Tab molding mechanism, molding method and tab molding equipment

A molding mechanism and lug technology, applied in structural parts, sustainable manufacturing/processing, electrical components, etc., can solve problems such as insufficient energy utilization, uneven temperature distribution, and low production efficiency, and achieve uniform current distribution and heating Good effect, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

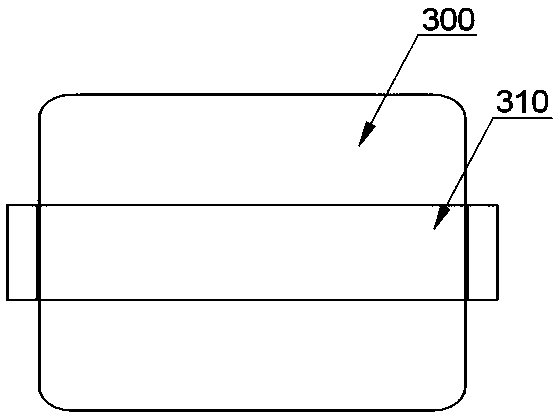

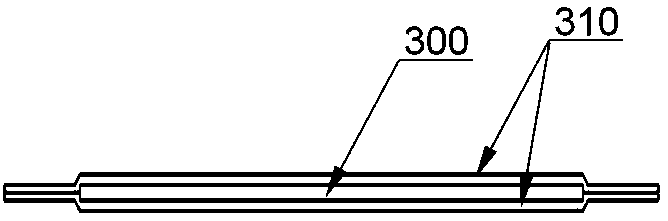

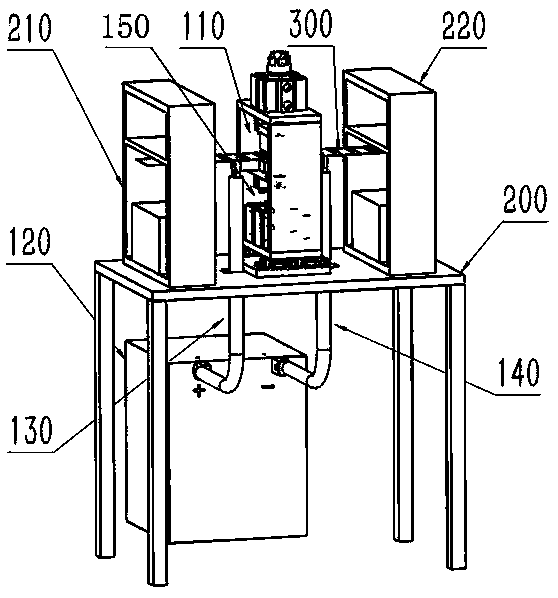

[0041] An embodiment of the present invention provides a tab forming mechanism for figure 1 , figure 2 The thermal compounding process of the metal strip 300 and the tab glue 310 is shown, wherein the metal strip 300 is stretched into a strip shape from the metal strip 300 rolled in the previous process 210 by self-heating, and several pairs of the tab glue 310 and the metal The length direction of the strip 300 is vertical and arranged on the upper and lower surfaces of the metal strip 300 at intervals, and the tab glue 310 on the same side of the metal strip 300 is attached to each other at the position extending out of the metal strip 300 ( figure 2 , Figure 6 shown in ). see Figure 3-Figure 6 , the tab forming mechanism includes a DC power supply 120, a pressing mechanism 110 formed above the metal strip 300, and a conductive mechanism 150 formed below the metal strip 300, and the conductive mechanism 150 includes a first electrode 8 and a second electrode 9 The fi...

Embodiment 2

[0056] Embodiment 2 of the present invention discloses the tab forming method of the tab forming mechanism described in Embodiment 1, which is used in the thermal compounding process of metal strip 300 and tab glue 310, including the following steps:

[0057] Step S1: The pressed metal strip 300 and the ear glue 310 are threaded between the conductive mechanism 150 and the pressing mechanism 110, and the first electrode 8 and the second electrode 9 are aligned on both sides of the ear glue 310, corresponding to The metal strip 300 is not provided with the position setting of the ear glue 310;

[0058]Step S2: the first cylinder 5 operates, the first electrode 8 and the second electrode 9 rise and contact the metal strip 300;

[0059] Step S3: the second air cylinder 15 operates, the first pressing block 17 and the second pressing block 18 descend to press the metal strip 300 onto the first electrode 8 and the second electrode 9;

[0060] Step S4: Turn on the DC power supply 1...

Embodiment 3

[0067] Embodiment 3 of the present invention discloses a tab forming device, which includes the tab forming mechanism described in Embodiment 1. The tab forming equipment also includes a tab forming mechanism and a cutting mechanism after thermally laminating the metal strip 300 and the tab glue 310 . In the embodiment of the present invention, a plurality of lugs 310 on the metal strip 300 are thermally compounded on the metal strip 300, and then cutting and other processes are performed to effectively improve product production efficiency and product qualification rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com