Constant temperature flow microalgae photobioreactor

A technology of photobioreactor and photobioreaction, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, enzymology/microbiology device, etc. The overall productivity of the reactor, unstable culture conditions, and uneven light received by microalgae have achieved the effect of simple structure, ingenious combination, and uniform light intensity distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

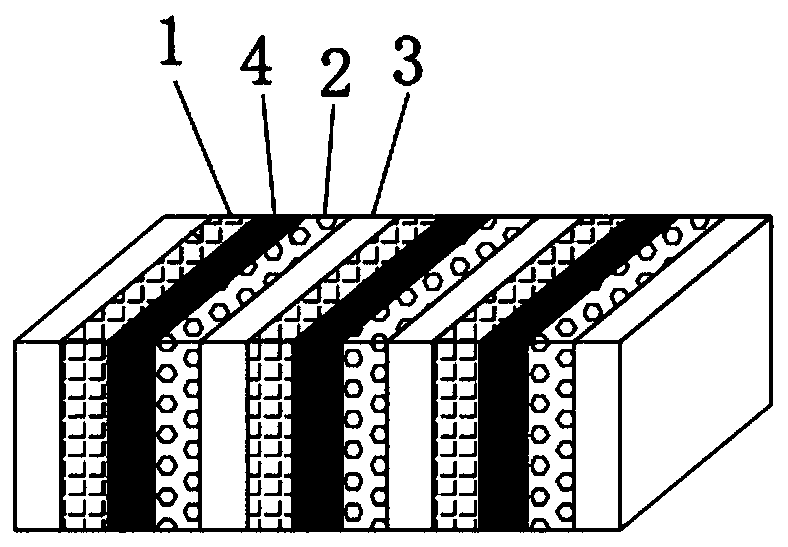

[0027] Such as figure 1 As shown, a constant-temperature flow type microalgae photobioreactor includes several A-type incubator units and B-type incubator units alternately arranged, each incubator unit includes successively attached photothermal phase change fluid temperature control parts 1. The metal spoiler baffle 4, the photobiological reaction part 2 and the light source part 3 are bonded together by a sealing ring and a sealant to achieve a better sealing effect.

