A miniature encapsulated ionization gauge

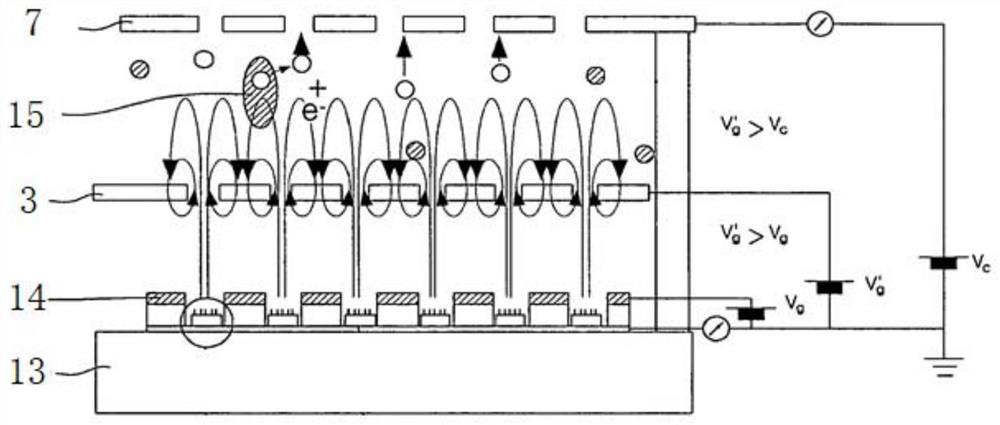

An ionization gauge and encapsulation technology, which is applied in the field of micro-encapsulation ionization gauges, can solve the problems of the inability to extend the measurement lower limit of micro-ionization gauges, limit the characteristics of micro-packages, and electron bombardment to eliminate the high-temperature hot cathode effect and prolong the trajectory. length, to overcome the effect of low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0028] According to the working principle of the ionization gauge, improving the sensitivity is a practical and feasible technical way to extend this kind of miniature package ionization gauge. Therefore, according to the theoretical calculation formula of the sensitivity S, it can be known that

[0029]

[0030] Among them, σ represents the ionization cross section, k is the Boltzmann constant, T is the Kelvin temperature, and L is the length of the trajectory of electrons in the ionization region. Therefore, extending L is an effective technical approach to improve the sensitivity of the miniature ionization gauge.

