Preparation method of environment-friendly silicone rubber foaming tube

A production method and technology of silicone rubber, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of weather resistance, high and low temperature resistance, hidden dangers of personal safety, and the influence of gripping force, etc., and achieve good resilience. , Good physical comprehensive performance, simple disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

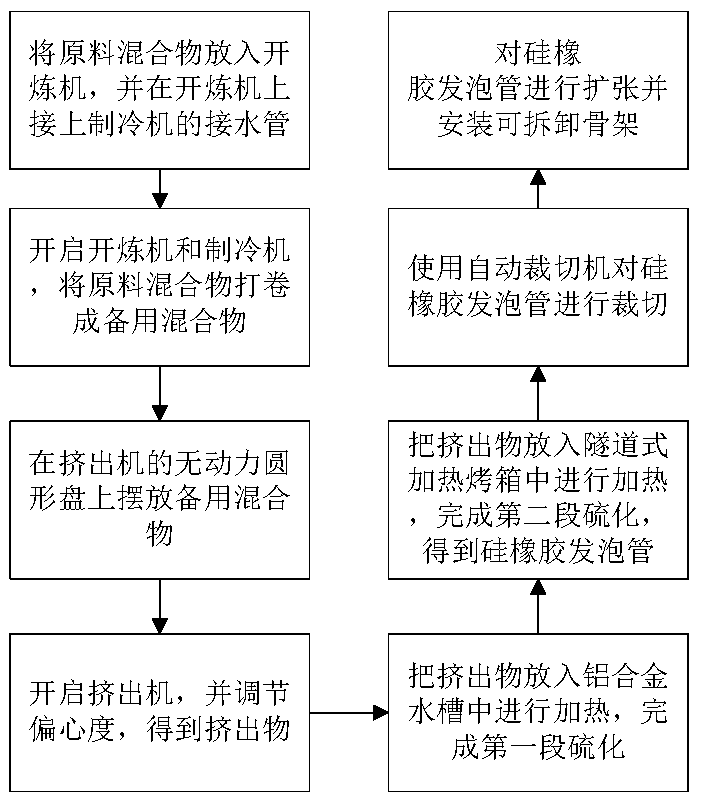

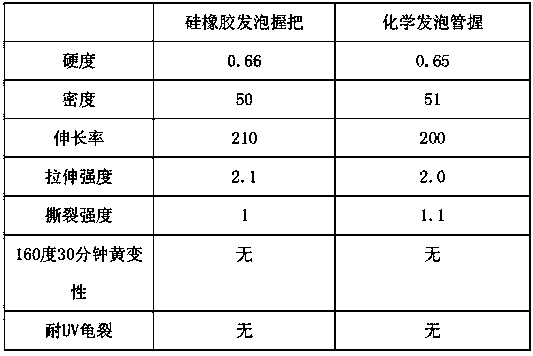

[0030] Such as figure 1 As shown, in this embodiment, a method for making an environmentally friendly silicone rubber foam tube includes the following steps: putting the raw material mixture into an open mill, and connecting the water connection pipe of the refrigerator to the open mill; Mixing machine and refrigerator, roll the raw material mixture into a standby mixture; place the standby mixture on the unpowered circular disk of the extruder; turn on the extruder, and adjust the eccentricity to obtain the extrudate; put the extrudate Put it in an aluminum alloy water tank for heating to complete the first stage of vulcanization; put the extruded product into a tunnel heating oven for heating to complete the second stage of vulcanization to obtain a silicone rubber foam tube; use an automatic cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com