IMPATT diode with double heterojunction and composite passivation layer and manufacturing method thereof

A double heterojunction and passivation layer technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., to achieve the effects of increasing the ionization rate, reducing the width of the avalanche region, and high breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

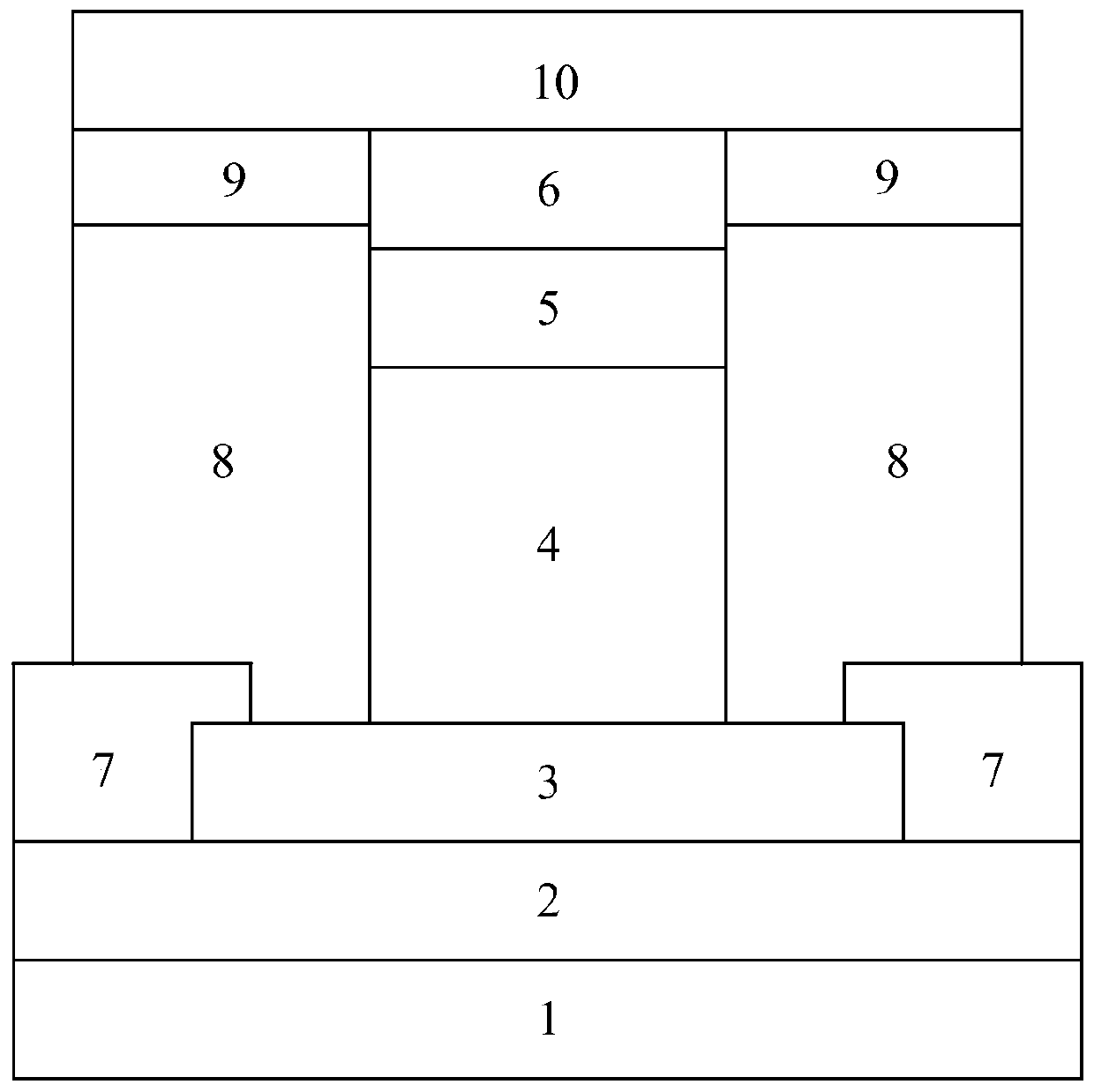

[0050] refer to figure 1 , figure 1 A schematic diagram of an IMPATT diode with a double heterojunction and a composite passivation layer and its preparation method provided by an embodiment of the present invention.

[0051] An IMPATT diode with a double heterojunction and a composite passivation layer provided by an embodiment of the present invention includes:

[0052] substrate layer 1;

[0053] The epitaxial layer 2 is located on the upper layer of the substrate layer 1;

[0054] The ohmic contact layer 3 is located on the upper layer in the middle of the epitaxial layer 1;

[0055] The first drift region 4 is located in the upper layer in the middle of the ohmic contact layer 3;

[0056] The second drift region 5 is located on the upper layer of the first drift region 4;

[0057] Avalanche zone 6, located on the upper floor of the second drift zone 5;

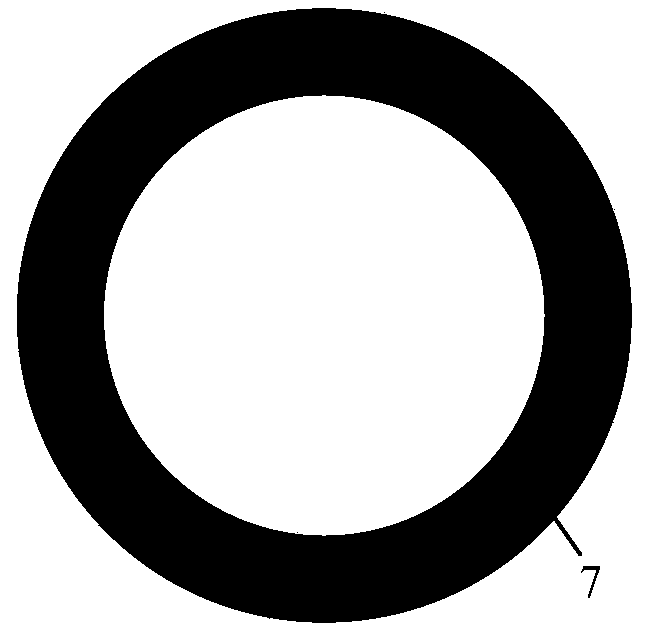

[0058] The ohmic contact electrode 7 is located on both sides of the ohmic contact layer 3 and the upper layer on b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com