Manufacturing method of elastic fabric

A technology of elastic fabrics and manufacturing methods, applied in fabrics, textiles, papermaking, textiles, etc., can solve problems such as easy uneven dyeing, high dyeing and finishing sensitivity, and white fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

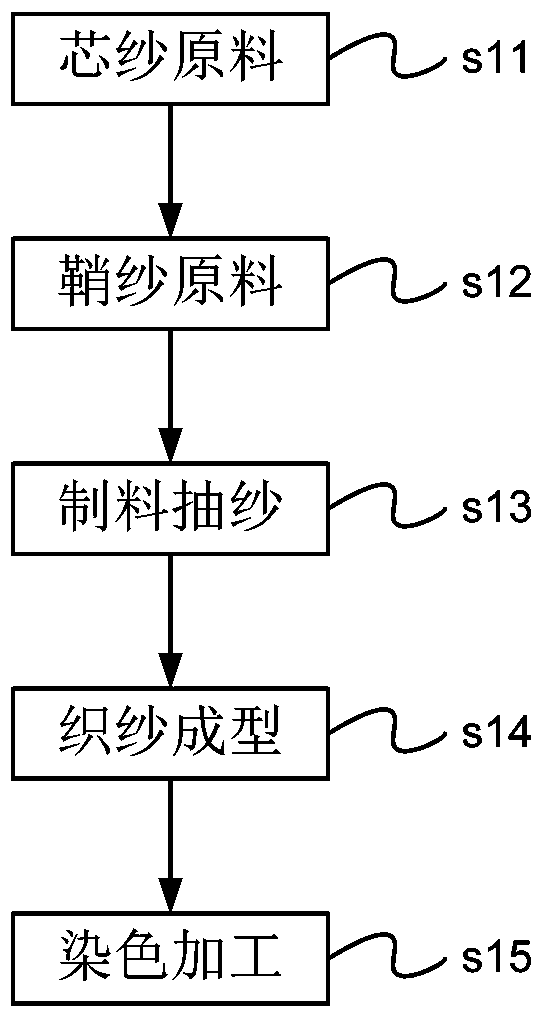

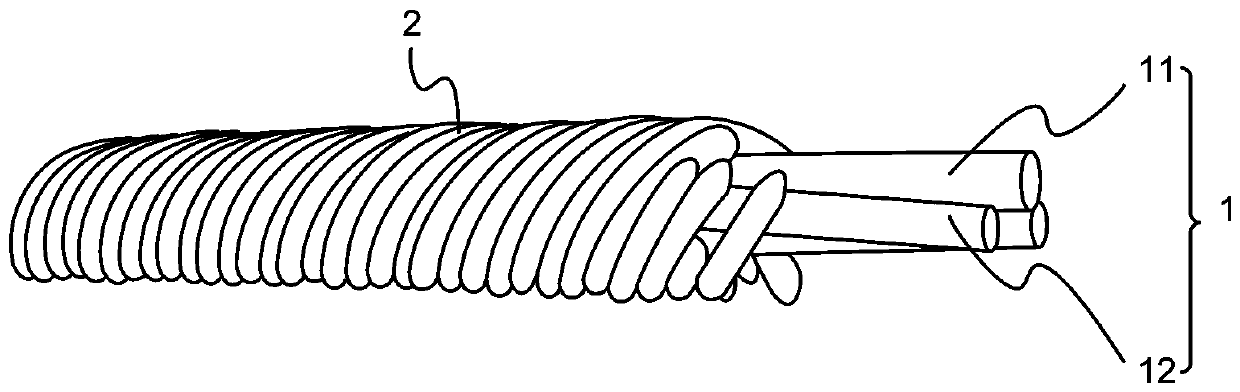

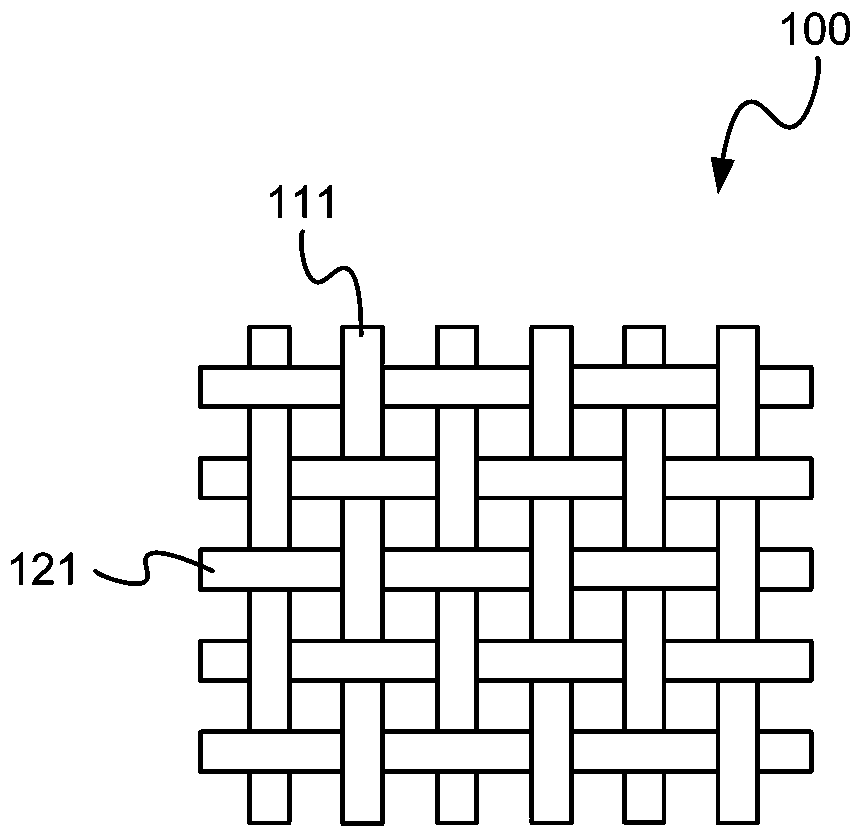

[0029] see Figure 1 ~ Figure 3 Shown are the schematic diagram of the manufacturing process of the elastic fabric of the present invention, the three-dimensional schematic diagram of the double-elastomer core-spun yarn structure of an embodiment of the present invention, and the partial structure schematic diagram of the elastic fabric of an embodiment of the present invention. As shown in the figure: the present invention is a manufacturing method of elastic fabric, which at least comprises the following steps:

[0030] Core yarn raw material step s11: provide a yarn elastic body 1, which is a core yarn made of a first elastic body 11 and a second elastic body 12, wherein the first elastic body 11 is nylon 6 fiber or nylon 66 fiber Either one has a Deny number of 10D-70D, and the second elastic body 12 is an elastic fiber (Spandex) and has a Deny number of 10D-70D.

[0031] Sheath yarn raw material step s12: providing an outer covering fiber layer 2, which is selected from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Danny number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com