A kind of free-cutting steel for automobile synchronizer and preparation method thereof

A free-cutting steel and synchronizer technology, applied in the field of free-cutting steel, can solve the problems of high surface quality, unfavorable to satisfy high sulfur content, high carburization and machinability at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

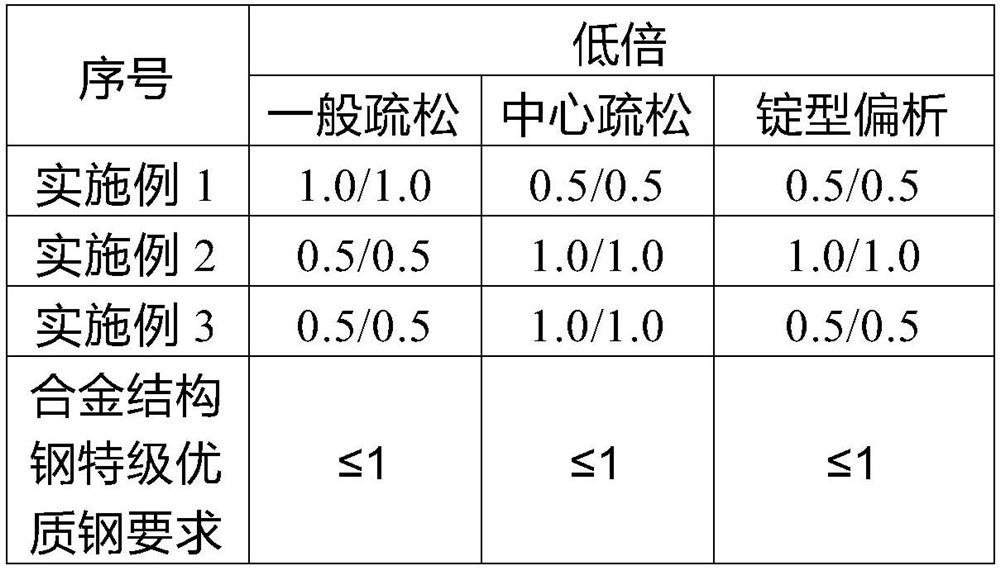

Examples

Embodiment Construction

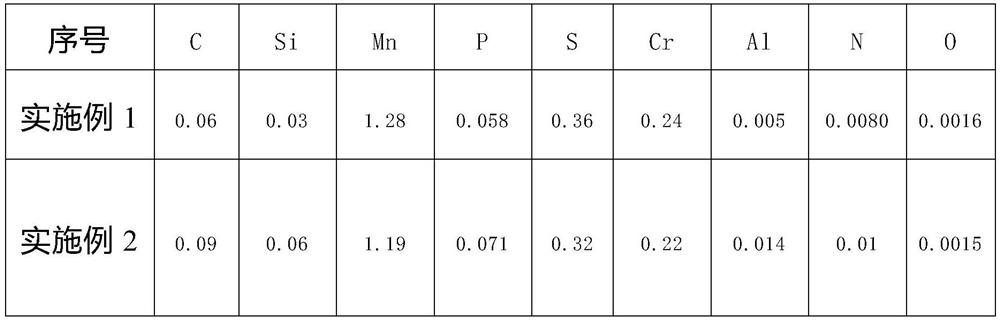

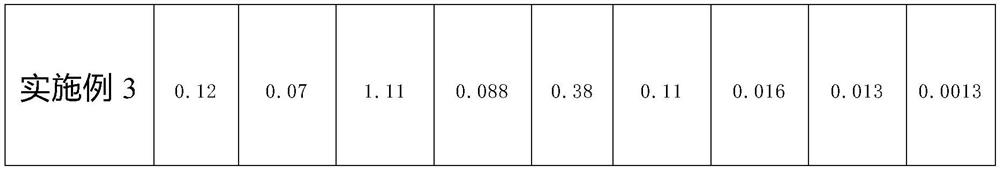

[0031] The steel for free-cutting automobile synchronizer of the present invention, by weight percentage, comprises:

[0032] C: 0.06% to 0.12%, Mn: 1.00% to 1.30%, Si: ≤0.08%, Cr: 0.10% to 0.40%, P: 0.050% to 0.100%, S: 0.32% to 0.40%, N: 0.006% ~0.015%, Al: 0~0.040%, [O]≤0.0020%, the balance is iron and unavoidable impurity elements.

[0033] According to the specific performance requirements of the product, the internal control range of each element is: C: target value ±0.01%, Mn alloy element: target value ±0.04%, the residual harmful elements are as low as possible, and the Mn / S ratio is controlled to be ≥3.

[0034] in:

[0035] C: It can increase the content of pearlite in the structure in steel, and it is the main element to improve the strength of steel. However, if the C content is too high, the cutting resistance will increase and the machinability will be deteriorated. Controlling the C content at 0.06% to 0.12% can ensure that the steel of the invention can not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com