Testing system for scattering peeling resistance of large-aperture water discharging asphalt pavement and method thereof

A technology for draining asphalt and testing systems, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of discrete data, time-consuming, and can not meet the anti-scattering performance of test results, so as to improve the single wheel trajectory and reduce evaluation. The effect of difference in results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

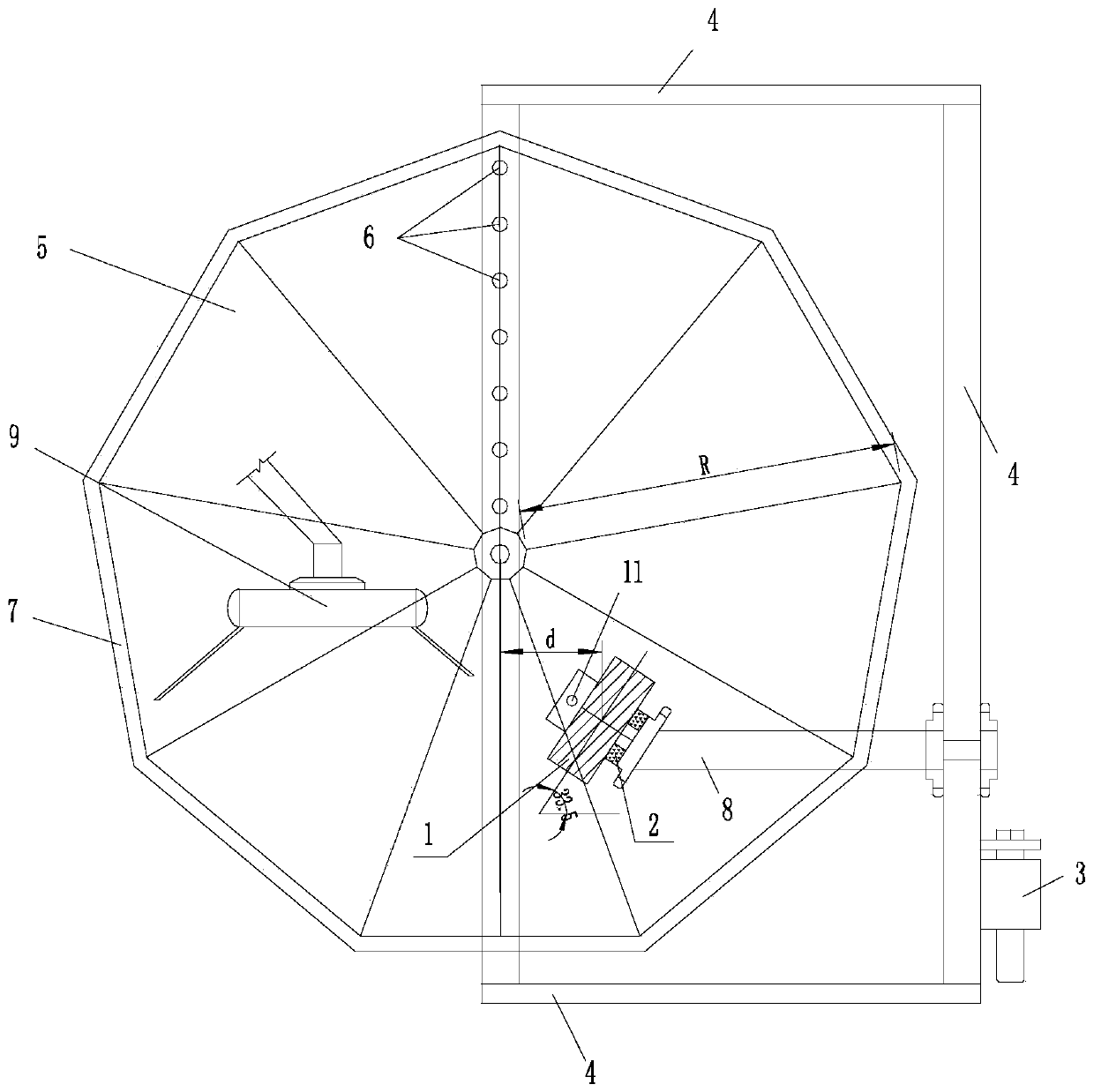

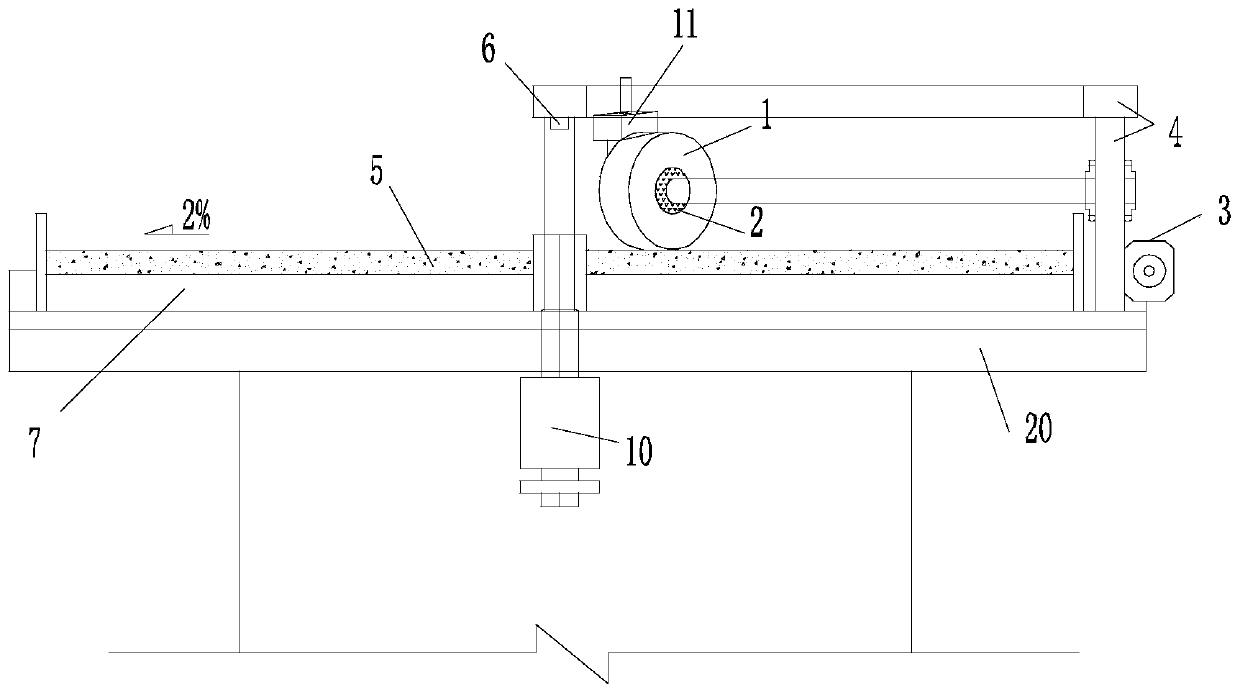

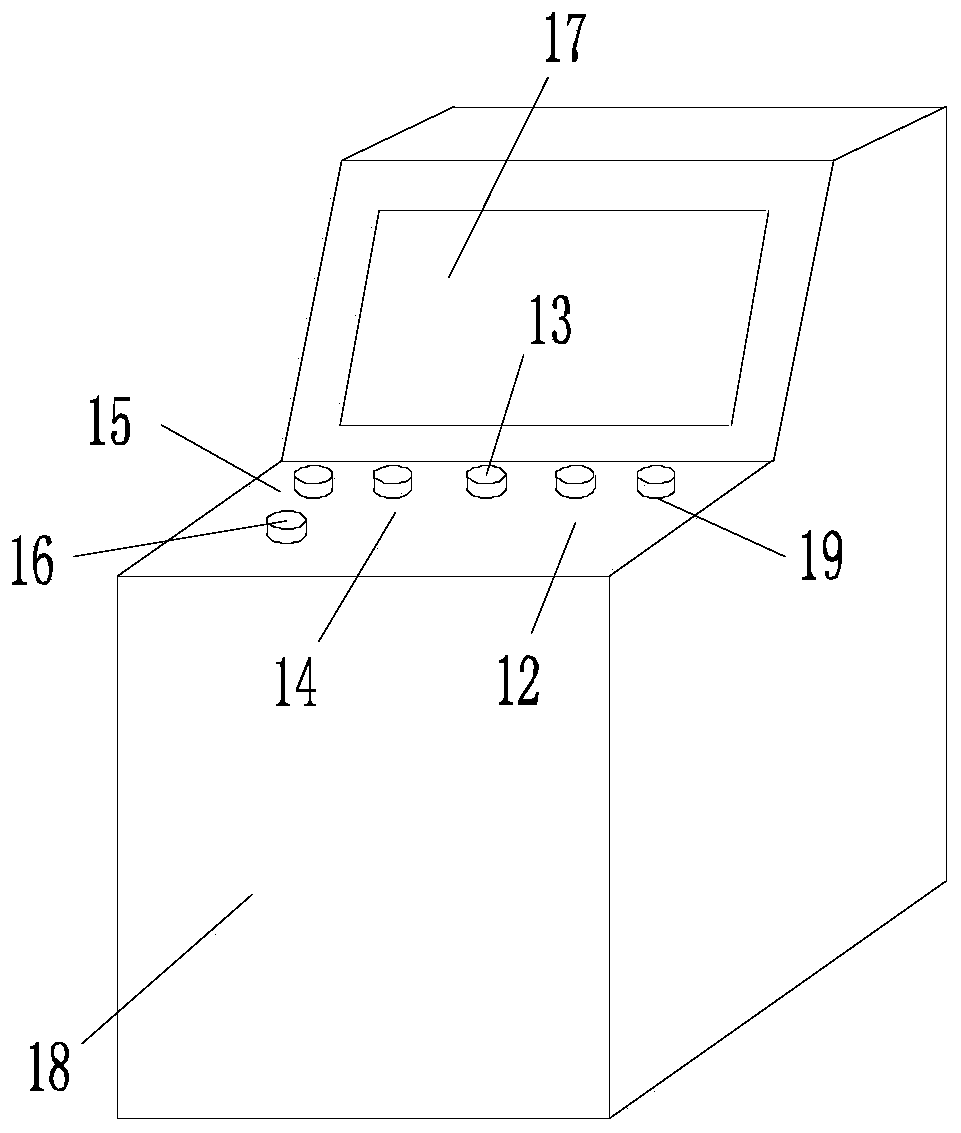

[0052] like Figure 1~3 As shown, the test system for anti-flying and spalling performance of large-gap drainage asphalt pavement includes loading wheel 1, one-way ratchet mechanism 2, first stepping motor 3, rigid frame 4, laser scanning sensor 6, platform base 7, rigid connection Rod 8, scattered particle suction device 9, second stepper motor 10, hydraulic servo loading device 11, control analysis device 18 and base 20;

[0053] The base 20 is provided with a platform base 7, and one end of the base 20 is fixed with a rigid frame 4;

