Energy-saving optimal control method and system of engine electric control silicone oil fan

An optimized control and engine technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the influence of engine radiator temperature fluctuations, increase the service life and performance of internal combustion engines, and do not consider the external environment adaptive adjustment controller parameters and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

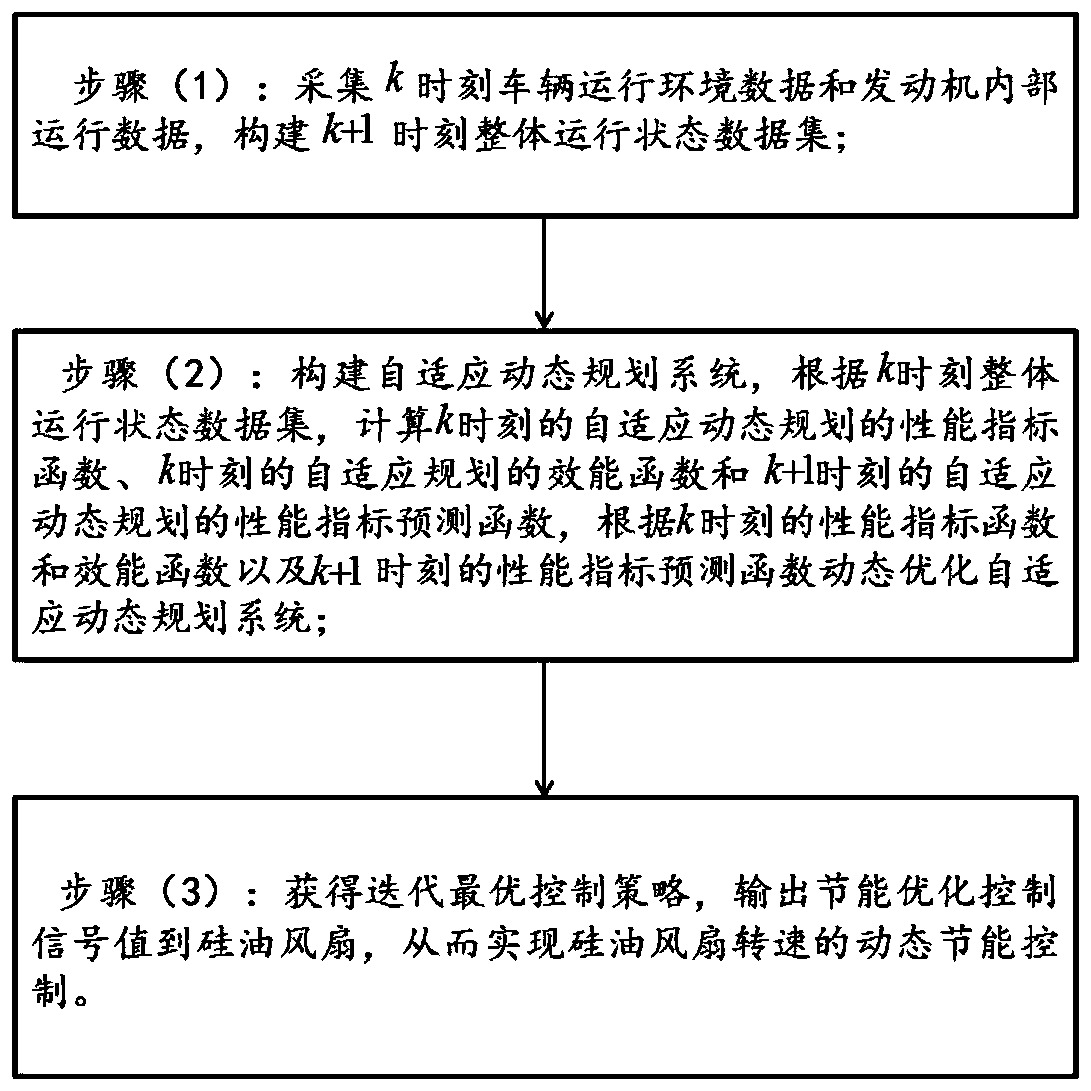

[0062] like figure 1 and 2 As mentioned above, on the one hand, Embodiment 1 of the present disclosure provides an energy-saving optimization control method for an engine electronically controlled silicon oil fan, and the steps are as follows:

[0063] (1) Collect vehicle operating environment data and engine internal operating data at time k, and construct an overall operating state data set at time k;

