A synthesis gas purification method, device and application combining sulfur-tolerant shift and circulating fluidized bed thermal desulfurization

A circulating fluidized bed and synthesis gas purification technology, which is applied in the direction of chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of difficult regeneration of adsorbents, lower thermal efficiency of downstream synthesis gas utilization, and small processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

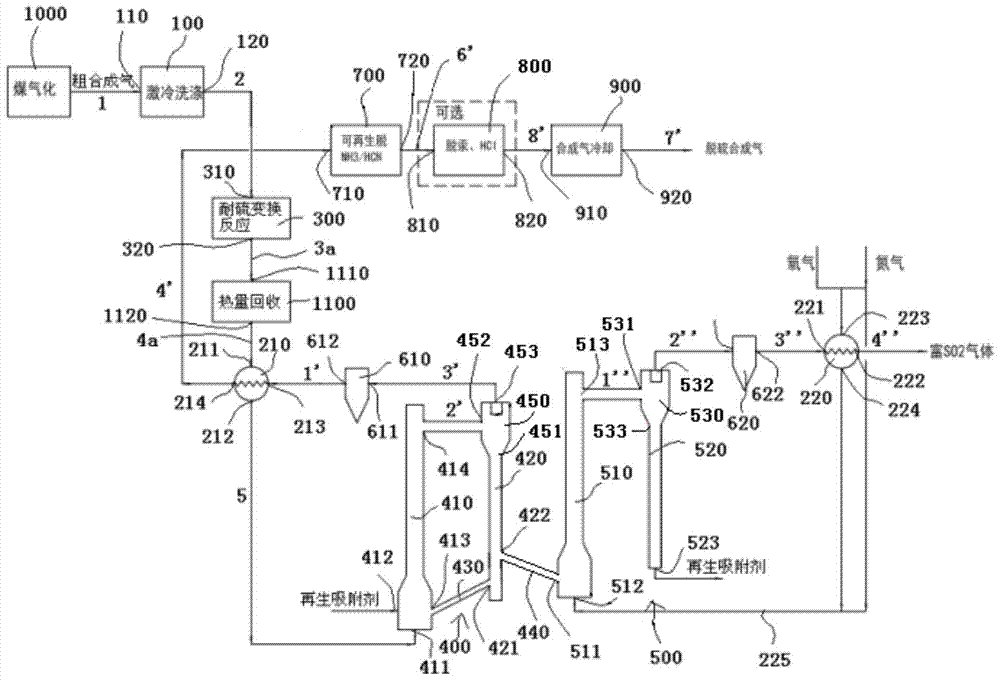

[0158] see figure 1 , the figure shows a synthesis gas purification device combining sulfur-resistant shift and circulating fluidized bed thermal desulfurization, including water quenching washing device 100, heat exchangers 210, 220, heat recovery device 1100, sulfur-resistant shift reaction System 300, adsorption reactor 400 of circulating fluidized bed, regeneration reactor 500 of circulating fluidized bed, filters 610, 620, regenerable NH removal 3 / HCN device 700, mercury and chloride removal device 800, cooling device 900.

[0159] The water quenching and washing device 100 has a crude synthesis gas input port 110 and a crude synthesis gas output port 120. The crude synthesis gas input port 110 of the water quenching and washing device 100 is connected to a coal gasification device 1000 through a crude synthesis gas delivery pipeline 1, The coal gasification device 1000 is a coal-water slurry gasification device, a pulverized coal gasification device or a fixed-bed pulv...

