Amine-linked c3-glutarimide degronimers for target protein degradation

A CR6R7, compound technology, applied in the field of amine-linked C3-glutarimide degron for target protein degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

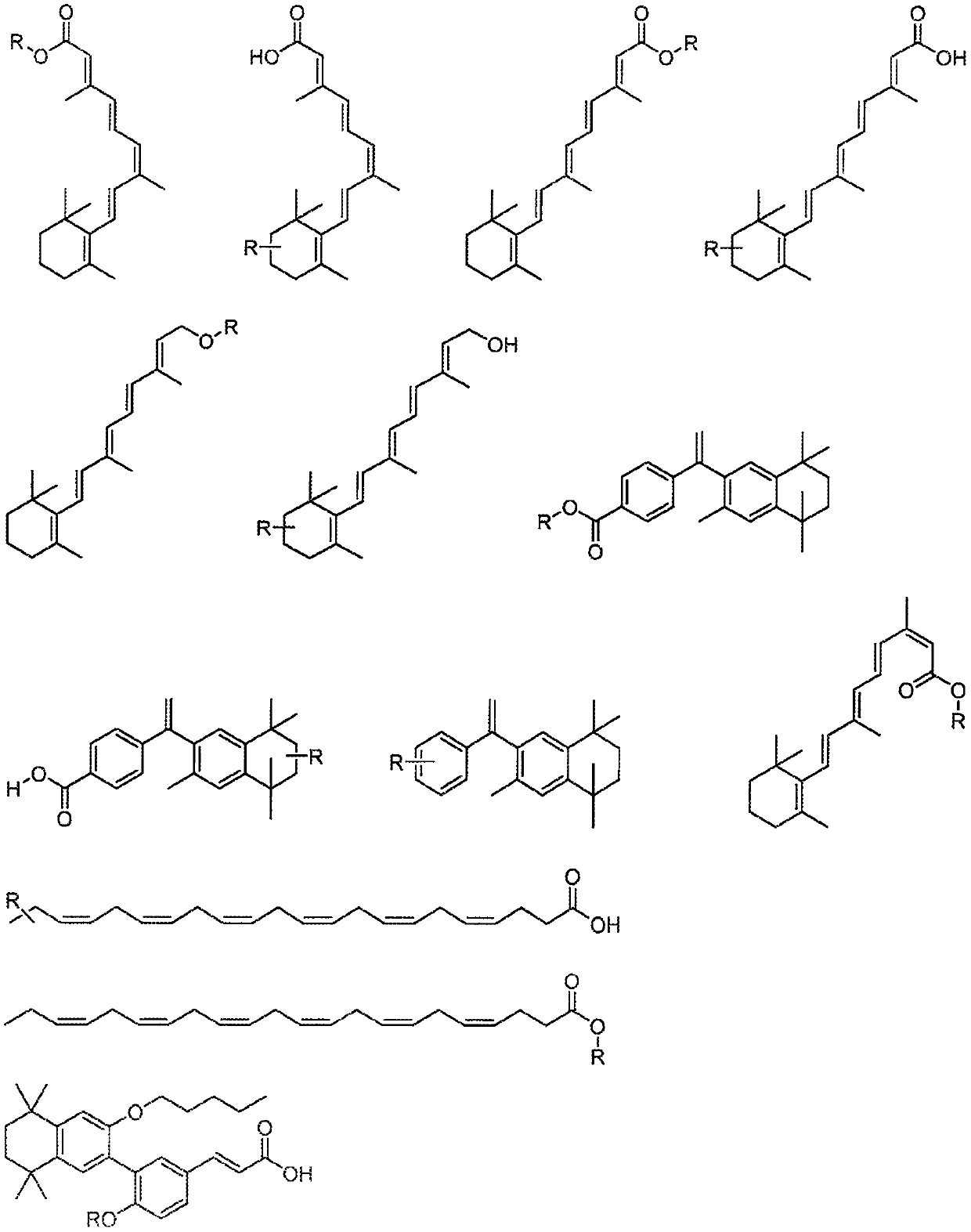

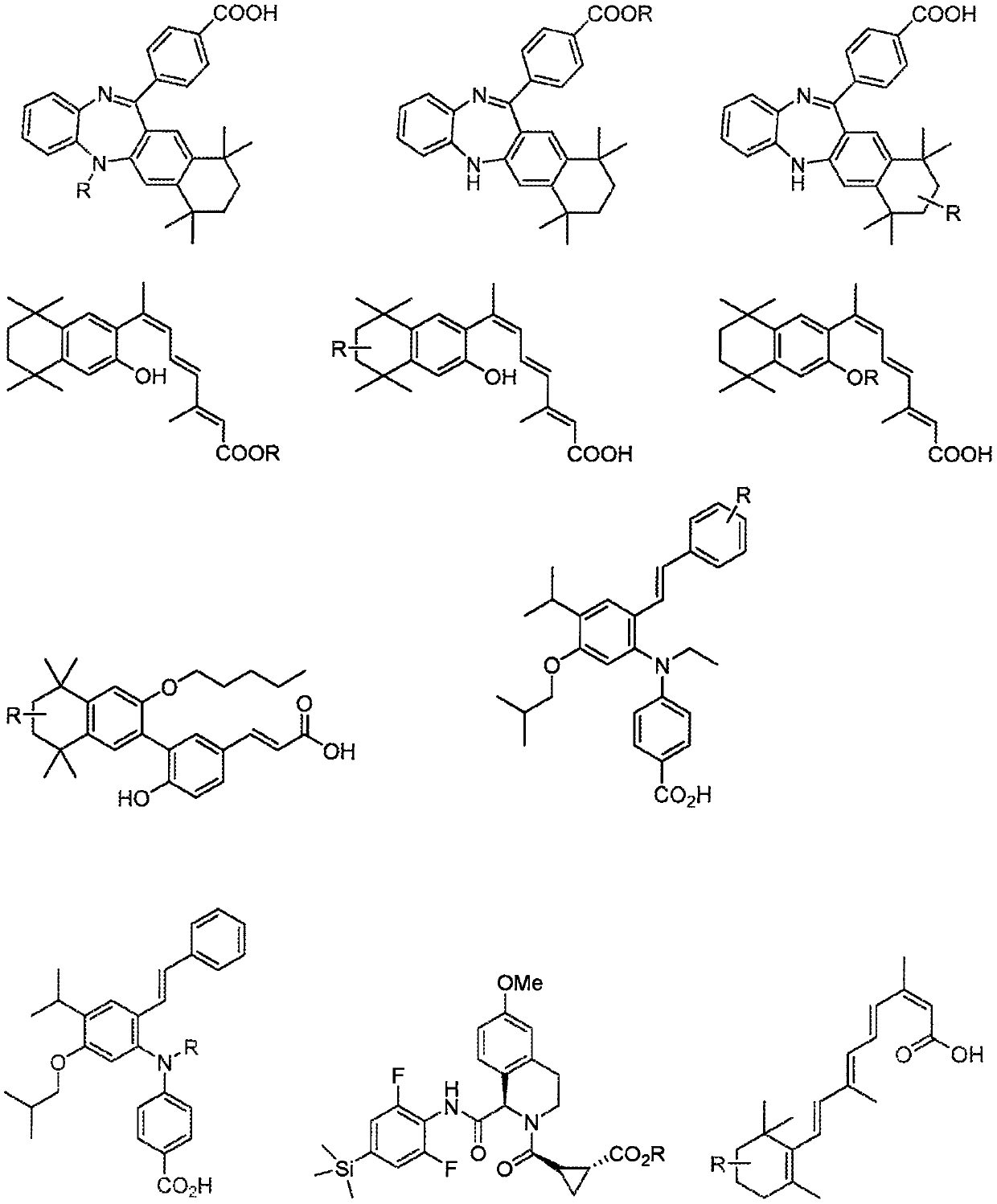

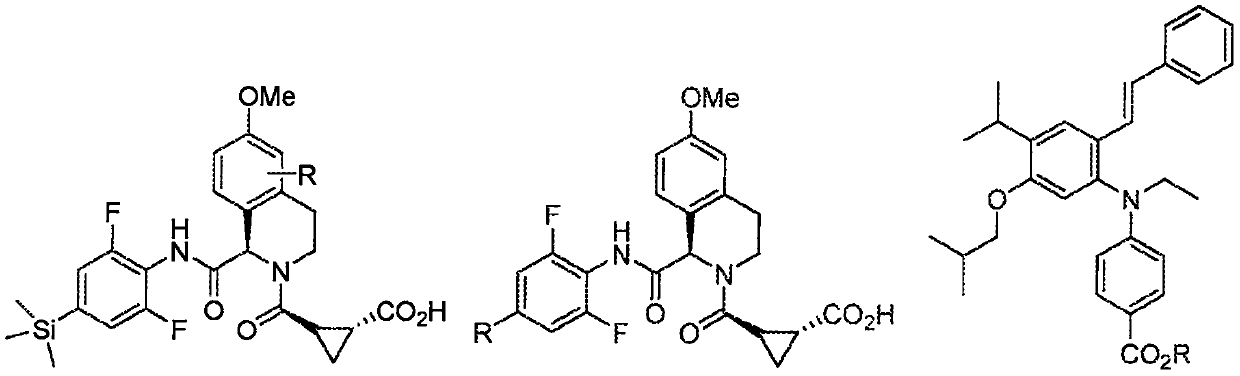

Method used

Image

Examples

Embodiment 3

[1414] Example 3: Exemplary preparation of 3-substituted-2,6-dioxopiperidine intermediates via LHMDS-mediated SN2 on 3-Br-glutarimide

[1415] Option 4:

[1416]

[1417] Preparation of 3-(3-methyl-6-oxopyridazin-1(6H)-yl)piperidine-2,6-dione (compound 148)

[1418]

[1419] Compound 148

[1420] To a stirred solution of 6-methylpyridazin-3(2H)-one 4-1 (300mg, 2.72mmol) in THF (10ml) was added LiHMDS (4.08ml, 4.08mmol) at -30°C and the reaction was stirred The mixture was 1 hour, then 3-bromopiperidine-2,6-dione 2-1 (522 mg, 2.72 mmol) was added, gradually warmed to room temperature, and finally heated under reflux overnight. After TLC showed complete consumption of 4-1, the reaction mass was quenched with ice water, volatiles