Light-cured liquid resin for three-dimensional molding

A liquid resin, three-dimensional technology, applied in the field of materials, can solve problems such as large shrinkage, limiting the development of 3D printing accuracy and applications, and smaller gaps between molecules, achieving reduced shrinkage, improved mechanical strength, and wide application performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

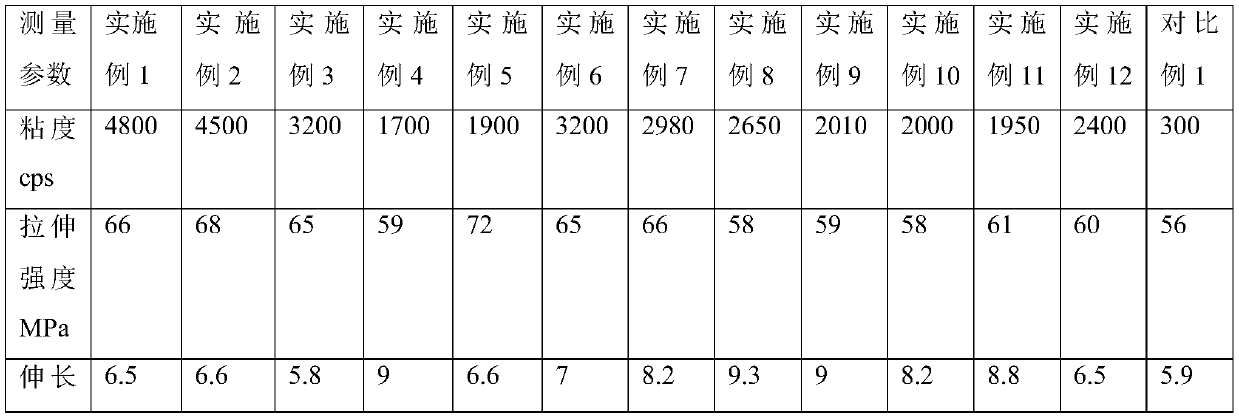

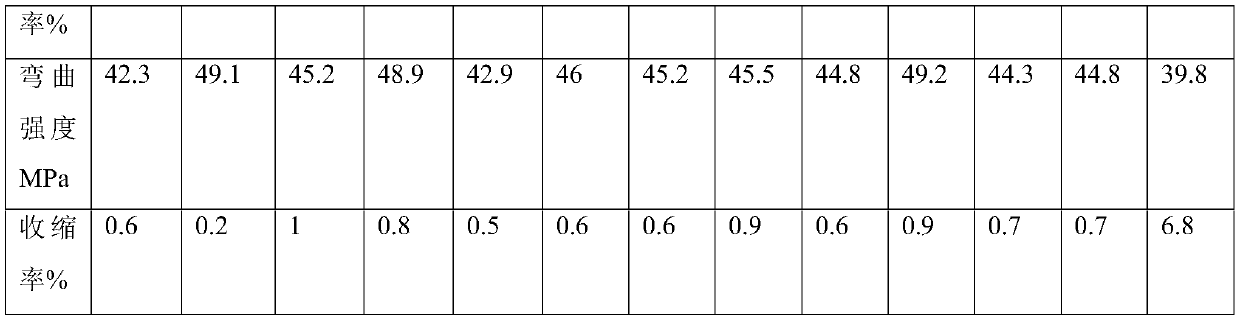

Examples

Embodiment 1

[0019] Put each component material into the material barrel according to the following mass percentage ratio and mix:

[0020] The first urethane acrylate, with a content of 70%, is an aliphatic urethane acrylate with a functionality of 2 and a number average molecular weight Mn of 3000g / mol;

[0021] 10% of the second urethane acrylate, which is an aromatic urethane acrylate with a functionality of 3 and a number average molecular weight Mn of molecular weight 100000g / mol;

[0022] Crosslinker monomer, DPHA 1%,

[0023] Reactive diluent, ACMO 10%;

[0024] Tackifying resin SIS 5%, its molecular weight Mw is 100000g / mol;

[0025] Photoinitiator, TPO 5%.

[0026] Then, it was fully stirred under the condition of avoiding light, and stood still for 24 hours to finally obtain a photocurable liquid resin for three-dimensional stereoforming.

Embodiment 2

[0028] Put each component material into the material barrel according to the following mass percentage ratio and mix:

[0029] 10% of the first urethane acrylate is an aliphatic urethane acrylate with a functionality of 2 and a number average molecular weight Mn of 100000g / mol,

[0030] The second urethane acrylate 50%, which is an aromatic urethane acrylate with a functionality of 6 and a number average molecular weight Mn of 3000g / mol,

[0031] Crosslinker monomer DPHA, 10%,

[0032] Reactive diluents, including: ACMO 20%, IBOA 10%,

[0033] Photoinitiators, including: TPO 0.5%, EDB 0.5%.

[0034] Then, it was fully stirred under the condition of avoiding light, and stood still for 24 hours to finally obtain a photocurable liquid resin for three-dimensional stereoforming.

Embodiment 3

[0036] Put each component material into the material barrel according to the following mass percentage ratio and mix:

[0037] The first urethane acrylate 30%, which is an aliphatic urethane acrylate with a functionality of 2 and a number average molecular weight Mn of 5000 g / mol,

[0038] The second urethane acrylate 10%, it is aliphatic urethane acrylate, functionality is 5, number average molecular weight Mn is 8000g / mol,

[0039] Crosslinker Monomer TMPTA 40%,

[0040] Reactive diluent HEMA 14.75%,

[0041] Photoinitiators, including: TPO 5%, 819 0.25%.

[0042] Then, it was fully stirred under the condition of avoiding light, and stood still for 24 hours to finally obtain a photocurable liquid resin for three-dimensional stereoforming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com