Method and device for safely utilizing coal bed gas

A coalbed methane and safe technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of difficult to guarantee catalyst stability, low heat recovery efficiency, low reaction temperature, etc. The effect of large, system pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

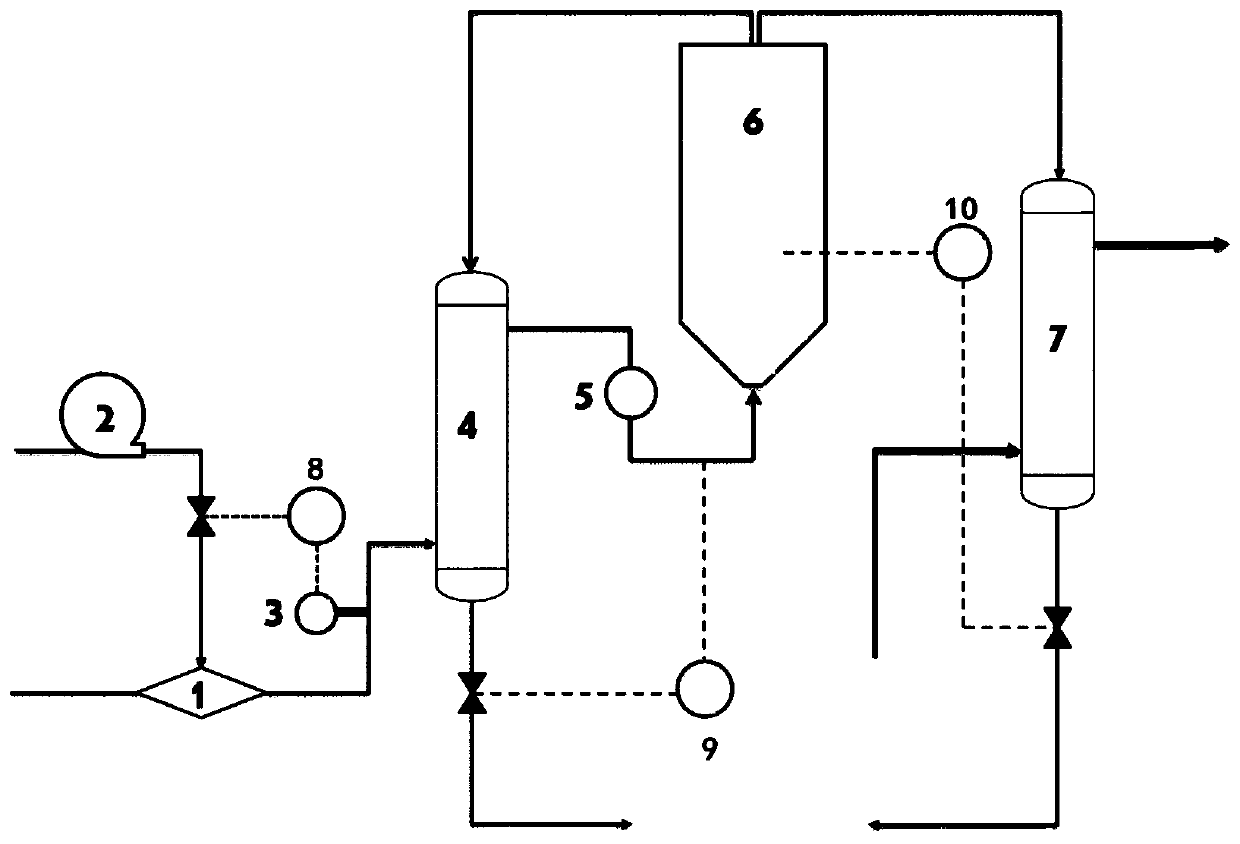

Embodiment 1

[0056] Put into 1000kg catalyst CuO in the fluidized bed reactor 6 0.10 (MnO 2 ) 0.10 (TiO 2 ) 0.10 (γ-Al 2 o 3 ) 0.70 , the particle size of the catalyst is 30-200μm, turn on the induced draft fan 2, and pass 700m into the device 3 Air, catalyst reaction volume space velocity is controlled at 700h -1 , turn on the heater 5, control the inlet temperature of the fluidized bed reactor 6 at 450°C, preheat the catalyst and the fluidized bed; turn off the heater 5, turn off the induced draft fan 2, and feed methane into the gas mixer 1 The volume fraction of coalbed methane is 1.5%, and the amount of coalbed methane added is 500Nm 3 , use the temperature controller 9 to control the export volume of hot gas entering the low-temperature heat exchanger 4 from the fluidized bed reactor 6, and preheat the coalbed gas to 425°C in the low-temperature heat exchanger 4; then gradually feed the coalbed gas into the fluidized bed In the reactor 6, the reaction pressure is 10kPa, and...

Embodiment 2

[0058] Put into 2000kg catalyst CuO in the fluidized bed reactor 6 0.10 (Fe 2 o 3 ) 0.10 (MnO 2 ) 0.10 (TiO 2 ) 0.10 (SiO 2 ) 0.60 , the particle size of the catalyst is 30-250μm, turn on the induced draft fan 2, and pass 1000m into the device 3 Air, catalyst reaction volume space velocity is controlled at 500h -1 , turn on the heater 5 to control the inlet temperature of the fluidized bed reactor 6 at 400°C. The coalbed methane with a methane volume fraction of 2.8% is introduced into the medium, and the amount of coalbed methane added is 1000Nm 3 , the reaction pressure is 15kPa, the methane catalytic combustion reaction occurs between the coalbed gas and the catalyst in the bubbling fluidized bed, and the reaction temperature rises rapidly to 620-650°C; The amount of gas and demineralized water, when the coalbed gas is 8000Nm 3 Finally, the softened water flow rate is 20t / h, and the catalytic combustion reaction space velocity reaches 4000h -1 , to achieve ste...

Embodiment 3

[0060] Put into 5000kg catalyst CuO in the fluidized bed reactor 6 0.10 (Fe 2 o 3 ) 0.15 (MnO 2 ) 0.20 (TiO 2 ) 0.10 (γ-Al 2 o 3 ) 0.55 , the particle size of the catalyst is 50-250μm, turn on the induced draft fan 2, and pass 4000m into the device 3 Air, catalyst reaction volume space velocity is controlled at 800h -1, open heater 5, make the inlet temperature of fluidized bed reactor 6 be controlled at 350 ℃, catalyst and fluidized bed are preheated; Close heater 5, feed methane volume fraction in gas mixer 1 and be 10% coalbed methane, the amount of coalbed methane added is 1000m 3 , the air in the induced draft fan 2 is passed into the gas mixer 1, and the amount of air introduced is 2000m 3 , through the concentration controller 8, the volume fraction of methane in the coalbed gas is controlled at 3.3%; the mixed coalbed gas is passed through the low-temperature heat exchanger 4, and then passed into the fluidized bed reactor 6, and the reaction pressure is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com