A kind of preparation method of carbon nitride fluffy microsphere with high catalytic activity

A high catalytic activity, carbon nitride technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of rapid acquisition and large-scale application of zero-dimensional carbon nitride The carbon nitride size is small, the preparation process is complicated, etc., and the effect of high practical value, inhibition of agglomeration, and simple synthesis process is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Put 5 g of melamine into 70 mL of sulfuric acid solution with a concentration of 0.5 mol / L, ultrasonically disperse it for 30 min, then transfer it to a 100 mL hydrothermal kettle and heat it at 180°C for 8 h, and cool it down to room temperature naturally; collect the white precipitate by suction filtration and use deionized Wash with water three times, dry overnight at 80°C, and grind into powder, which is the precursor; put the precursor into a ceramic crucible, cover the crucible and place it in the center of the muffle furnace cavity, and slowly heat up at a rate of 2°C / min Raise the temperature to 550°C and keep it warm for 4 hours, then open the furnace door and cool down to room temperature naturally to obtain fluffy carbon nitride microspheres.

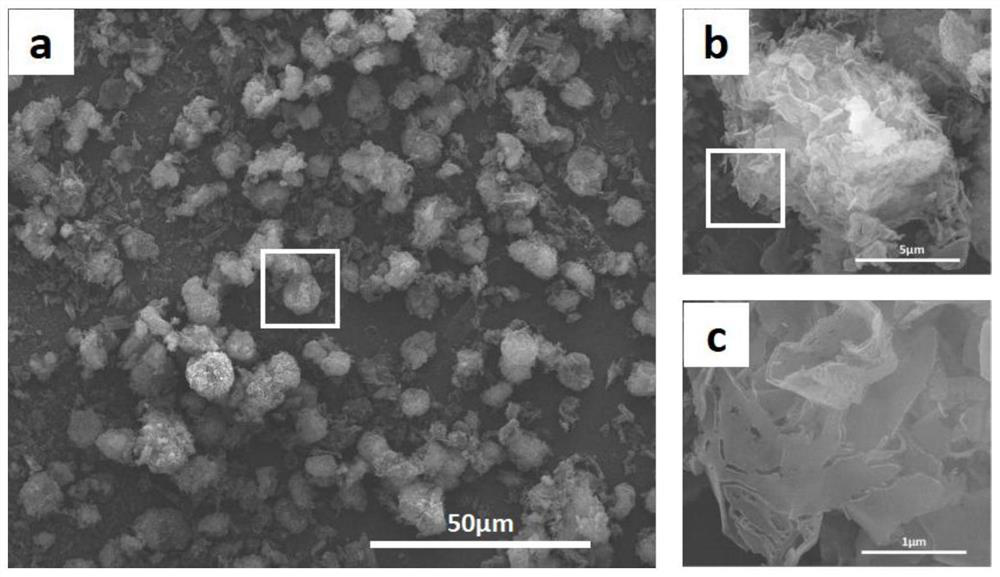

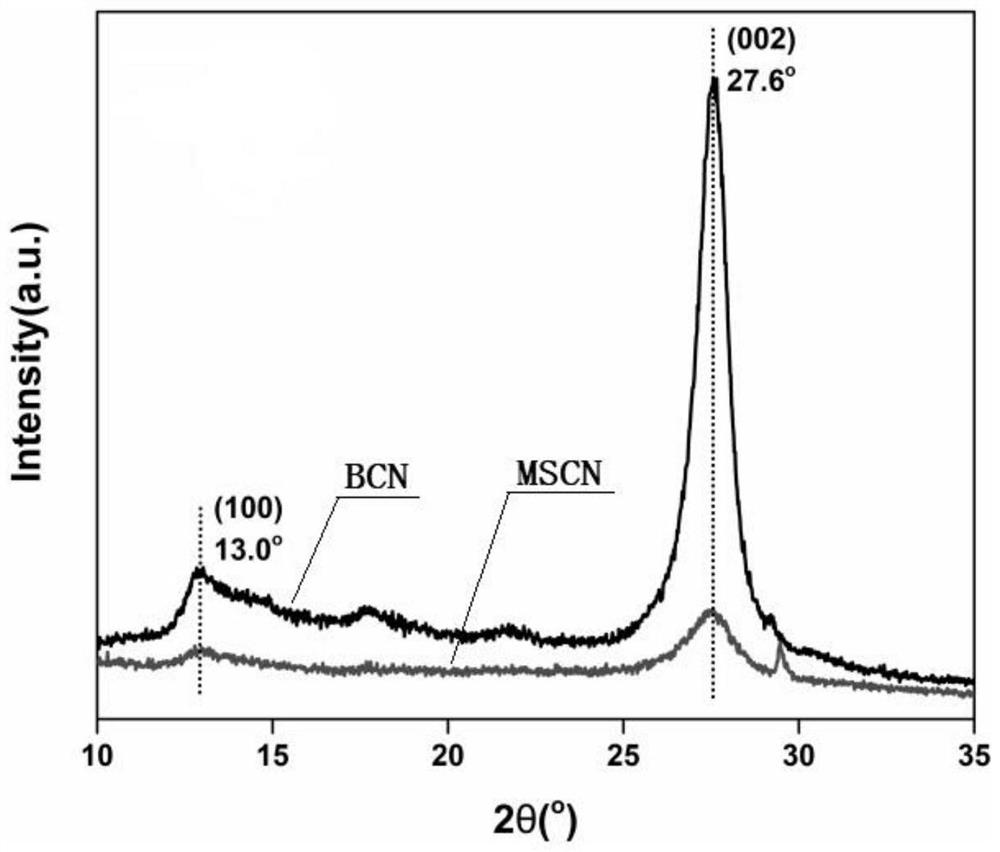

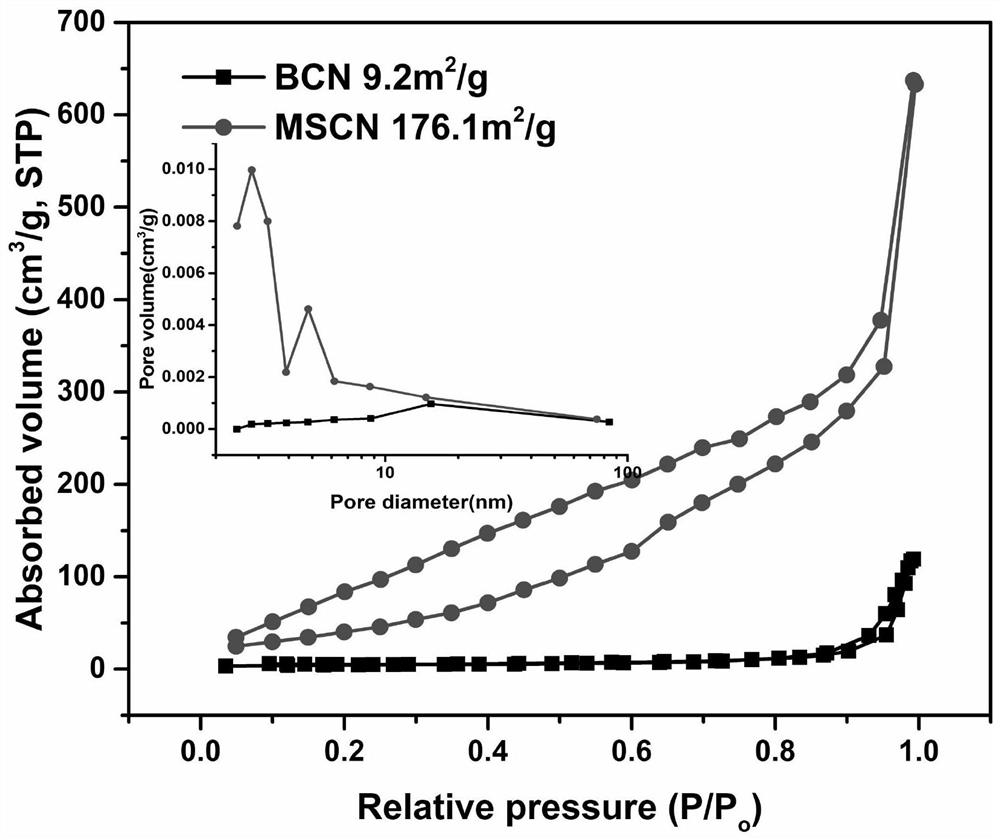

[0028] figure 1 SEM images of carbon nitride fluffy microspheres under different magnifications, figure 1 a It can be seen that the size of the microspheres is relatively uniform, showing a fluffy spherical or ellipso...

Embodiment 2

