Preparation method of activated wood carbon fiber

A carbon fiber and active technology, applied in the field of activated carbon fiber preparation, can solve the problems of complicated process and high production cost, and achieve the effects of simplified process steps, developed pores and strong adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

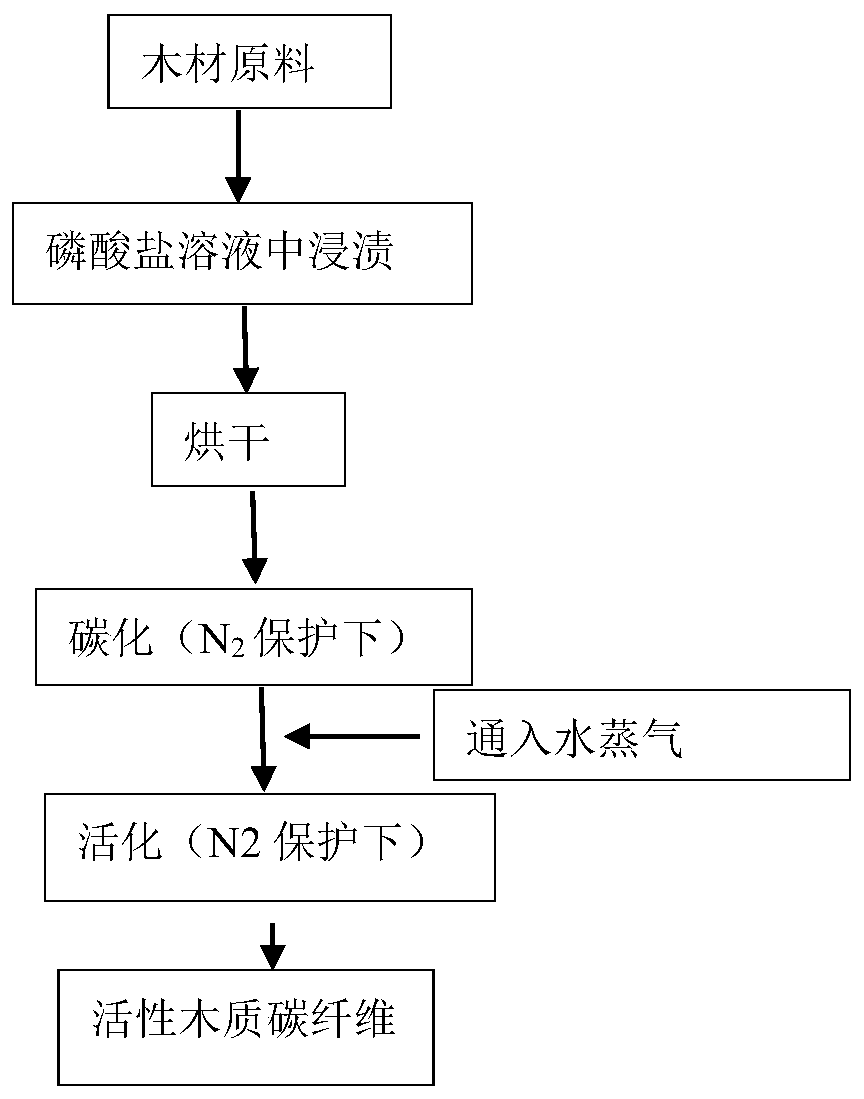

[0031] The preparation of activated carbon fiber, concrete steps are as follows:

[0032] Immerse the wood in 5% ammonium dihydrogen phosphate solution, take it out and dry it after 60 minutes; then put the dried cotton linters into a tube furnace, carbonize and activate it under the protection of nitrogen, and carbonize at 425°C for 60 minutes; Then the temperature was raised to 900°C at a rate of 8°C / min, and activated by passing water vapor for 50 minutes; after the product was naturally cooled, it was taken out, put into a vacuum drying oven, and dried at 60°C for 12 hours to obtain activated woody carbon fibers.

