Pressure sensitive adhesive for producing SPVC (soft polyvinyl chloride) electrical adhesive tapes and processing method of pressure sensitive adhesive

A soft polyvinyl chloride, pressure-sensitive adhesive technology, applied in the direction of adhesives, natural rubber adhesives, ester copolymer adhesives, etc., can solve the problems of waste of resources, pollution of the use environment, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

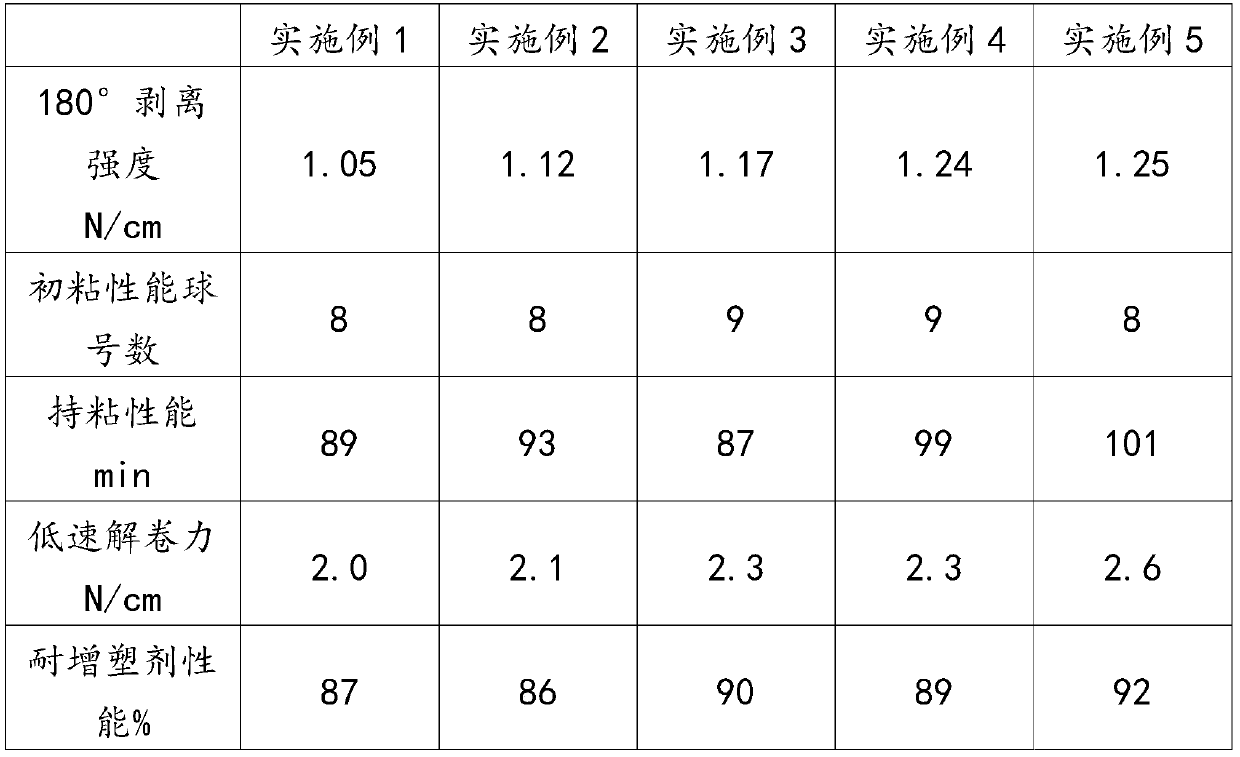

Examples

Embodiment 1

[0028] (1) Raw materials are prepared, wherein each raw material is proportioned in parts by weight, specifically as follows:

[0029] 30 parts by weight of viscosifying copolymer emulsion;

[0030] 75 parts of natural rubber latex;

[0031] 2 parts hindered phenolic antioxidant;

[0032] 3 parts dilauryl thiodipropionate;

[0033] (2) Mix the above raw materials evenly, and discharge to obtain a pressure-sensitive adhesive for making soft polyvinyl chloride electrical tape.

Embodiment 2

[0035] (1) Raw materials are prepared, wherein each raw material is proportioned in parts by weight, specifically as follows:

[0036] 35 parts by weight viscosity-increasing copolymer emulsion;

[0037] 70 parts of styrene-butadiene rubber latex (a stable emulsion formed by polymerization of butadiene and styrene at low temperature);

[0038] 2 parts hindered phenolic antioxidant;

[0039] 3 parts tetrakis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol;

[0040] (2) Mix the above raw materials evenly, and discharge to obtain a pressure-sensitive adhesive for making soft polyvinyl chloride electrical tape.

Embodiment 3

[0042] (1) Raw materials are prepared, wherein each raw material is proportioned in parts by weight, specifically as follows:

[0043] 40 parts by weight viscosity-increasing copolymer emulsion;

[0044] 65 parts of nitrile rubber latex (stable emulsion prepared by emulsion polymerization of butadiene and acrylonitrile);

[0045] 3 parts hindered phenolic antioxidant;

[0046] 2 parts of octadecyl β-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionate;

[0047] (2) Mix the above raw materials evenly, and discharge to obtain a kind of soft polyvinyl chloride electrical tape

[0048] pressure sensitive adhesives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com