[0033] Put 5 g of melamine into 70 mL of sulfuric acid solution with a concentration of 1.0 mol / L, ultrasonically disperse it for 30 min, then transfer it to a 100 mL hydrothermal kettle and heat it at 180°C for 8 h, then cool it down to room temperature naturally; collect the white precipitate by suction filtration and use deionized Wash with water three times, dry overnight at 60°C, and grind into powder, which is the precursor; put the precursor into a ceramic crucible, cover the crucible and place it in the center of the muffle furnace cavity, and slowly heat up at a rate of 2°C / min Raise the temperature to 550°C and keep it warm for 4 hours, then open the furnace door and cool down to room temperature naturally to obtain fluffy carbon nitride microspheres. The diameter of the microsphere is about 8 μm, and the specific surface area is 203.6m 2 / g, the photocatalytic first-order kinetic constant is 0.614min -1 .

Embodiment 3

[0035] Put 5 g of melamine into 70 mL of sulfuric acid solution with a concentration of 2.0 mol / L, ultrasonically disperse it for 30 min, then transfer it to a 100 mL hydrothermal kettle and heat it at 120°C for 8 h, and cool it to room temperature naturally; collect the white precipitate by suction filtration and use deionized Wash with water three times, dry overnight at 40°C, and grind into powder, which is the precursor; put the precursor into a ceramic crucible, cover the crucible and place it in the center of the muffle furnace cavity, and slowly heat up at a rate of 2°C / min Raise the temperature to 550°C and keep it warm for 4 hours, then open the furnace door and cool down to room temperature naturally to obtain fluffy carbon nitride microspheres. The diameter of the microsphere is about 14μm, and the specific surface area is 152.3m 2 / g, the photocatalytic first-order kinetic constant is 0.457min -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com