Method for preparing polysilicon passivation contact structure by tubular PECVD

A contact structure and polysilicon technology, applied in the field of solar cells, can solve the problems of reducing cell yield, increasing production costs, and high equipment prices, and achieve the effects of improving yield, saving costs, and reducing equipment prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

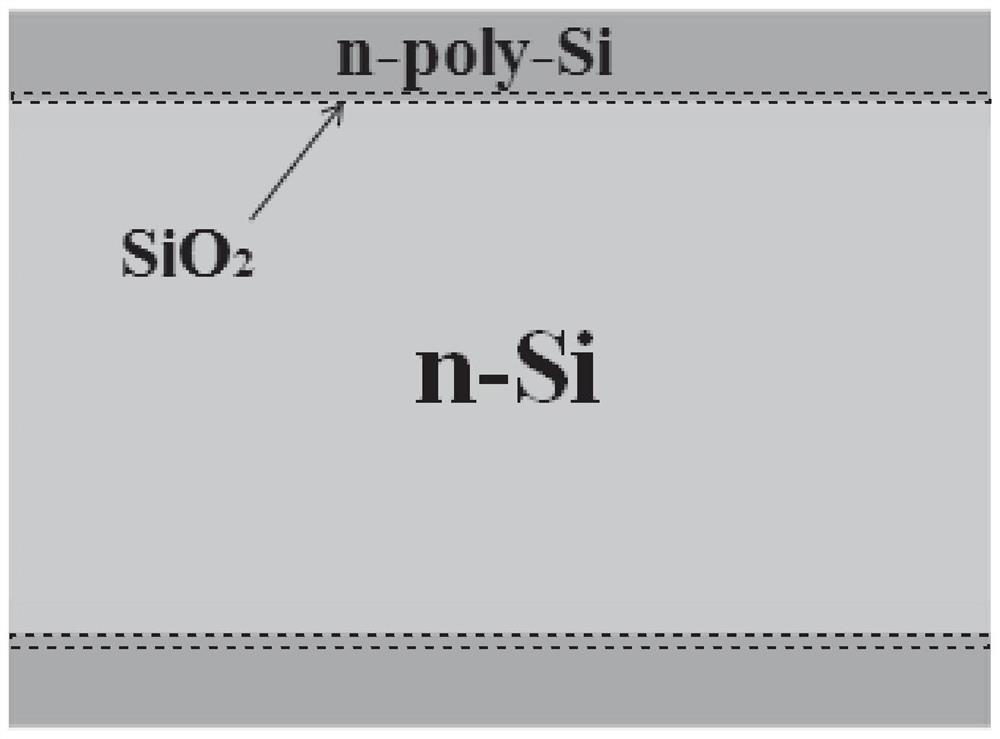

[0056] Using the n-type silicon wafer, remove the damaged layer on the surface, and plate the same structure on both sides. The specific treatment is as follows:

[0057] 1. After the silicon wafer is cleaned, put it into the graphite boat;

[0058] 2. Deposition of silicon oxide: substrate temperature 400 o C, with laughing gas (N 2 O) is the reaction gas, the flow rate is 3000sccm, the air pressure is 200Pa, the deposition power is 2000W, the radio frequency on-off ratio is 2ms: 10ms, and the deposition time is 120 seconds;

[0059] 3. Deposit a layer of phosphorus-doped amorphous silicon film on the silicon oxide layer: substrate temperature 600 o C, SiH 4 :H 2 :PH 3 =1500sccm: 10000sccm: 1500sccm, the air pressure is 250Pa, the deposition power is 2000W, the radio frequency on-off ratio is 3ms: 45ms, and the deposition time is 600 seconds;

[0060] 4. Deposit II layer phosphorus-doped amorphous silicon film on layer I phosphorus-doped amorphous silicon film: substra...

Embodiment 2

[0064] Using the n-type silicon wafer, remove the damaged layer on the surface, and plate the same structure on both sides. The specific treatment is as follows:

[0065] 1. After the silicon wafer is cleaned, put it into the graphite boat;

[0066] 2. Deposition of silicon oxide: substrate temperature 400 o C, as carbon dioxide (CO 2 ) is the reaction gas, the flow rate is 5000sccm, the air pressure is 220Pa, the deposition power is 2500W, the radio frequency on-off ratio is 2ms:30ms, and the deposition time is 120 seconds;

[0067] 3. Deposit I layer phosphorus-doped amorphous silicon thin film: substrate temperature 500 o C, SiH 4 :H 2 :PH 3 =1000sccm: 10000sccm: 1000sccm, the air pressure is 250Pa, the deposition power is 2000W, the radio frequency on-off ratio is 3ms: 75ms, and the deposition time is 500 seconds;

[0068] 4. Deposit II layer phosphorus-doped amorphous silicon film: substrate temperature 500 o C, SiH 4 :H 2 :PH 3 =1000sccm: 10000sccm: 1000sccm, ...

Embodiment 3

[0072] Using the n-type silicon wafer, remove the damaged layer on the surface, and plate the same structure on both sides. The specific treatment is as follows:

[0073] 1. After the silicon wafer is cleaned, put it into the graphite boat;

[0074] 2. Deposition of silicon oxide: substrate temperature 400 o C, with laughing gas (N 2 O) is the reaction gas, the flow rate is 3000sccm, the air pressure is 200Pa, the deposition power is 2000W, the radio frequency on-off ratio is 2ms: 10ms, and the deposition time is 120 seconds;

[0075] 3. Deposit I-layer boron-doped amorphous silicon film: substrate temperature 600 o C, SiH 4 :H 2 :B 2 h 6 =1500sccm: 2000sccm: 1500sccm, the air pressure is 250Pa, the deposition power is 1800W, the radio frequency on-off ratio is 3ms: 45ms, and the deposition time is 600 seconds;

[0076] 4. Deposit II layer of boron-doped amorphous silicon film: substrate temperature 600 o C, SiH 4 :H 2 :B 2 h 6 =1600sccm: 10000sccm: 1600sccm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com