Sparkling cider production method

A production method and a technology for cider, applied in the field of cider brewing, can solve the problems affecting the nutritional value, color and taste of cider, insufficient wine aroma, etc., and achieve good market prospects, economic benefits, soft taste, and the effects of helping digestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

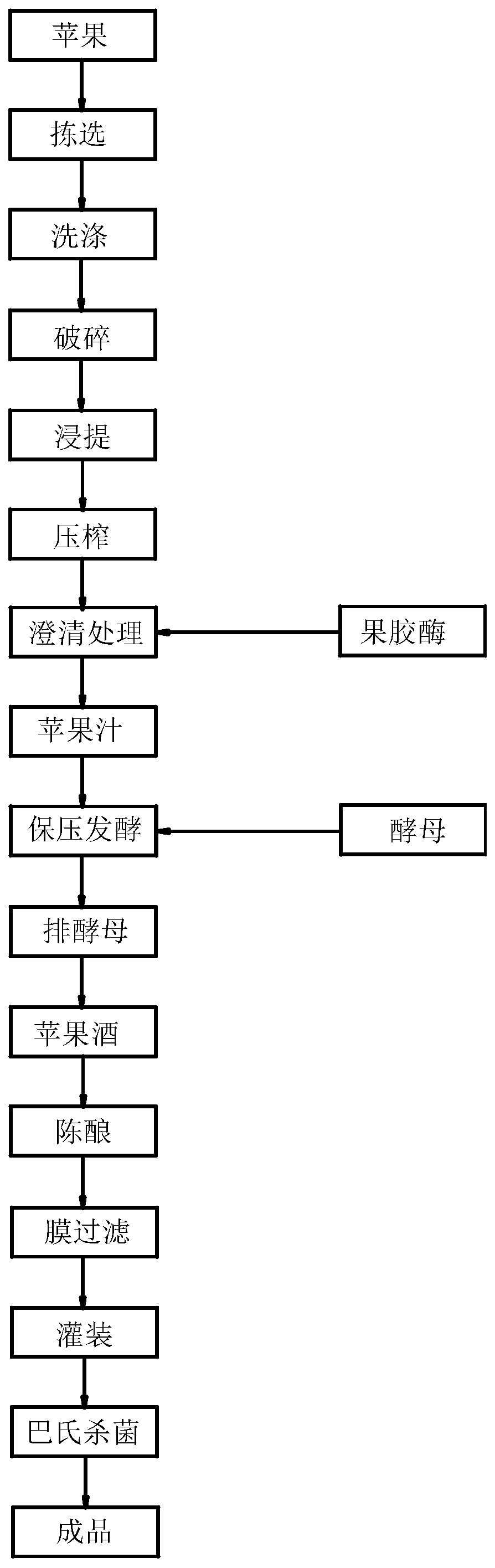

[0032] Such as figure 1 Shown, a kind of preparation method of sparkling cider comprises the following steps:

[0033] a Preparation of apple juice

[0034] a1 Select the picked apples, sort them, remove the raw and rotten fruits, and use the remaining fully ripe and non-rotten apples as raw materials;

[0035] a2 Soak and wash the apple raw materials in running water, and scrub with a brush to thoroughly remove the soil, impurities, and pesticide residues on the apple surface;

[0036] a3 crushing and beating the washed apples, controlling the broken particle size to be 3-5 mm, and obtaining apple slurry;

[0037] a4 Store the apple slurry in the extraction tank for 2-3 hours, so that the apple flesh is softened, and the aroma in the apple peel is dissolved in the apple slurry;

[0038] a5 Select a belt press to continuously squeeze the leached apple slurry, and then filter through a screen to obtain apple juice.

[0039] b clarification

[0040] Pour the apple juice int...

Embodiment 2

[0050] A method for making sparkling cider, comprising the following steps:

[0051] a Preparation of apple juice

[0052] a1 Select the picked apples, sort them, remove the raw and rotten fruits, and use the remaining fully ripe and non-rotten apples as raw materials;

[0053] a2 Soak and wash the apple raw materials in running water, and scrub with a brush to thoroughly remove the soil, impurities, and pesticide residues on the apple surface;

[0054] a3 crushing and beating the washed apples, controlling the broken particle size to be 3-5 mm, and obtaining apple slurry;

[0055] a4 Store the apple slurry in the extraction tank for 2-3 hours to soften the apple flesh, and dissolve the aroma in the apple skin in the apple slurry, and add tannin to the extraction tank at the same time, the amount of tannin added is the weight of the apple slurry The addition of 0.02% of tannin further makes the aroma of apple pulp extraction rich;

[0056] a5 Select a belt press to continuo...

Embodiment 3

[0068] Example 1

[0069] A method for making sparkling cider, comprising the following steps:

[0070] a Preparation of apple juice

[0071] a1 Select the picked apples, sort them, remove the raw and rotten fruits, and use the remaining fully ripe and non-rotten apples as raw materials;

[0072] a2 Soak and wash the apple raw materials in running water, and scrub with a brush to thoroughly remove the soil, impurities, and pesticide residues on the apple surface;

[0073] a3 crushing and beating the washed apples, controlling the broken particle size to be 3-5 mm, and obtaining apple slurry;

[0074] a4 Store the apple slurry in the extraction tank for 2-3 hours, so that the apple flesh is softened, the aroma in the apple peel is dissolved in the apple slurry, and tannin is added to the extraction tank at the same time, the amount of tannin added is the weight of the apple slurry The addition of 0.1% of tannin further makes the aroma of apple pulp extraction rich;

[0075]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com