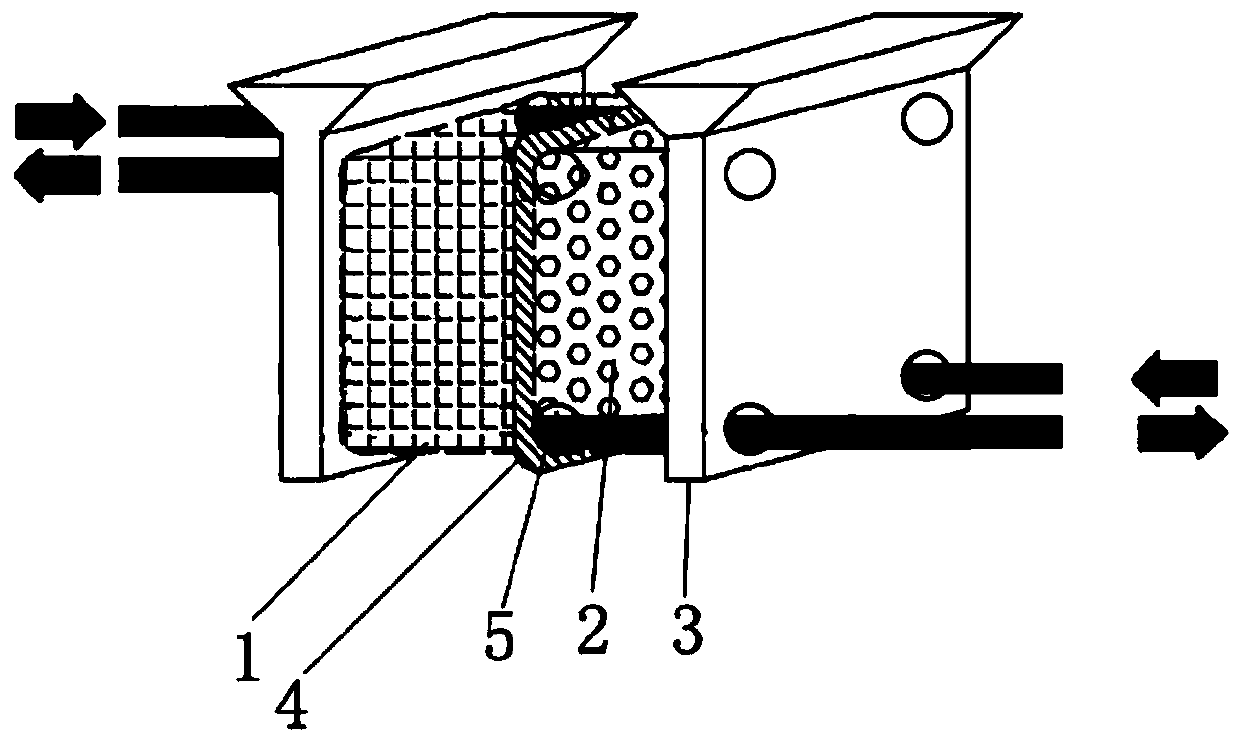

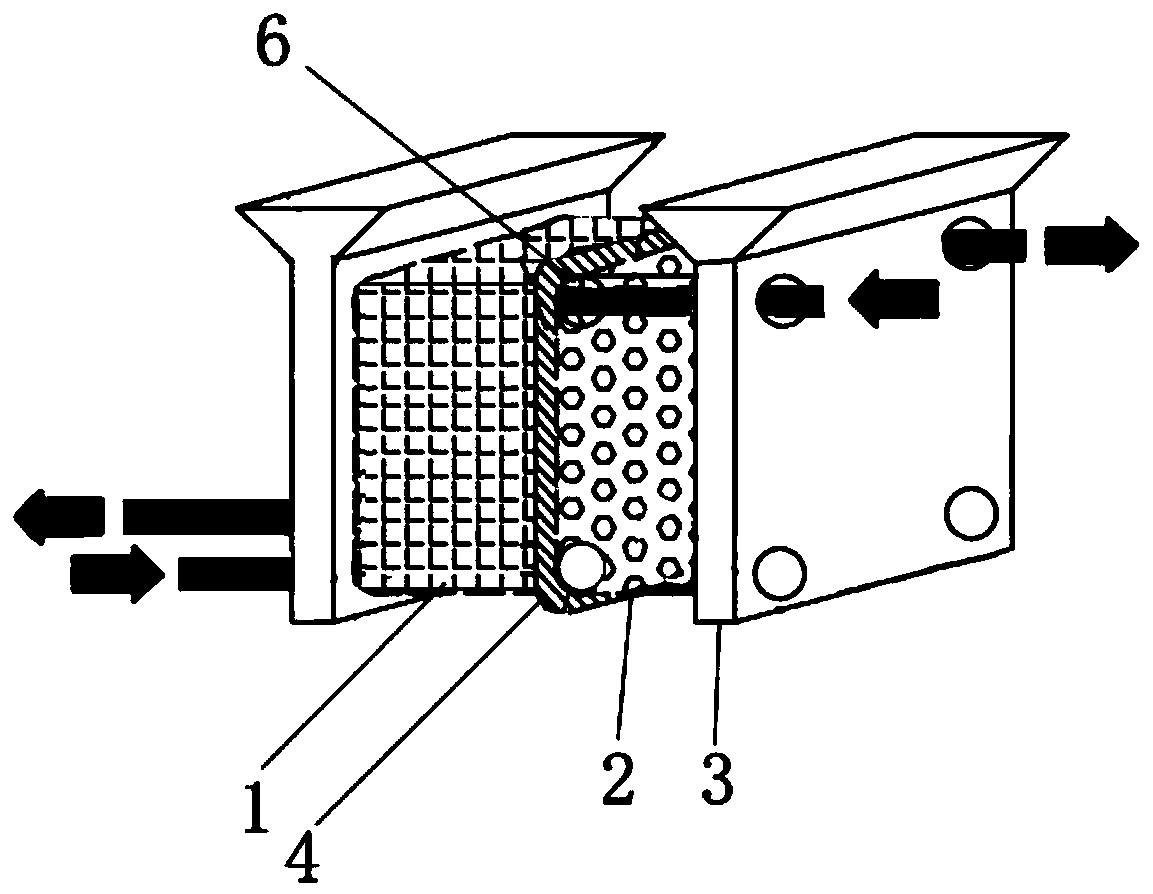

[0028] Such as Figure 2-4 As shown, the photothermal phase change fluid temperature control part of the A-type incubator unit has an inlet a18 at the lower right corner of the front, the opposite upper right corner of the photothermal phase change fluid temperature control part has an outlet a2, and the photobiological reaction part has an inlet a2 at the lower left corner of the front The exit a3 5, the upper left corner of the reverse side of the photobiological reaction part has an entrance a47. The phototh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com