Lithium battery high-temperature fixture formation technique

A lithium battery and jig technology, which is applied in the high-temperature fixture formation process of lithium batteries, can solve the problems of low conductivity battery material ion migration speed, increased battery manufacturing cost, and battery performance degradation, so as to shorten the formation time without affecting battery life. , the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

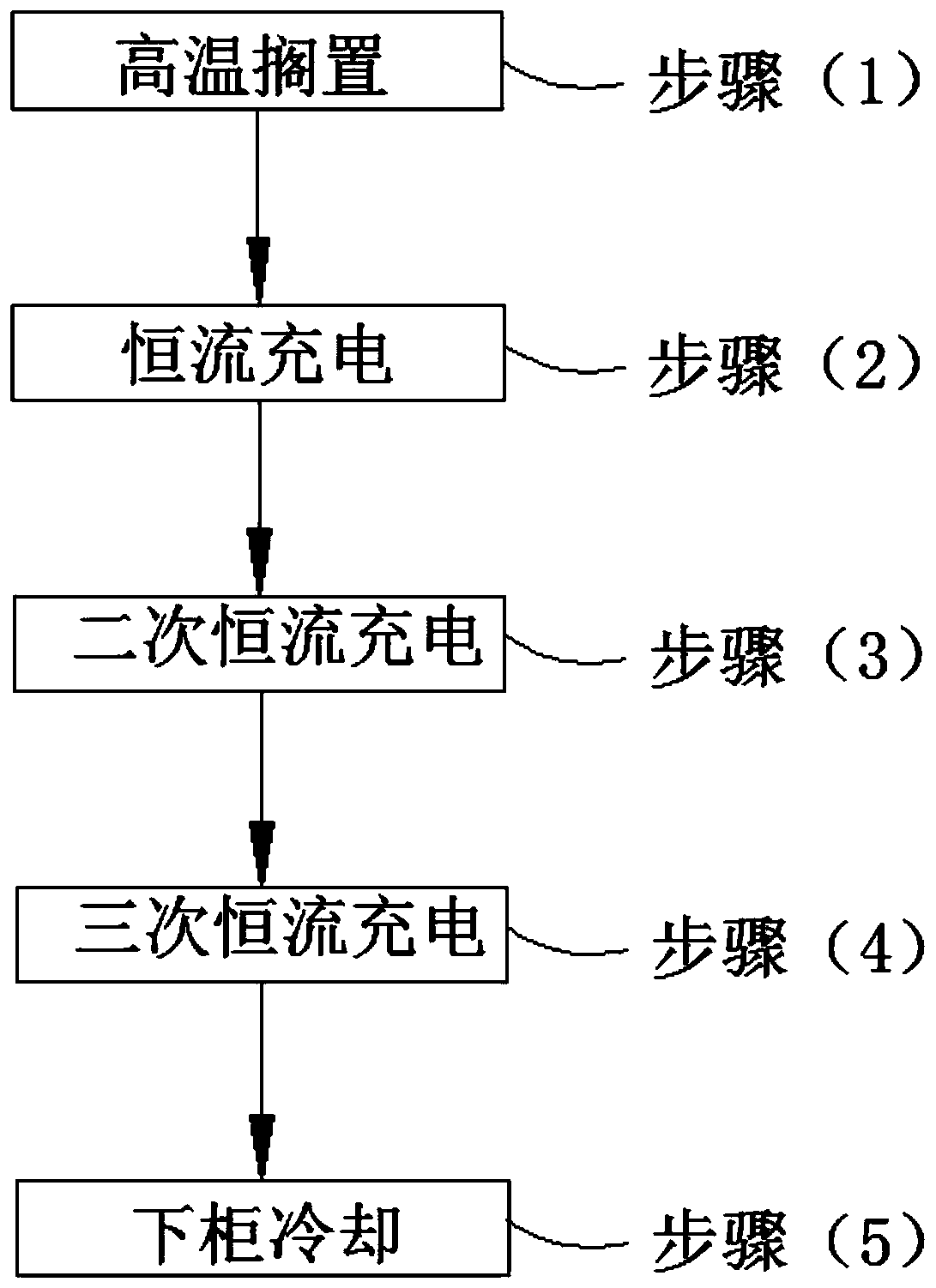

[0023] see Figure 1-Figure 3 , a high-temperature fixture formation process for lithium batteries, specifically comprising the following steps:

[0024] (1) Shelving at high temperature: Shelve the battery cell, clamp the battery cell in the fixture cabinet, raise the temperature of the forming fixture to 80°C, pressurize the battery cell after the temperature reaches, set the pressure to 2Mpa, and set the time to 1min , The formation temperature is set to 80°C, the purpose is to further reduce the viscosity of the electrolyte, increase the conductivity of the electrolyte, increase the ion migration speed of the battery material, and shorten the formation time.

[0025] (2) Consta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com