Satellite-type vacuum film depositing system

A vacuum thin film and deposition system technology, applied in vacuum evaporation plating, ion implantation plating, coating, etc., can solve the problems of large floor area, complex structure, large load-bearing pressure of buildings, etc., to reduce the floor area, Optimize the floor area and reduce the effect of load-bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

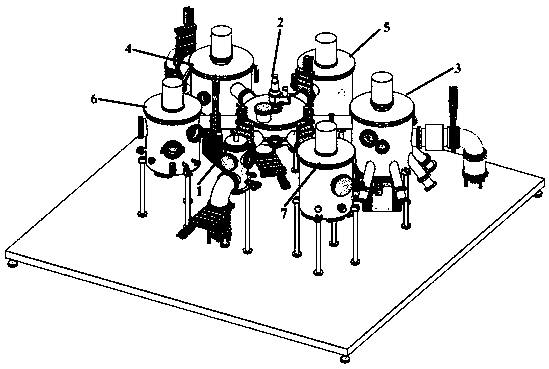

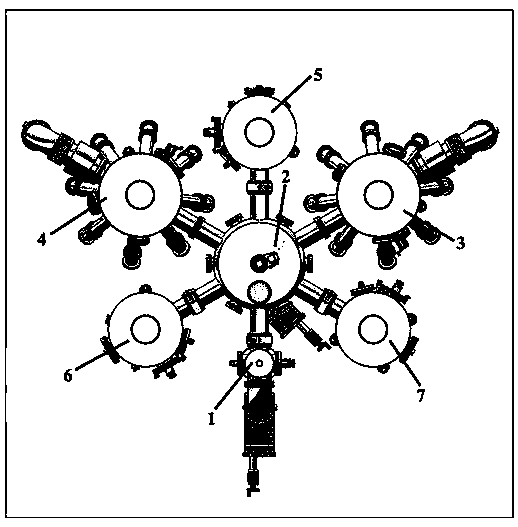

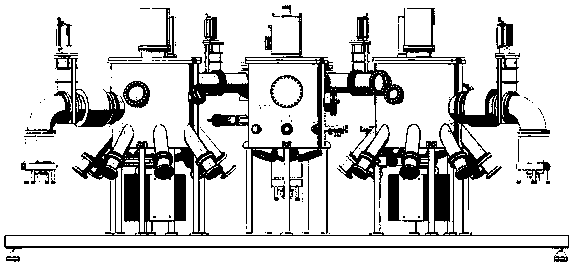

[0029] Such as Figure 1~Figure 3 As shown, the present invention provides a satellite-type vacuum film deposition system, which is mainly composed of multiple operating chambers connected by pipelines. The operating chambers in the whole system are all made of 316 stainless steel. The operating chambers Including a transfer chamber 2, two co-evaporation deposition chambers, three magnetron sputtering chambers and a sample storage chamber 1, each of the operation chambers is equipped with a vacuum pump group for maintaining the vacuum degree of the cavity, and the vacuum pump The group consists of a backing pump and a molecular pump.

[0030] The transfer chamber 2 is located at the center of the entire system, and the other operating chambers are arranged equidistantly around the outer periphery of the transfer chamber 2, and the other operating chambers are respectively connected to the transfer chamber 2 with pipelines, And the gate valve is used for separation. A sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com