were removed, the residue was partitioned between ethyl acetate and water, the combined organic extracts were dried over sodium sulfate, concentrated, and chromatographed by column Purification of the residual crude material (eluting with 2% MeO...

example

[1867] (Example procedure: PCT International Application 2008046758, April 24, 2008) To a solution of 4-(benzyloxy)benzaldehyde (1 equiv) in 50 mL of methanol was slowly added potassium cyanide (2 equiv) at room temperature and methylamine.HCl (1.5 equiv) in water (50 mL). The reaction mixture was heated at 40 °C for 2 hours, then at room temperature for 18 hours and monitored by TLC. After completion, the reaction mixture was extracted with 3 x 100 mL of dichloromethane. The organic layer was washed with Na 2 SO 4 Drying and concentration gave the desired 2-(4-(benzyloxy)phenyl)-2-(methylamino)acetonitrile which was used in the next step without further purification.

[1868] step 2

[1869]

[1870] 5-(4-(Benzyloxy)phenyl)-1-methylimidazolidin-2-one:

[1871] A solution of 2-(4-(benzyloxy)phenyl)-2-(methylamino)acetonitrile (1.0 equiv) in THF (0.4M) was added to LiAlH at 0 °C 4 (6.0 equivalents) in suspension in THF (0.4M). The reaction was heated at reflux overnig...

Embodiment 1

[2233] plan 1:

[2234]

[2235] General procedure:

[2236] A mixture of 1-1 (1 mmol) and 1-2 (1 mmol) in dimethylacetamide was heated in the presence of DIPEA (3 mmol) in a sealed tube at 90°C. After TLC showed complete consumption of 1-1, the reaction mixture was cooled, partitioned between ethyl acetate and water, the combined organic extracts were washed with brine, dried over sodium sulfate and concentrated under reduced pressure. The crude material was purified by reverse phase preparative HPLC to afford the desired product 1-3 as a solid.

[2237] General method for preparative HPLC purification:

[2238] method 1

[2239] Preparative HPLC was performed on a Waters automatic purification apparatus equipped with a YMC-Actus Triart C18 (100×30 mm, 5 μ) column, operated at ambient temperature, and the flow rate was 30.0 mL / min. Mobile phase: A = 20mM NH in water 4 HCO 3 , B = acetonitrile; gradient profile: the initial composition of the mobile phase is 80% A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com