Embodiment 2

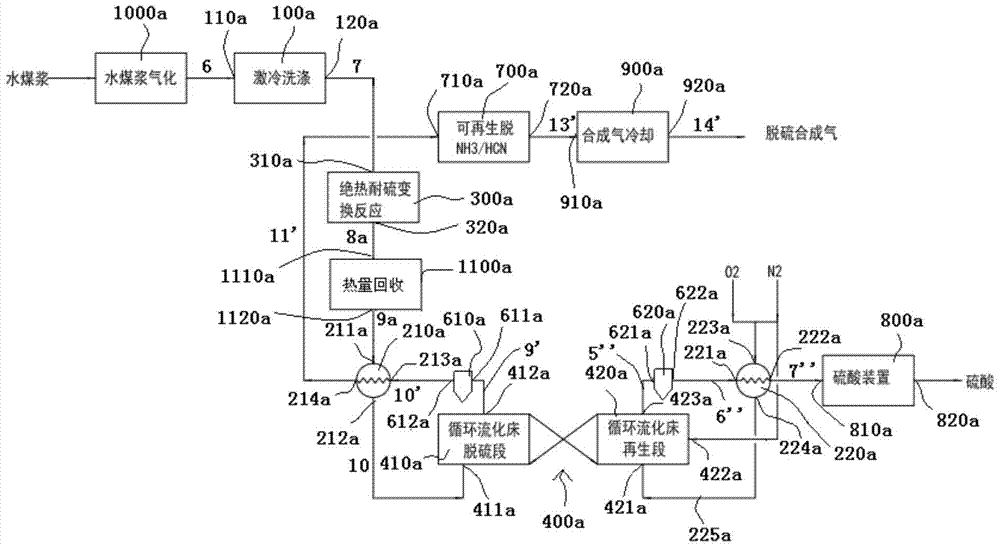

[0197] see figure 2 , shown in the figure is a synthesis gas purification device combining sulfur-resistant conversion and circulating fluidized bed thermal desulfurization, including water quenching washing device 100a, heat exchangers 210a, 220a, heat recovery device 1100a, adiabatic sulfur-resistant conversion Reaction device 300a, circulating fluidized bed 400a, regenerable NH removal 3 / HCN unit 700a, sulfuric acid unit 800a, cooling unit 900a.

[0198] The water quenching and washing device 100a has a crude synthesis gas input port 110a and a crude synthesis gas output port 120a, and the crude synthesis gas input port 110a of the water quenching and washing device 100a is connected to a coal water slurry gasification through a crude synthesis gas delivery pipeline 6 Apparatus 1000a.

[0199] The sulfur-tolerant shift reaction system 300a can adopt the Chinese patent number ZL201210040295.6 applied by the applicant, and the invention name is a radial or axial radial fi...

Embodiment 3

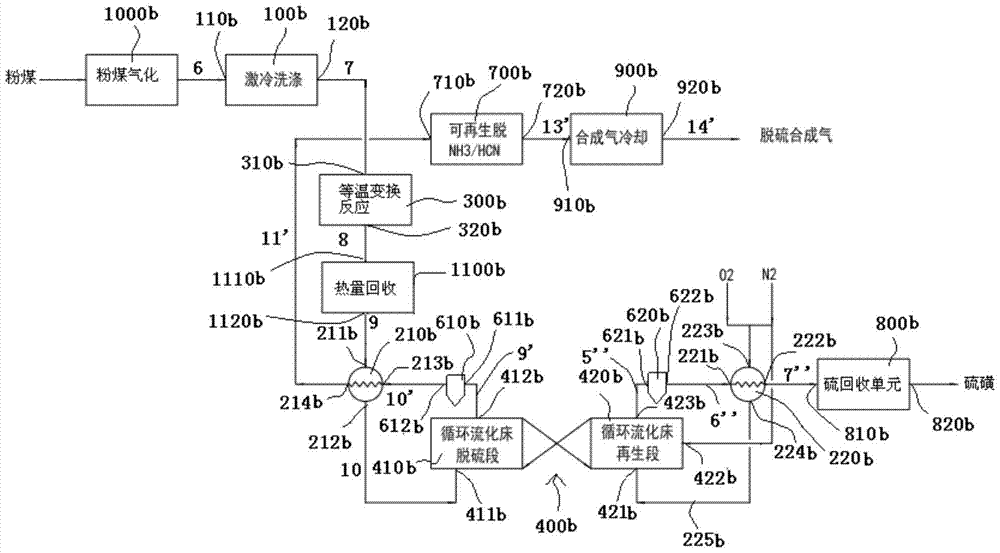

[0218] see image 3 , a synthetic gas purification device combining sulfur-resistant shift and circulating fluidized bed thermal desulfurization shown in the figure, including water quenching washing device 100b, heat exchangers 210b, 220b, heat recovery device 1100b, and isothermal shift reaction system 300b, circulating fluidized bed 400b, regenerable NH removal 3 / HCN unit 700b, sulfur recovery unit 800b, cooling unit 900b.

[0219] The water quenching and washing device 100b has a crude synthesis gas input port 110b and a crude synthesis gas output port 120b, and the crude synthesis gas input port 110b of the water quenching and washing device 100b is connected to a pulverized coal gasification device 1000b through a crude synthesis gas delivery pipeline 6 .

[0220] The isothermal shift reaction system 300b can adopt the Chinese patent number ZL201320176372.0 applied by the applicant, and the invention name is an isothermal fixed-bed reactor in which the catalyst is pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com