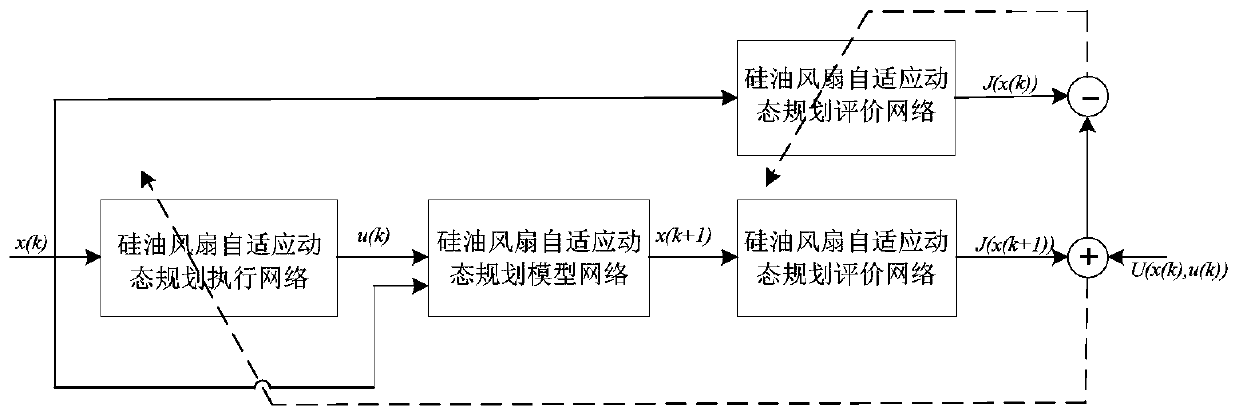

[0064] (2) Build an adaptive dynamic programming system, and calculate the performance index function of adaptive dynamic programming at k time, the performance function of adaptive planning at k time and the adaptive dynamics at k+1 time according to the overall operating state data set at time k The planned performance index prediction function dynamically optimizes the adaptive dynamic programming system according to the performance index function and efficiency function at time k and the performance index prediction function at time k+1;

[0065] (3) An iterative optima...

Embodiment 2

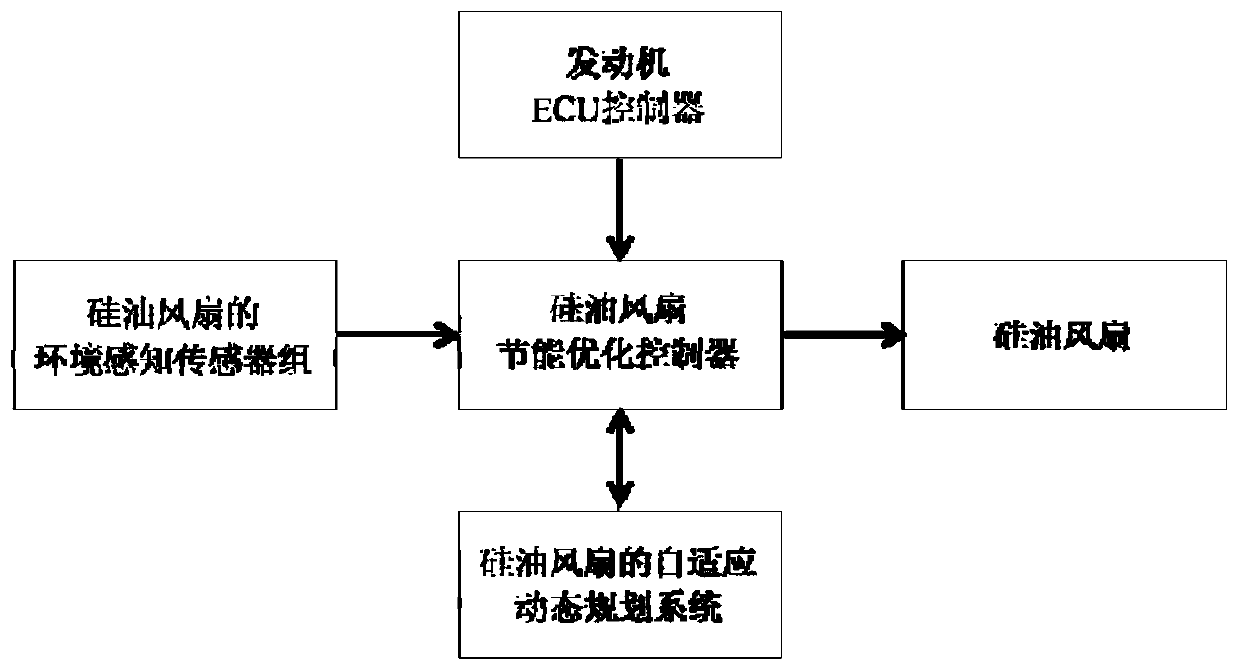

[0111] like figure 2 and 3 As shown, Embodiment 2 of the present disclosure provides an energy-saving optimization control system for an engine electronically controlled silicon oil fan, including a sensor module, an engine electronic control module, an energy-saving optimization control module, and a silicon oil fan;

[0112] The sensor module is connected to the energy-saving optimization control module, and the sensor module is an environment-aware sensor group of a silicone oil fan including a plurality of environment-aware sensors, which is used to collect environmental data and transmit it to the energy-saving optimization control module;

[0113] The vehicle environment perception sensor group mainly includes the following sensors:

[0114] (1) Temperature sensor outside the vehicle: used to measure the temperature value of the environment outside the vehicle;

[0115] (2) Humidity sensor outside the vehicle: used to measure the humidity value of the environment outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com