Shale gas remote gas production monitoring and ground pipeline corrosion preventing system and method

A surface pipeline and shale gas technology, which is applied in the pipeline system, measurement, and exploitation of fluids, etc., can solve the problem of missing the best time for drainage to prevent water flooding of gas wells, no concentration monitoring and anti-corrosion evaluation methods, pipeline monitoring gas leakage, etc. problems, to achieve the effect of improving economic and social benefits, avoiding waste of preservatives, and reducing personnel expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

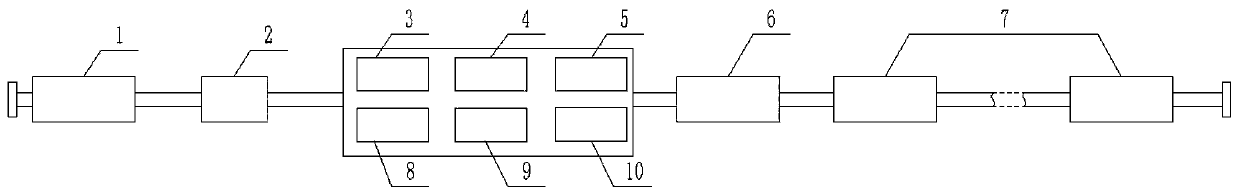

[0031] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0032] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Such as figure 1As shown, the shale gas remote gas recovery monitoring and surface pipeline anticorrosion system provided by the embodiment of the present invention includes: dust reduction and water removal device 1, gas flow acquisition device 2, instrument parameter monitoring device 3, combustible gas composition monitoring device 4, harmful gas Detection device 5 , preservative injection device 6 , preservative detection device 7 , data transmitting device 8 , data monitoring collection and analysis device 9 , energy supply device 10 .

[0034] The dust reduction and water removal device 1 is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com