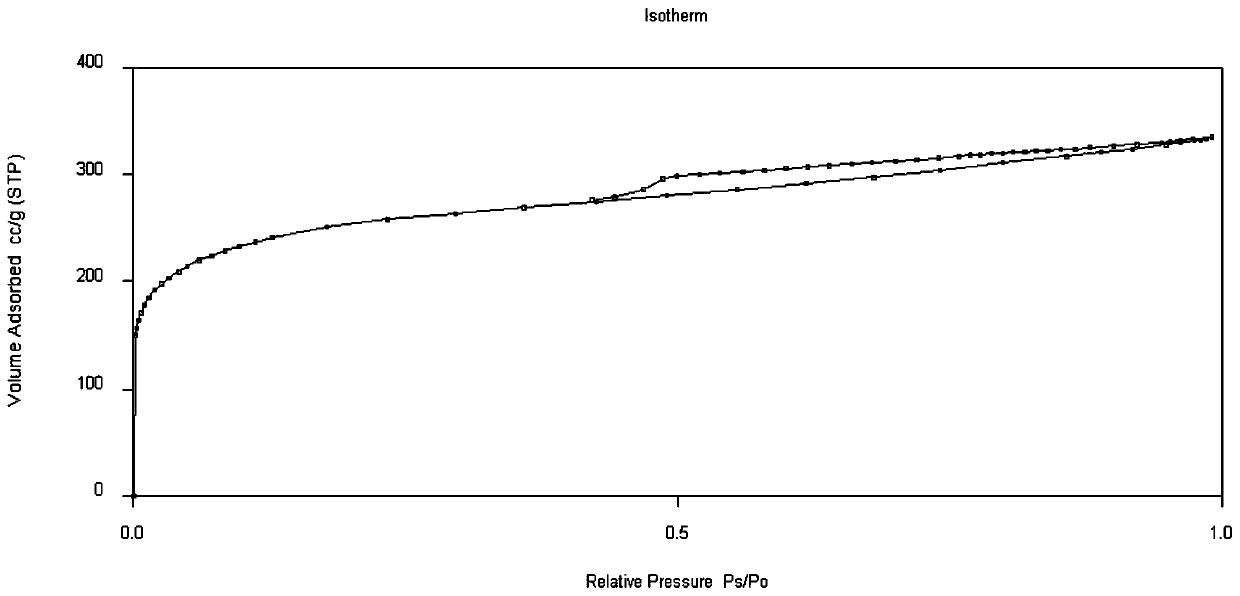

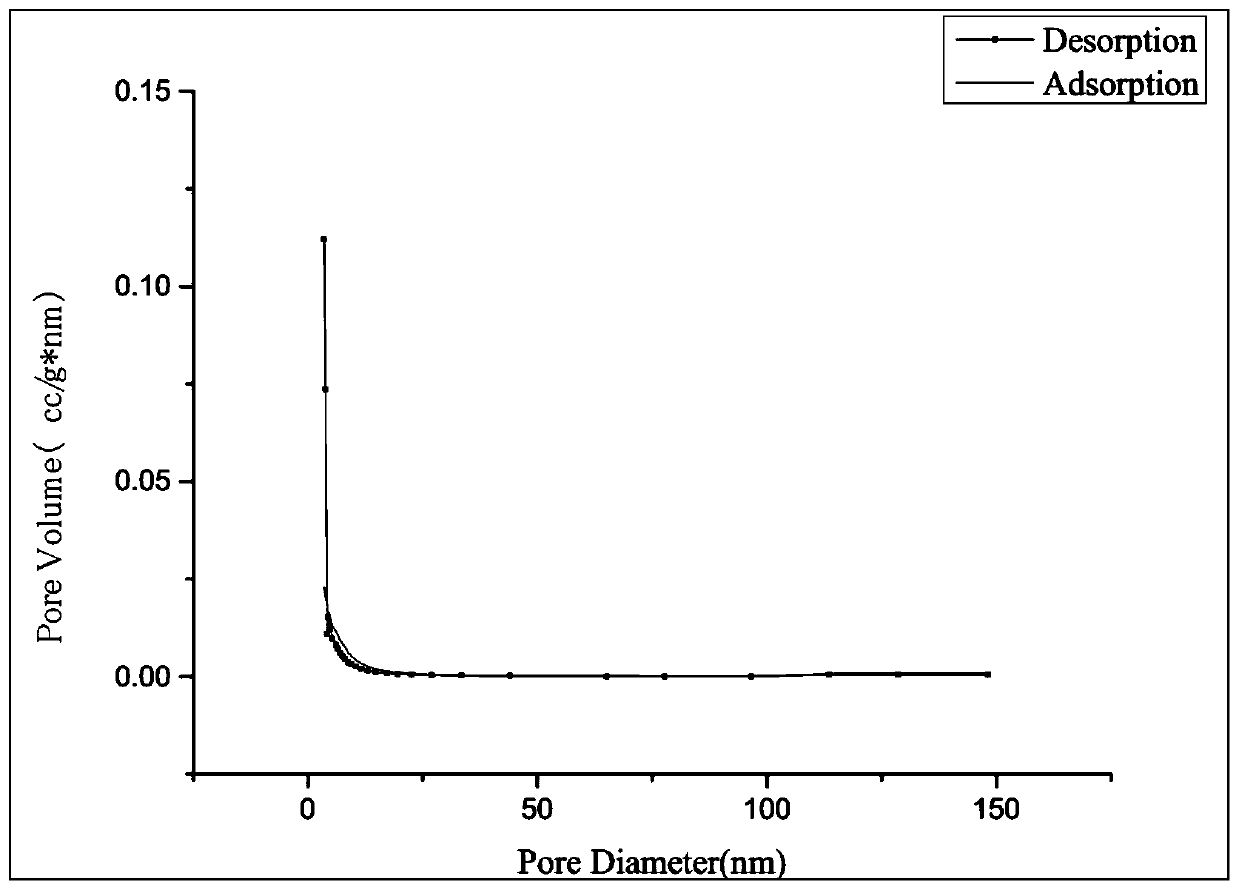

[0033] The nitrogen adsorption-desorption isotherm of the activated carbon fiber that makes in the present embodiment is as follows figure 2 shown by figure 2 It can be seen that the prepared activated carbon fiber has a large number of pores. In the low relative pressure area, due to the filling of the pores, the gas adsorption capacity will increase rapidly...

Embodiment 2

[0038] Immerse the wood in 5% ammonium dihydrogen phosphate solution, take it out and dry it after 60 minutes; then put the dried wood into a tube furnace, and carry out carbonization activation under the protection of nitrogen, and carbonize at 425°C for 60 minutes; then Raise the temperature to 900°C at a rate of 10°C / min, pass in water vapor for activation for 40 minutes; take out the product after natural cooling, put it in a vacuum drying oven, and dry at 60°C for 12 hours to obtain activated woody carbon fibers.

[0039] Further, the activated wood carbon fiber obtained in the present embodiment is tested for adsorption performance, and the specific experimental method and calculation method are the same as in Example 1, and the C 0 =1000mg / L, C e =135.9mg / L, after calculation, the removal rate reaches 86.41%, it can be seen that the active woody carbon fiber has a strong adsorption effect on Congo red.

Embodiment 3

[0041] Immerse the wood in 5% potassium dihydrogen phosphate solution, take it out and dry it after 60 minutes; then put the dried wood into a tube furnace, carbonize and activate it under the protection of nitrogen, and carbonize it at 425°C for 60 minutes; then Raise the temperature to 800°C at a rate of 10°C / min, pass in water vapor for activation for 30 minutes; take out the product after natural cooling, put it in a vacuum drying oven, and dry at 60°C for 12 hours to obtain activated woody carbon fibers.

[0042] Further, the activated wood carbon fiber obtained in the present embodiment is tested for adsorption performance, and the specific experimental method and calculation method are the same as in Example 1, and the C 0 =1000mg / L, C e =281.9mg / L, after calculation, the removal rate reaches 78.11%, it can be seen that the active woody carbon fiber has a strong adsorption effect on Congo red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com