Method for preparing Al2O3-GdAlO3-ZrO2 ternary eutectic ceramics

A ternary eutectic, ceramic technology, used in ceramic molding machines, manufacturing tools, additive processing, etc., can solve the problems of long processing cycle, high production cost, and complicated procedures in the forming process, and shorten the preparation cycle and forming speed. Quick, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

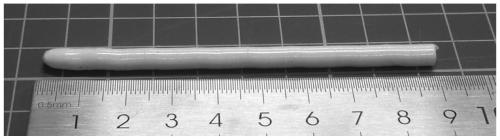

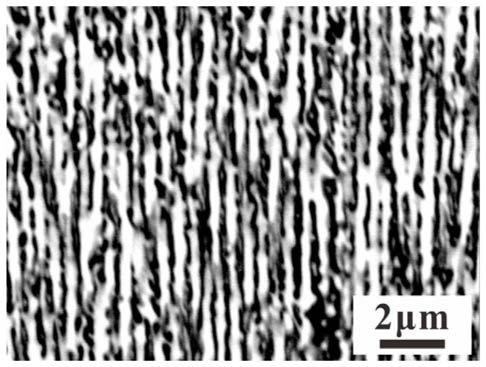

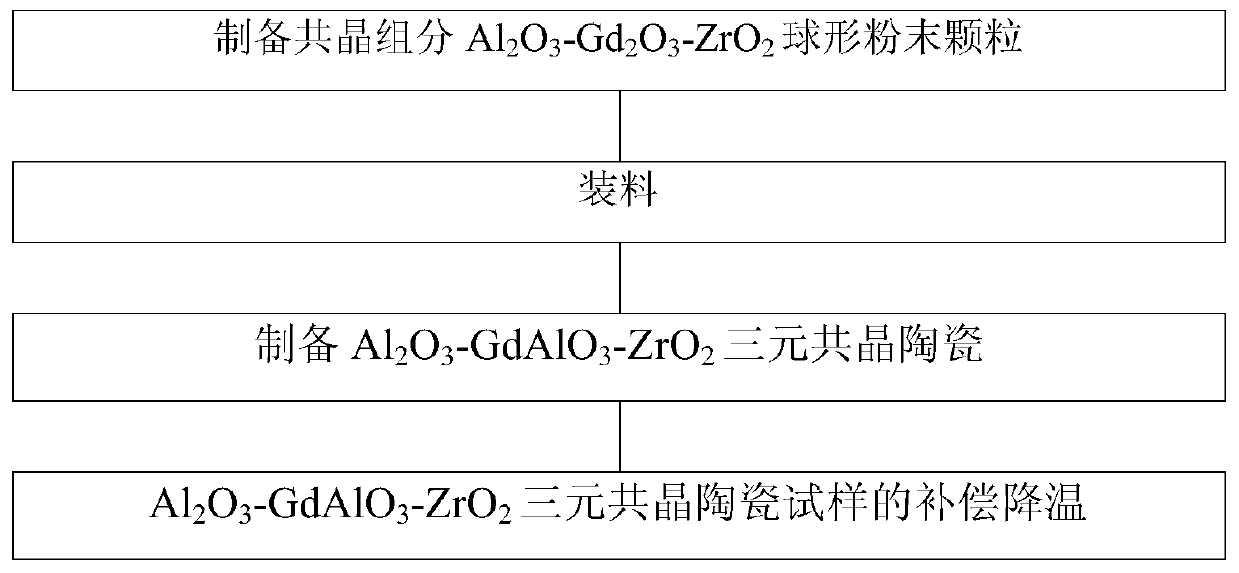

[0037] The invention is a method of manufacturing Al by laser near-net shape 2 o 3 -GdAlO 3 -ZrO 2 The method for ternary eutectic ceramics, the concrete process comprises the following steps:

[0038] Step 1, preparation of eutectic composition Al 2 o 3 -Gd 2 o 3 -ZrO 2 Spherical powder particles.

[0039] Using the centrifugal spray drying method, the Al 2 o 3 -Gd 2 o 3 -ZrO 2 Ceramic powders are prepared as spherical powder particles.

[0040] The eutectic ratio is: Al 2 o 3 Powder is 58%, Gd 2 o 3 Powder is 19%, ZrO 2 Powder is 23%.

[0041] The ratios are molar percentages.

[0042] The method for preparing spherical powder particles is disclosed in the invention with application number CN201810640599, and the specific process is:

[0043] The first step is to obtain a fully mixed eutectic component oxide ceramic powder;

[0044] The eutectic component oxide ceramic powder is Al 2 o 3 Powder, Gd 2 o 3 Powder and ZrO 2 Powder is the starting mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com