[0054] The power output end of the second stepper motor 10 is connected to the center of the platform base 7 for driving the platform base 7 to rotate;

[0055] The loading wheel 1 is rotationally matched with one end of the rigid connecting rod 8 through the one-way ratchet mechanism 2; the loading wheel 1 is located above the platform base 7;

[0056] The other end of the rigid connecting rod 8 passes through the rigid frame 4 and is fixed...

Embodiment 2

[0068] like Figure 1~3As shown, the test system for anti-flying and spalling performance of large-gap drainage asphalt pavement includes loading wheel 1, one-way ratchet mechanism 2, first stepping motor 3, rigid frame 4, laser scanning sensor 6, platform base 7, rigid connection Rod 8, scattered particle suction device 9, second stepper motor 10, hydraulic servo loading device 11, control analysis device 18 and base 20;

[0069] The base 20 is provided with a platform base 7, and one end of the base 20 is fixed with a rigid frame 4;

[0070] The power output end of the second stepper motor 10 is connected to the center of the platform base 7 for driving the platform base 7 to rotate;

[0071] The loading wheel 1 is rotationally matched with one end of the rigid connecting rod 8 through the one-way ratchet mechanism 2; the loading wheel 1 is located above the platform base 7;

[0072] The other end of the rigid connecting rod 8 passes through the rigid frame 4 and is fixedl...

Embodiment 3

[0089] like Figure 1~3 As shown, the test system for anti-flying and spalling performance of large-gap drainage asphalt pavement includes loading wheel 1, one-way ratchet mechanism 2, first stepping motor 3, rigid frame 4, laser scanning sensor 6, platform base 7, rigid connection Rod 8, scattered particle suction device 9, second stepper motor 10, hydraulic servo loading device 11, control analysis device 18 and base 20;

[0090] The base 20 is provided with a platform base 7, and one end of the base 20 is fixed with a rigid frame 4;

[0091] The power output end of the second stepper motor 10 is connected to the center of the platform base 7 for driving the platform base 7 to rotate;

[0092] The loading wheel 1 is rotationally matched with one end of the rigid connecting rod 8 through the one-way ratchet mechanism 2; the loading wheel 1 is located above the platform base 7;

[0093] The other end of the rigid connecting rod 8 passes through the rigid frame 4 and is fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap