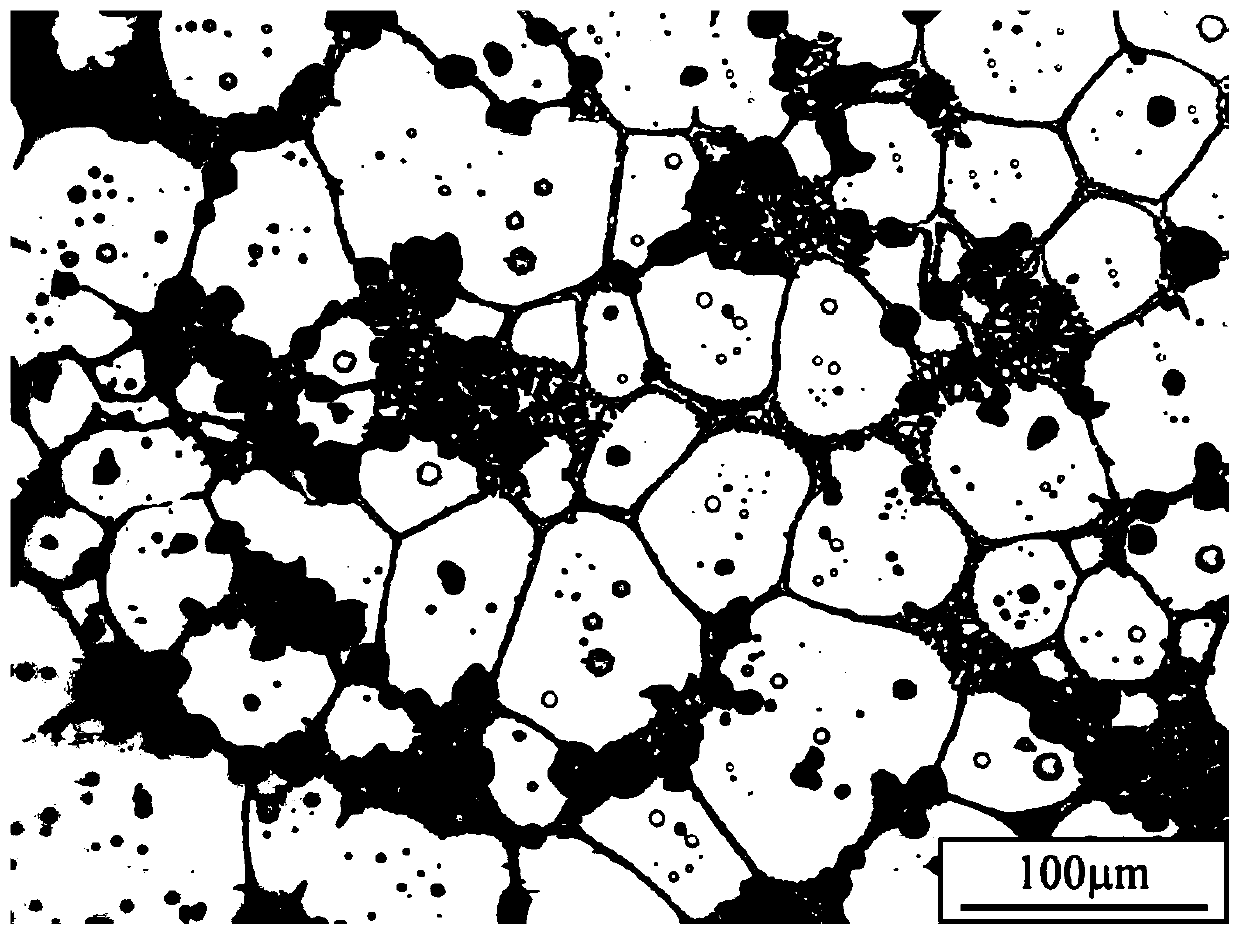

Embodiment 3

[0061] In this example, a particle-reinforced medical magnesium-based composite material is actually prepared, and the specific steps include:

[0062] (1) Cut and weigh the cleaned AZ31 magnesium alloy according to the proportion, and then put it into a vacuum drying oven for preheating treatment, wherein the preheating temperature is 200°C, and the preheating time is 2h;

[0063] (2) Put the preheated AZ31 magnesium alloy into a high-frequency resistance melting furnace, and then under the protection of tetrafluoroethane gas, melt the AZ31 magnesium alloy when it is heated to 660°C;

[0064] (3) adding 1.5wt.% high-purity Si fine powder into the melted magnesium alloy melt, and then raising the temperature of the melt to 750° C., and standing still for 40 minutes under the protection of tetrafluoroethane gas;

[0065] (4) Stir the melt after standing still for 30min by vacuum electromagnetic mode, then remove the scum on the surface of the melt, and stand still for 25min und...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com