Method of efficiently cleaning hydrochloric-acid-process wet-process phosphoric acid

A technology of wet-process phosphoric acid and hydrochloric acid, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high defluorination cost and low impurity removal efficiency, and achieve excellent defluorination effect, easy filtration, and reduced Effect of major impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

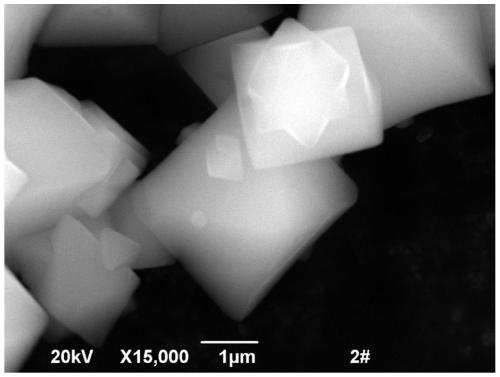

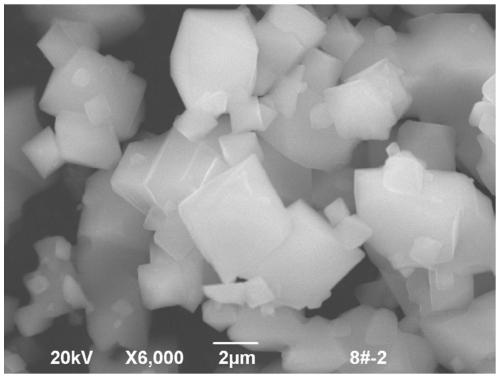

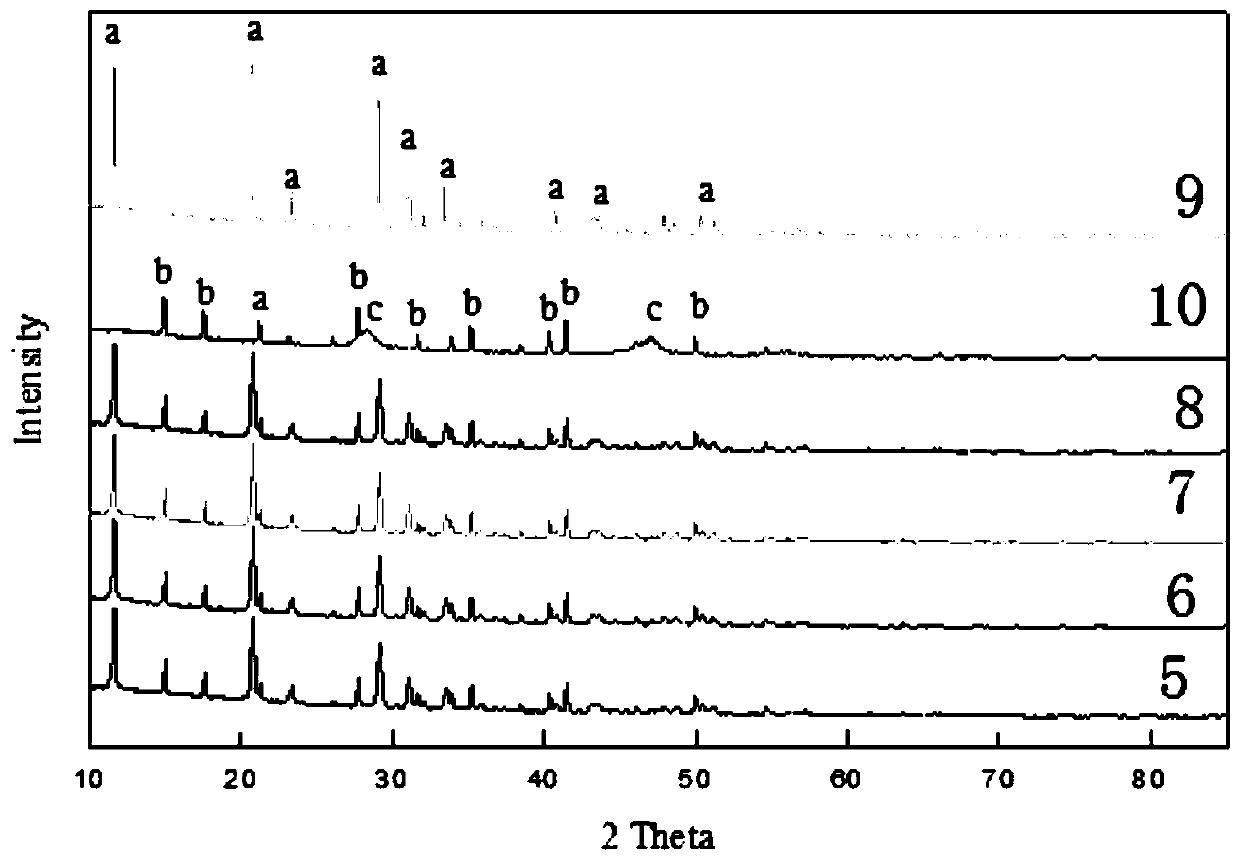

Embodiment 1

[0051] Take a 500mL beaker, weigh 21.11g of 85% phosphoric acid, inorganic substance V (1.84g of 40% HF), inorganic substance II (2.66g of aluminum sulfate octadecahydrate), inorganic substance III (0.32g of silicon dioxide), inorganic substance IV (98% concentrated sulfuric acid 0.88g) is placed in the beaker that fills 166.19g distilled water, after it dissolves, add inorganic substance I (calcium oxide 7.0g), control reaction temperature is 30 ℃, stirring speed is 160r / min, reaction After 12 hours, filter, wash, and dry the precipitate to obtain 0.33 g of white precipitate. F, CaO, and Al in the wet-process phosphoric acid after the reaction 2 o 3 and SiO 2 The removal rates were 14.99%, 8.28%, 13.62%, 6.87%.

Embodiment 2

[0053] Take a 500mL beaker, weigh 21.11g of 85% phosphoric acid, inorganic substance V (1.84g of 40% HF), inorganic substance II (2.66g of aluminum sulfate octadecahydrate), inorganic substance III (0.32g of silicon dioxide), inorganic substance IV (98% concentrated sulfuric acid 0.88g) is placed in the beaker that fills 163.19g distilled water, after it dissolves, add inorganic matter I (calcium oxide 10.0g), control reaction temperature is 30 ℃, stirring speed is 160r / min, reaction After 12 hours, filter, wash, and dry the precipitate to obtain 0.68 g of white precipitate. F, CaO, and Al in the wet-process phosphoric acid after the reaction 2 o 3 and SiO 2 The removal rates were 29.98%, 11.82%, 19.45%, 9.81%.

Embodiment 3

[0055] Take a 500mL beaker, weigh 21.11g of 85% phosphoric acid, inorganic substance V (1.84g of 40% HF), inorganic substance II (2.66g of aluminum sulfate octadecahydrate), inorganic substance III (0.32g of silicon dioxide), inorganic substance IV (98% concentrated sulfuric acid 0.88g) is placed in the beaker that fills 155.51g distilled water, after it dissolves, add inorganic matter I (calcium oxide 17.68g), control reaction temperature is 30 ℃, and stirring speed is 160r / min, reaction After 12 hours, filter, wash, and dry the precipitate to obtain 1.35 g of white precipitate. F, CaO, and Al in the wet-process phosphoric acid after the reaction 2 o 3 and SiO 2 The removal rates were 61.64%, 4.16%, 55.79%, 28.13%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com