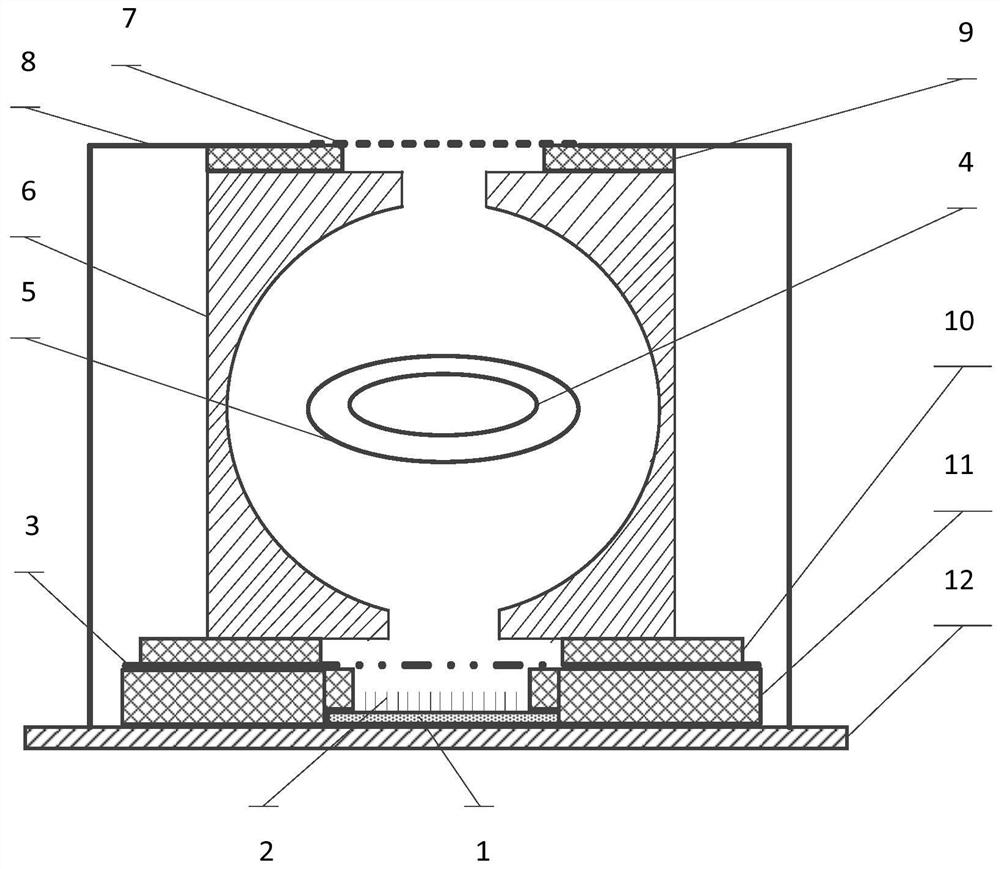

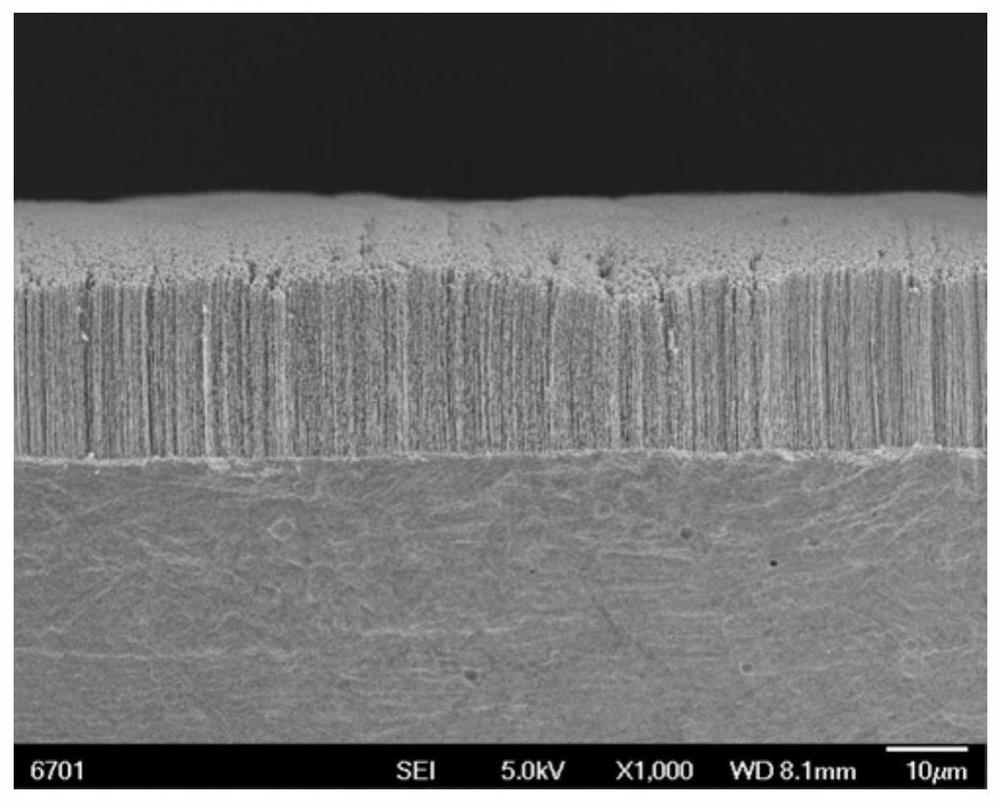

[0031] This embodiment provides a kind of miniaturized encapsulation type ionization gauge, such as figure 2 As shown, the ionization gauge includes a carbon nanotube cathode substrate 1, a carbon nanotube array 2, a gate electrode 3, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com