Preparation method of low-temperature conductance coefficient crosslinked polyethylene insulating material

A technology of cross-linked polyethylene and low-density polyethylene, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of difficult industrial application of nanocomposite insulating materials and difficulty in ensuring the dispersion of nanoparticles, and achieve improvement Electric field distribution, improvement of conductance-temperature characteristics, effects of reducing by-products and impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through specific embodiments and accompanying drawings. The embodiments of the present invention are for better understanding of the present invention by those skilled in the art, and do not limit the present invention in any way.

[0017] First, put the low-density polyethylene (LDPE) in a drying oven, set the temperature at 80°C, and dry for 48 hours to remove the moisture that may exist in the LDPE and ensure that the LDPE is clean and dry.

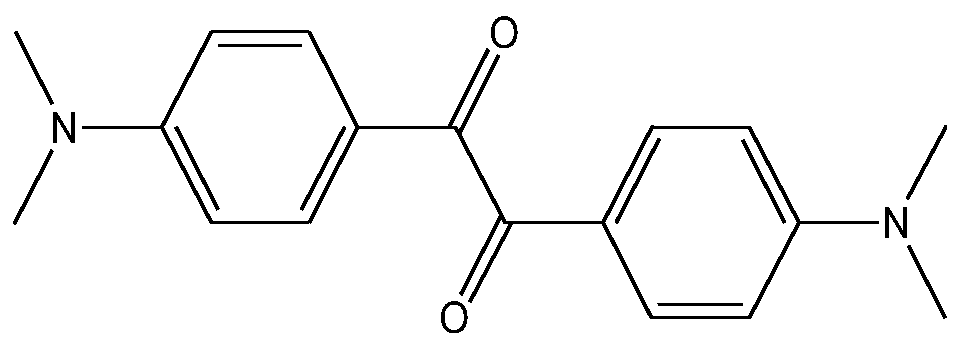

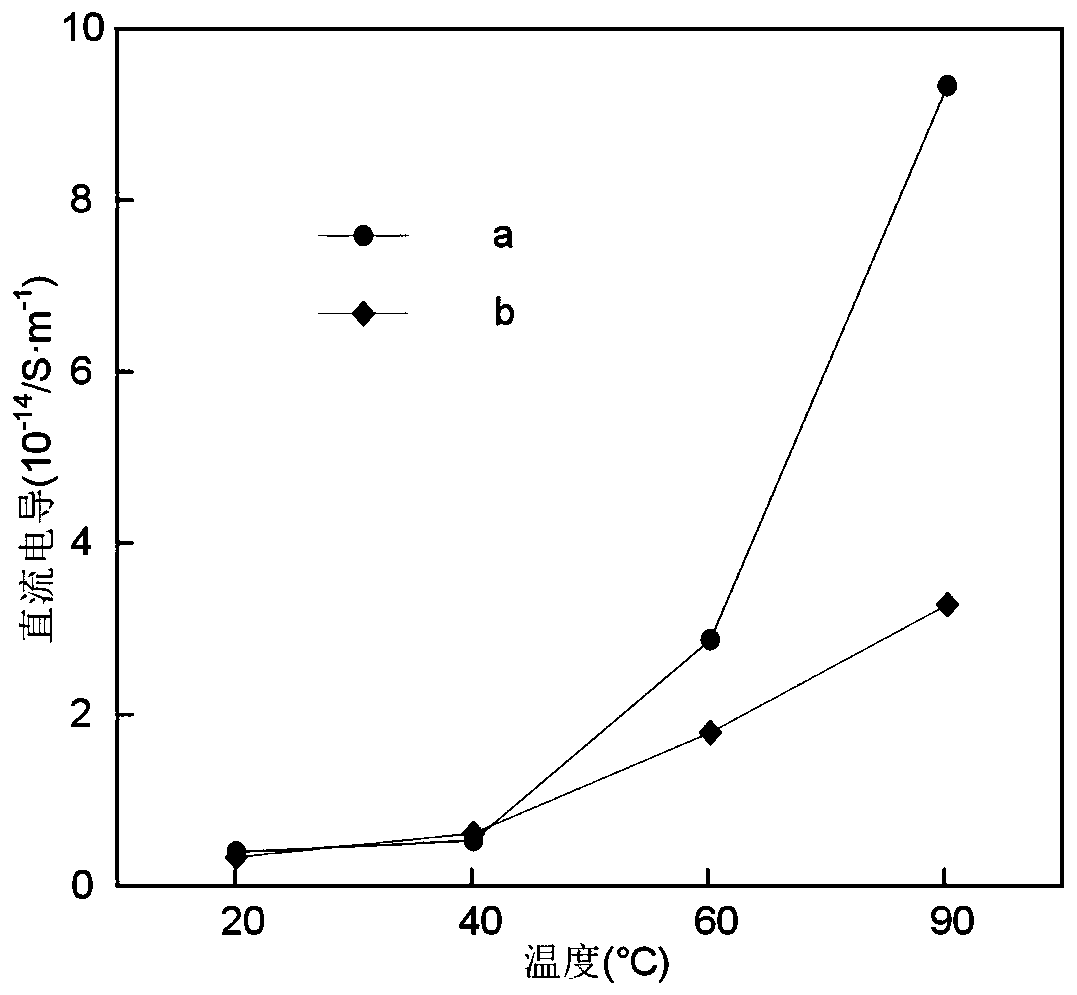

[0018] Next, add 0.1g of antioxidant 1010, 2g of dicumyl peroxide (DCP) and 0.3g of 4,4'-bisdimethylaminobenzil into a three-necked bottle, add xylene solvent, and stir ultrasonically for 30min to make it Fully dissolve and disperse; add 100g LDPE particles to the mixed solution, and stir in an oil bath at 110°C for 3 hours to obtain a LDPE mixed solution; pour the mixed solution into a glass mold, and dry it in an oven at a temperature of 70°C to remove xylene to obtain a L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com