Preparation method of automobile door frame integrally thermoformed by light-weight dissimilar steel

A dissimilar steel and hot forming technology, which is applied in the field of auto parts, can solve the problems of poor formability, surface wrinkles, and easy cracking of high-strength steel, and achieve the effects of high forming accuracy, no springback, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

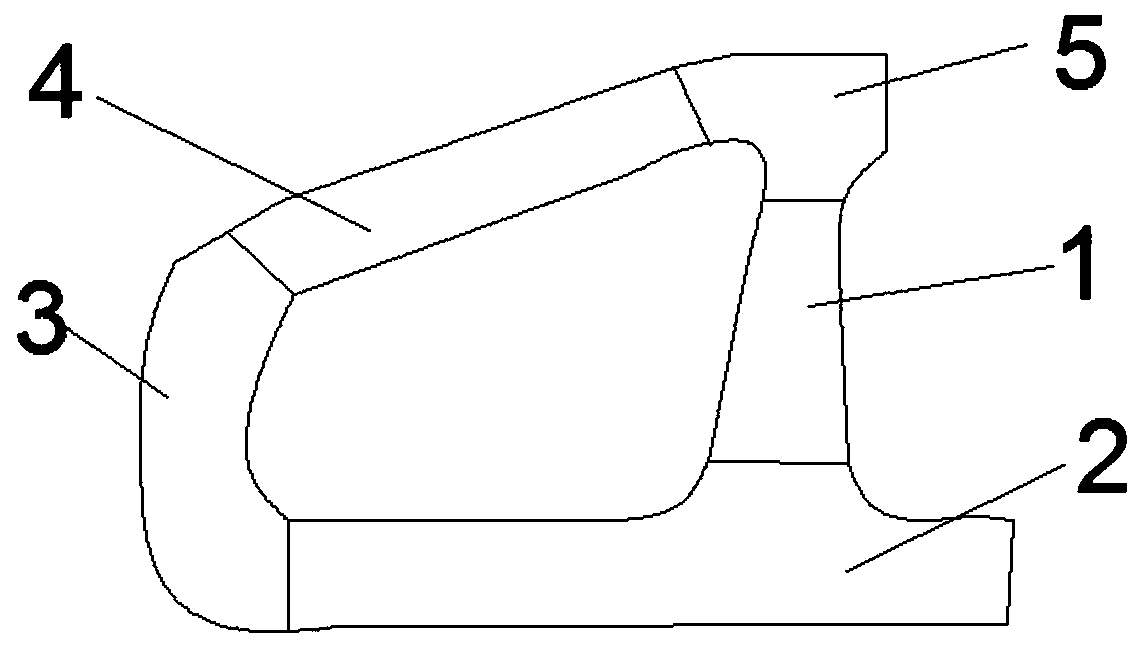

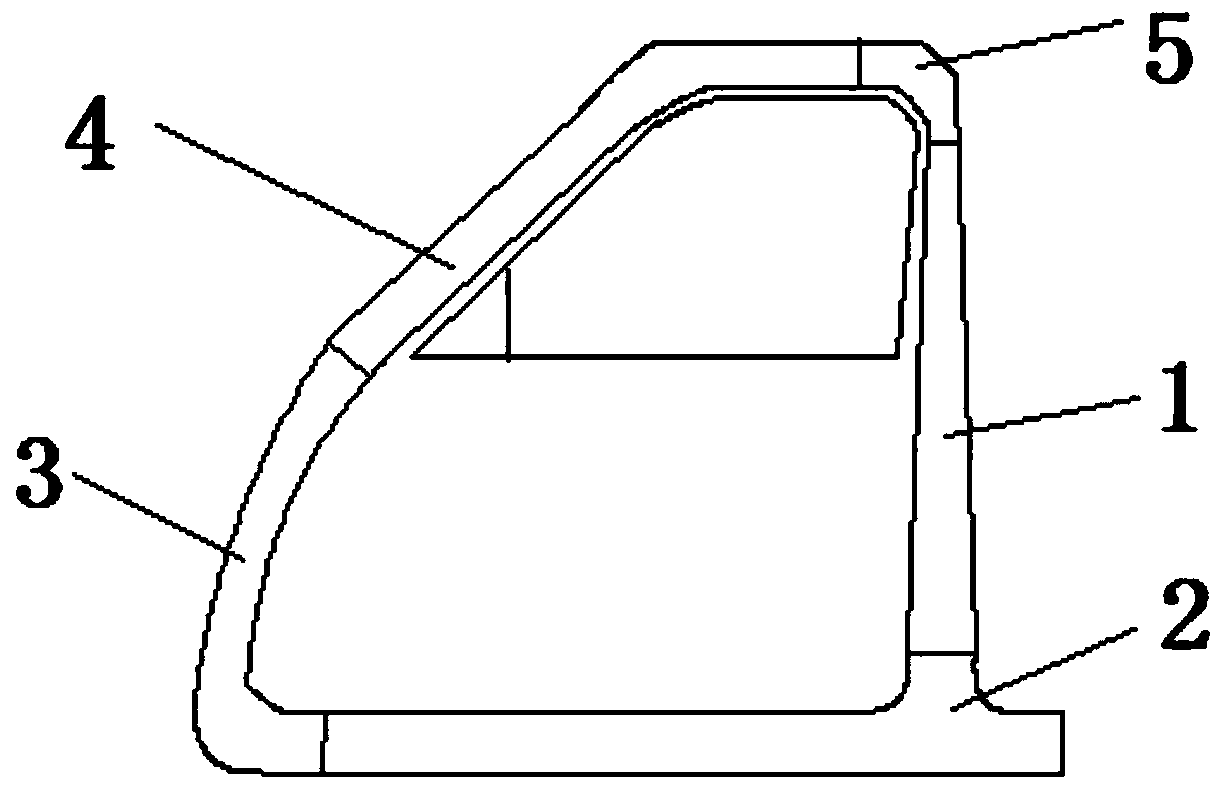

[0019] Such as figure 1 As shown, the whole door frame is divided into five parts, which are respectively a right vertical frame 1, a lower horizontal frame 2, a left vertical frame 3, a left oblique frame 4 and an upper horizontal frame 5. Different high-strength steel plates are used. Figure 1 The middle right vertical frame 1 and left vertical frame 3 are made of hot-formed steel plate 22MnB5, the lower horizontal frame 2 is made of DP590 steel plate, the left oblique frame 4 is made of QP980 steel plate, and the upper horizontal frame 5 is made of IF steel.

[0020] The right vertical frame 1 and the left vertical frame 3 of the present invention are partly made of hot-formed steel plate 22MnB5 with a thickness of 1.5mm produced by Baosteel, whose composition is 0.22C-0.92Mn-0.17Si (wt.%), and whose strength is at the level of 1500MPa , the elong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com