Two-component room temperature vulcanized fluorosilicone sealant and preparation method thereof

A room temperature vulcanization, two-component technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc. Long time, difficult to control the surface drying time of fluorosilicone sealant, etc., to achieve the effect of reducing material cost, fast curing, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 1 part of tetramethyldivinyldisilazane and 1 part of KH550 to 100 parts of fumed silica, stir and react in a planetary mixer at 95°C for 2h, then take it out and dehydrate at 105°C for 2h, and dry it for later use.

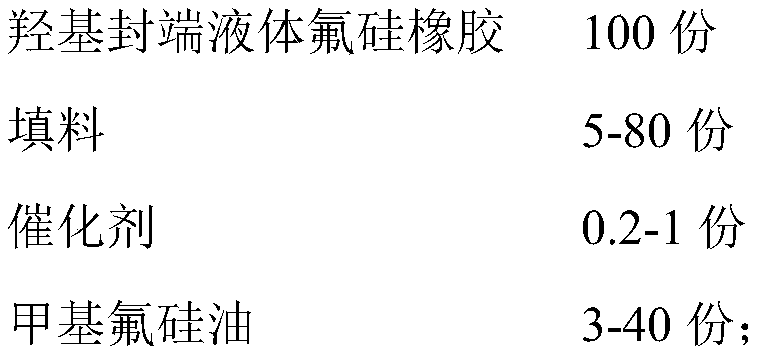

[0032] Add 100 parts of hydroxyl-terminated liquid fluorosilicone rubber into the high-speed disperser, then add 20 parts of treated fumed silica, mix well, add 20 parts of precipitated calcium carbonate, and then add 0.5 parts of platinum and silane complexes , 8 parts of methyl fluorosilicone oil, stirred for 20 minutes, after rough mixing, mixed three times with a three-roller mill, then added to a planetary mixer, and vacuumed at 60°C until the mixture was uniform and free of bubbles, and discharged after 30 minutes, to obtain Component A, kept sealed under nitrogen gas for later use.

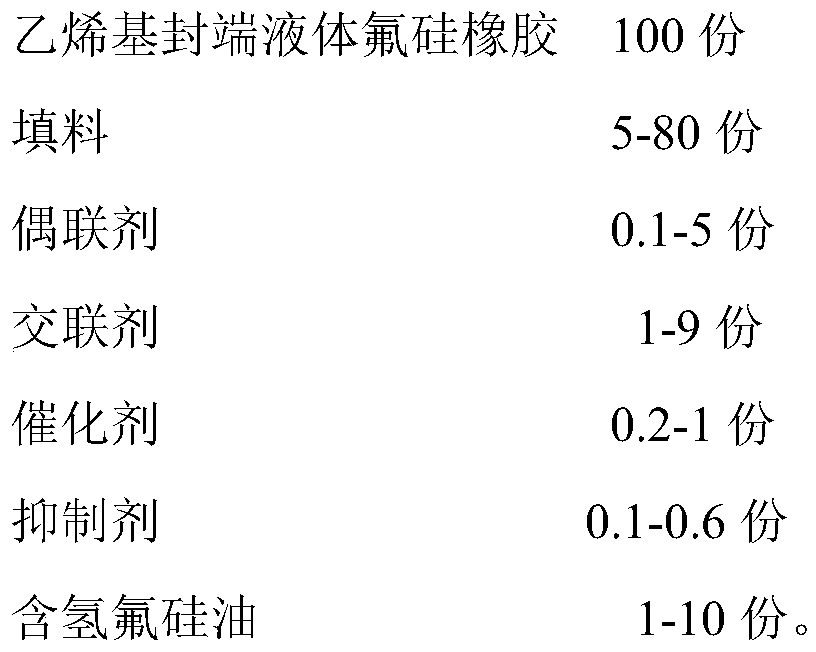

[0033] Add 100 parts of vinyl-terminated liquid fluorosilicone rubber into the high-speed disperser, then add 20 parts of treated fumed silica, mix well, add 10 part...

Embodiment 2

[0036] Add 1 part of tetramethyldihexenyldisilazane and 2 parts of KH550 to 100 parts of diatomaceous earth, stir and react in a planetary mixer at 125°C for 3 hours, then take it out and dehydrate at 105°C for 3 hours, and dry it for later use.

[0037] Add 100 parts of hydroxyl-terminated liquid fluorosilicone rubber into the high-speed disperser, then add 20 parts of diatomaceous earth, then add 0.5 parts of platinum and silane complexes, 40 parts of methyl fluorosilicone oil, and stir for 20 minutes. After rough mixing, use a three-roller mill to mix three times, then add it to a planetary mixer, and vacuumize at 60°C until the mixture is uniform and free of air bubbles. After 30 minutes, the material is discharged to obtain component A, which is stored in nitrogen and sealed for later use.

[0038] Add 100 parts of vinyl-terminated liquid fluorosilicone rubber into the high-speed disperser, then add 20 parts of diatomite, mix well, add 10 parts of titanium dioxide, and the...

Embodiment 3

[0041] Add 3 parts of tetramethyldipropenyldisilazane and 1 part of KH570 to 100 parts of titanium dioxide, stir and react in a planetary mixer at 110°C for 2h, then take it out and dehydrate at 105°C for 2h, and dry it for later use.

[0042] Add 100 parts of hydroxyl-terminated liquid fluorosilicone rubber into the high-speed disperser, then add 20 parts of treated titanium dioxide, mix well and add 20 parts of precipitated calcium carbonate, then add 0.5 parts of platinum and silane complexes, 3 parts Methyl fluorosilicone oil, stirred for 20 minutes, after rough mixing, mixed three times with a three-roller mill, then added to a planetary mixer, and vacuumed at 60°C until the mixture was uniform and free of air bubbles, and discharged after 30 minutes to obtain component A , kept sealed under nitrogen gas for later use.

[0043]Add 100 parts of vinyl-terminated liquid fluorosilicone rubber into the high-speed disperser, then add 20 parts of treated titanium dioxide, mix we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com