Styrene-maleic anhydride structure containing and graft-modified water-based pigment dispersant and preparation method thereof

A technology of grafting modifier and maleic anhydride, which is applied in the direction of pigment slurry, etc., can solve the problems of insufficient anchoring ability and poor steric hindrance, and achieve the effects of large steric hindrance, strong anchoring ability and strong tinting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

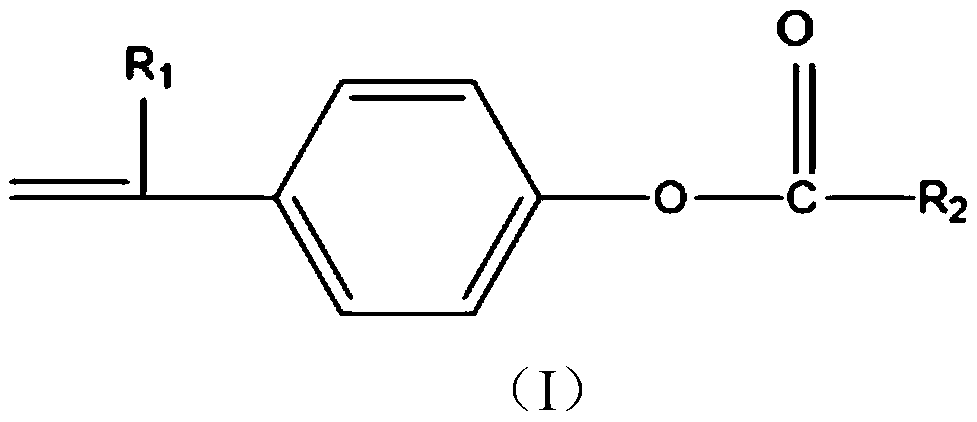

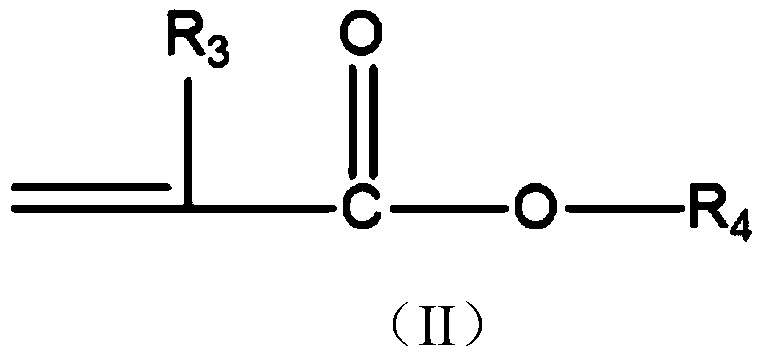

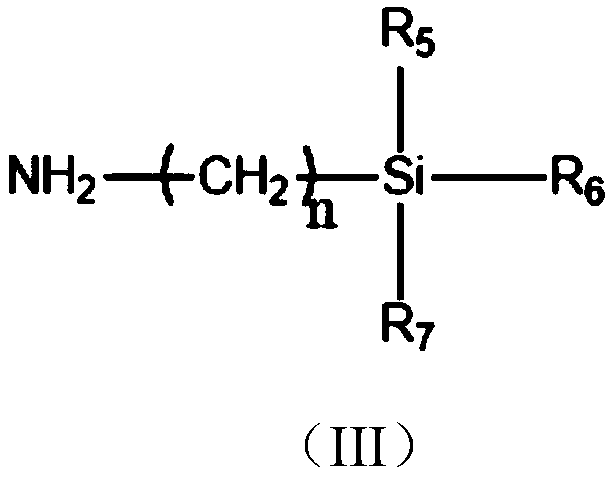

Method used

Image

Examples

specific Embodiment 1

[0044] Mix 27 parts of styrene, 32 parts of styrene derivative A1, 18 parts of maleic anhydride, 23 parts of acrylic acid derivative B1 and 300 parts of 1,4-dioxane into a mixed solution and place it in the reactor In, nitrogen gas was introduced for 25 minutes and the temperature was controlled at 85°C, and a mixture consisting of 8 parts of azobisisobutyronitrile, 4 parts of dodecanethiol and 50 parts of 1,4-dioxane was slowly added dropwise to In the reactor, the dropping time is 3 hours, and the reaction is continued for 2 hours after the dropping; continue to add 10.8 parts of 3-aminopropyltrimethoxysilane and 4 parts of p-toluenesulfonic acid, the reaction temperature is 85 °C, and the reaction time is 4 Hours, after the reaction is over, remove 1,4-dioxane and cool to room temperature to obtain a water-based pigment dispersant containing styrene-maleic anhydride and graft-modified.

specific Embodiment 2

[0046] 15 parts of styrene, 40 parts of styrene derivative A2, 25 parts of maleic anhydride, 20 parts of acrylic acid derivative B2 four monomers and 300 parts of cyclohexane are made into a mixed solution and placed in a reactor, and nitrogen gas is introduced For 15 minutes, the temperature was controlled at 100°C, and the mixture composed of 8 parts of benzoyl peroxide, 4 parts of α-methylstyrene linear dimer and 50 parts of cyclohexane was slowly added dropwise to the reactor, and the The time is 2 hours, continue to react for 3 hours after the dropwise addition; continue to add 10.8 parts of 3-aminopropyltriethoxysilane and 4 parts of aluminum trichloride, the reaction temperature is 100 ° C, the reaction time is 2 hours, the reaction ends Afterwards, the cyclohexane was removed, cooled to room temperature, and a water-based pigment dispersant containing styrene-maleic anhydride and graft-modified was obtained.

specific Embodiment 3

[0048] 21 parts of styrene, 28 parts of styrene derivative A3, 13 parts of maleic anhydride, 38 parts of acrylic acid derivative B3 four monomers and 300 parts of tetrahydrofuran were formulated into a mixed solution and placed in a reactor, and nitrogen gas was introduced for 30 minutes. The temperature is controlled at 70°C, and the mixed solution consisting of 8 parts of dicumyl peroxide, 4 parts of dodecanethiol and 50 parts of tetrahydrofuran is slowly added dropwise to the reactor, and the dropping time is 4 hours. Continue to react for 1 hour; continue to add 10.8 parts of 3-aminopropyldimethylmethoxysilane and 4 parts of triethylamine, the reaction temperature is 70°C, and the reaction time is 6 hours. After the reaction, remove tetrahydrofuran and cool to room temperature. A water-based pigment dispersant containing styrene-maleic anhydride and graft-modified is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com