Superhigh-pressure temperature sensor

A temperature sensor and ultra-high pressure technology, applied in thermometers, thermometer parts, instruments, etc., can solve the problems of difficulty in reflecting the changing trend of the temperature effect of rapid charging and discharging, long response time of temperature measurement, and large wall thickness, etc., to achieve thermal The effect of small capacity, strong timeliness and fast heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

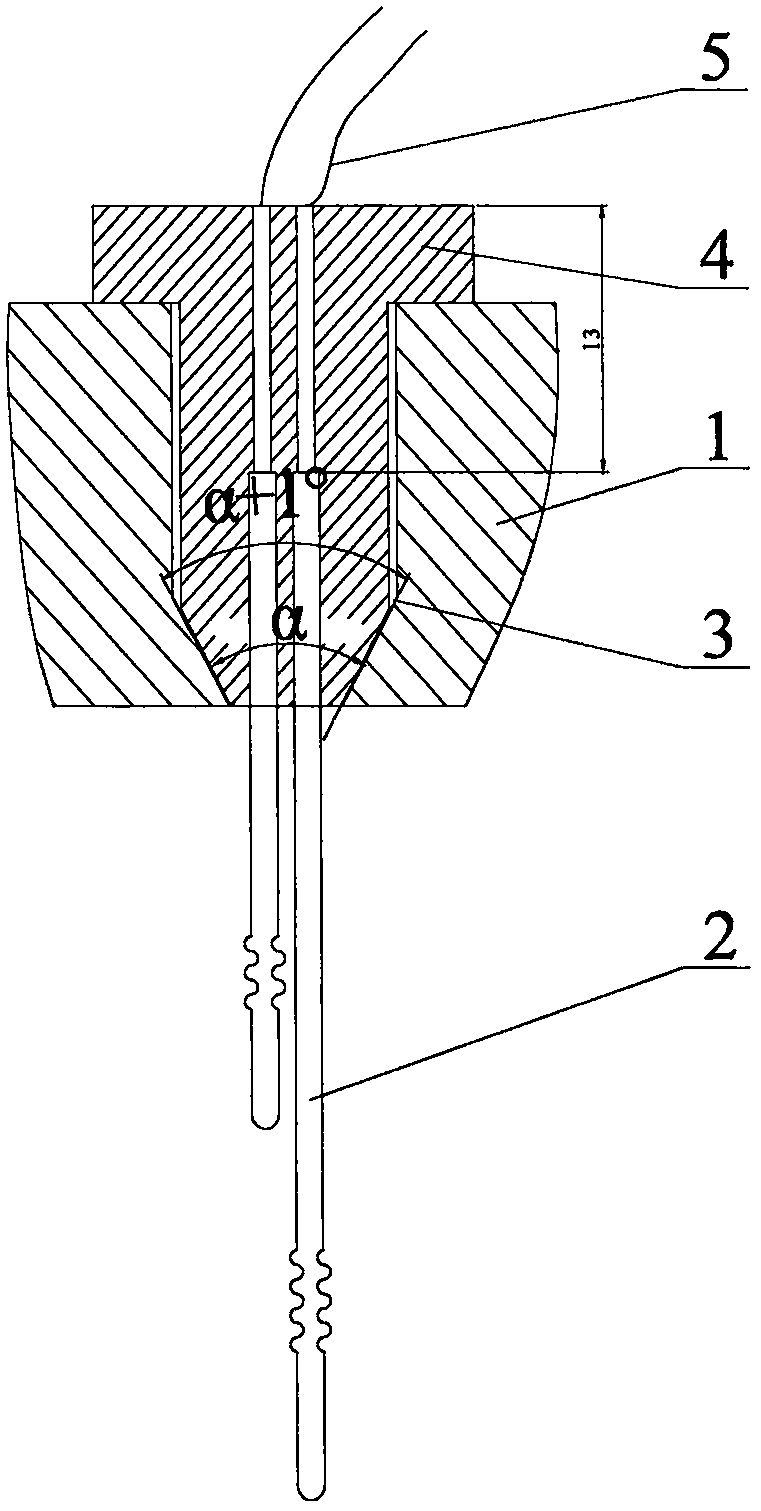

[0012] Specific implementation case 1: The following is combined with the attached figure 1 , to further illustrate the present invention.

[0013] like figure 1 As shown, an ultra-high pressure temperature sensor includes a base 1 , an armored structure 2 , a compression sealing head 3 , a compression nut 4 , and a temperature sensor 5 .

[0014] The connection is carried out through the following steps: in the armored structure, the armored sleeve extends into the inner aperture of the compression sealing head to the aperture step, and is naturally stuck with the compression sealing head, and the outer contact surface is welded by silver welding or tin welding; The compression nut is set on the outside of the compression sealing head, and the sealing surface of the external cone angle of the compression sealing head is in contact with the sealing surface of the inner cone angle of the base. By rotating the hex nut at the end of the compression nut structure, the external th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap