Small rapid temperature rise and reduction annealing device suitable for quantum chip

An annealing device and heating and cooling technology, applied in the direction of furnace types, furnaces, heat treatment furnaces, etc., can solve the problems of slow cooling of the system, complex use of devices, and difficulty in heating the system that is easy to cool down, and achieve the effect of precise control of the heating and cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

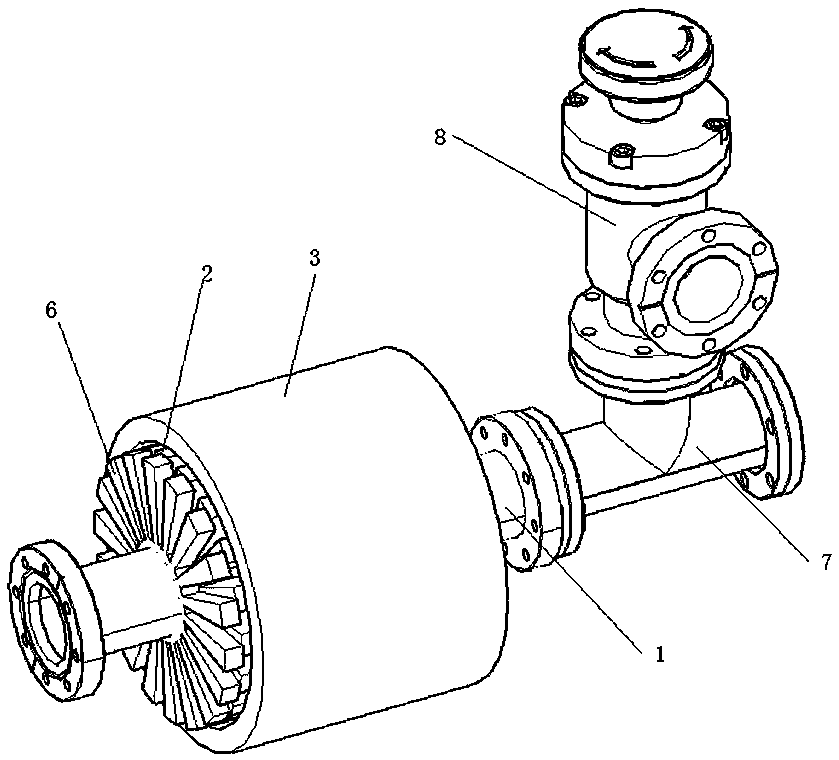

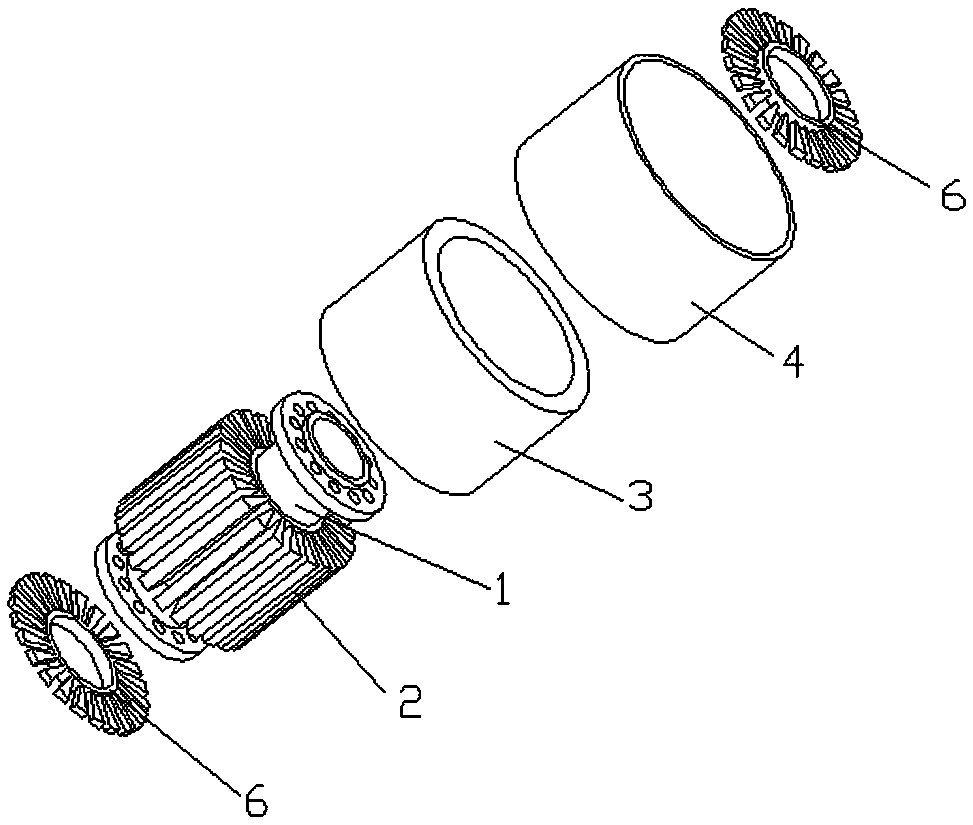

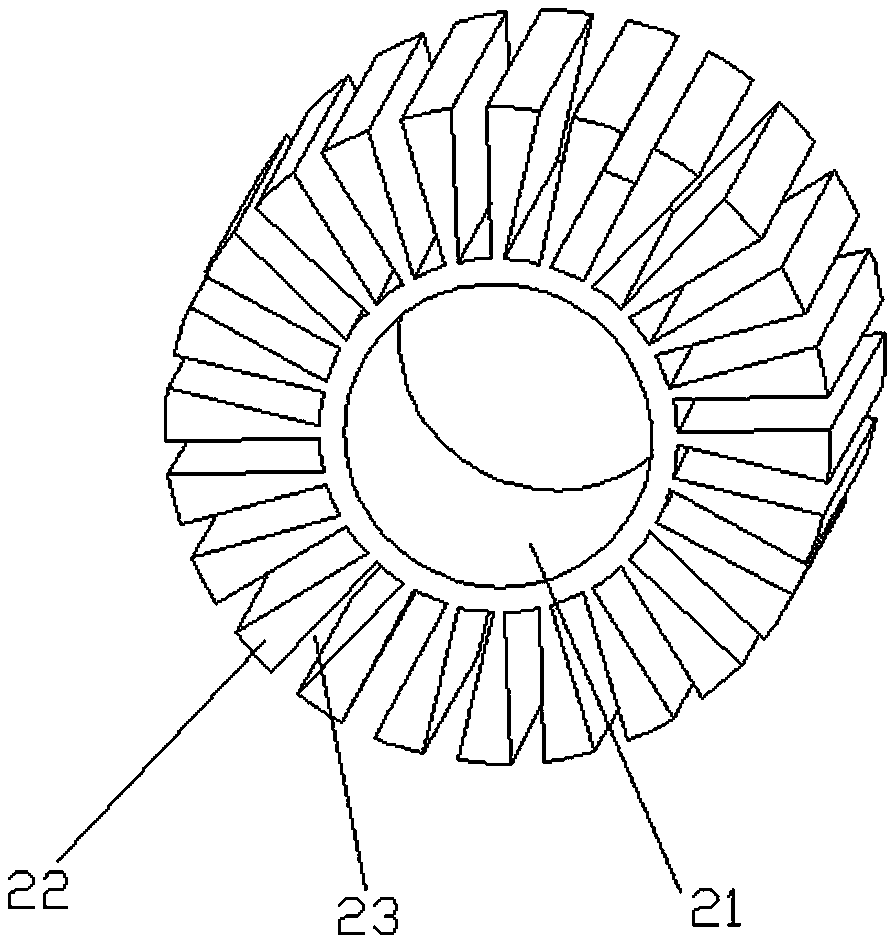

[0025] Such as figure 1 As shown, a rapid heating and cooling annealing device suitable for quantum chips includes a vacuum chamber 1, a gas flow control valve a is provided at one end of the vacuum chamber 1, and a tee 7 is connected at the other end. The top of the tee 7 is connected with a sealing angle valve 8, and the other end of the tee 7 is connected with an electric lead wire electrode. The electrical series lead electrode includes a flange and a transmission wire. The flange is used to seal the end of the tee 7 , and the transmission wire can transmit electrical signals from the airtight vacuum chamber 1 to the outside of the tee 7 . The other end of the sealing angle valve 8 is connected with a vacuum pump. When the flow contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com