Cutter suction dredger lateral moving automatic controller

A technology of automatic controller and cutter suction dredger, which is applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., which can solve the problem of unmatched cable speed of anchor winch and the influence of dredging Problems such as ship construction output and low concentration of transported mud have achieved the effects of improving construction quality and dredging efficiency, reducing operational differences, and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

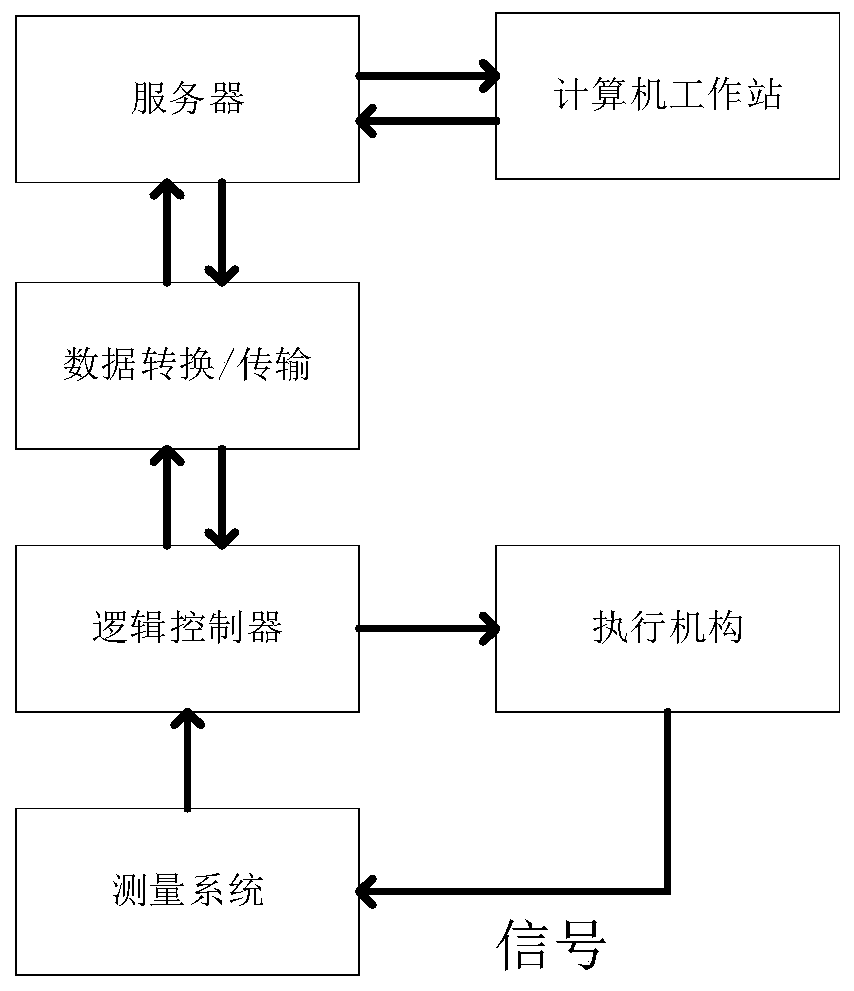

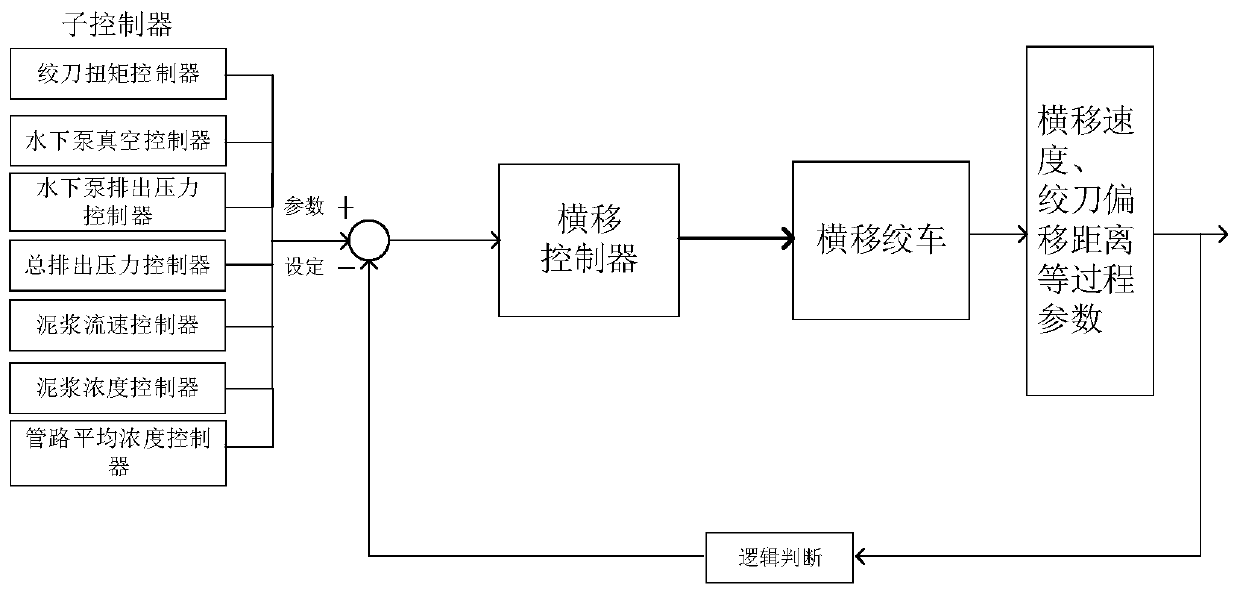

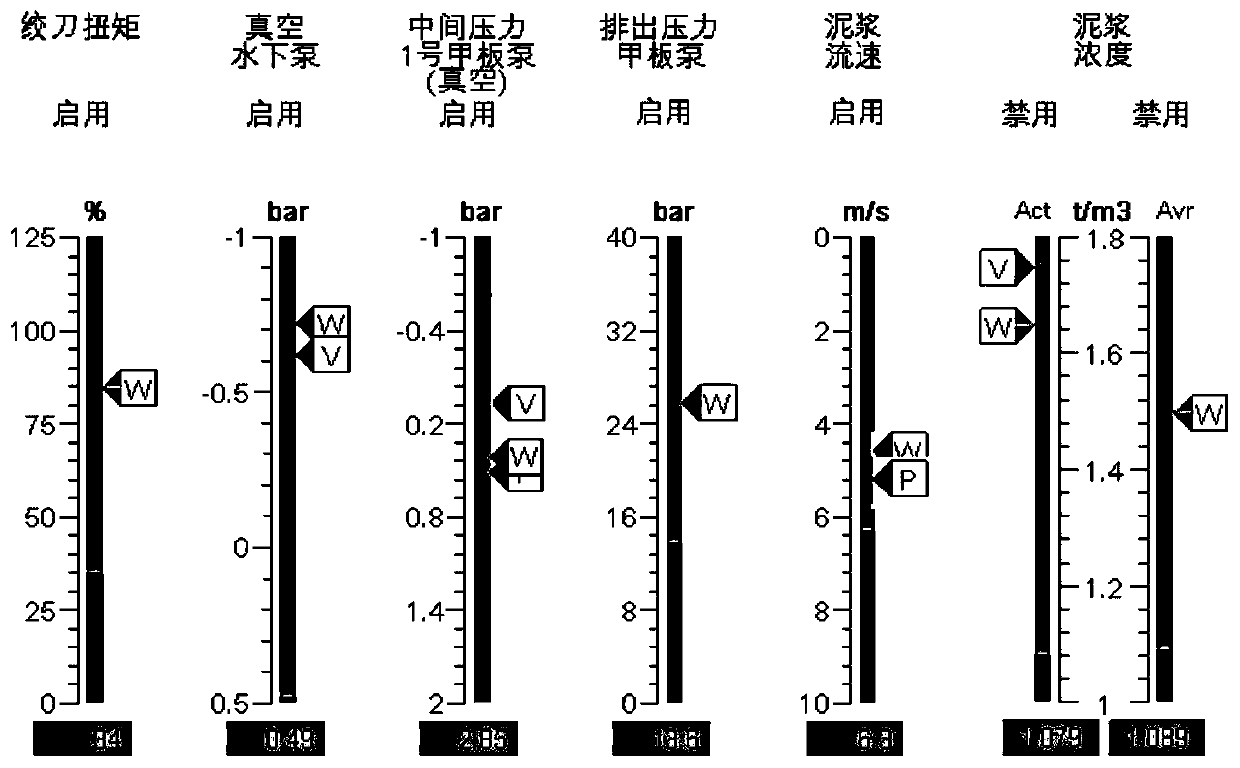

[0027] An automatic traverse controller of a cutter suction dredger, the automatic traverse controller is composed of seven sub-controllers, namely: reamer torque controller, underwater pump vacuum controller, underwater pump discharge pressure controller, The total discharge pressure controller, the mud flow rate controller, the mud concentration controller, and the pipeline average concentration controller; the traverse speed control of the traverse winch is controlled through the linkage control of each sub-controller, specifically: the traverse speed is linked with the reamer torque Control, linkage control of traverse speed and vacuum degree of underwater pump, linkage control of traverse speed and discharge pressure of underwater pump, linkage control of traverse speed and total discharge pressure, linkage control of traverse speed and mud flow rate, linkage control of traverse speed and mud Concentration linkage control, traverse speed and pipeline average concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com