Method for preparing vinyl chloride-based polymer

A vinyl chloride and polymer technology, applied in the field of vinyl chloride-based polymers, can solve problems such as reduced bulk density, achieve the effects of reduced chlorination reaction time, increased productivity, and excellent whiteness index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

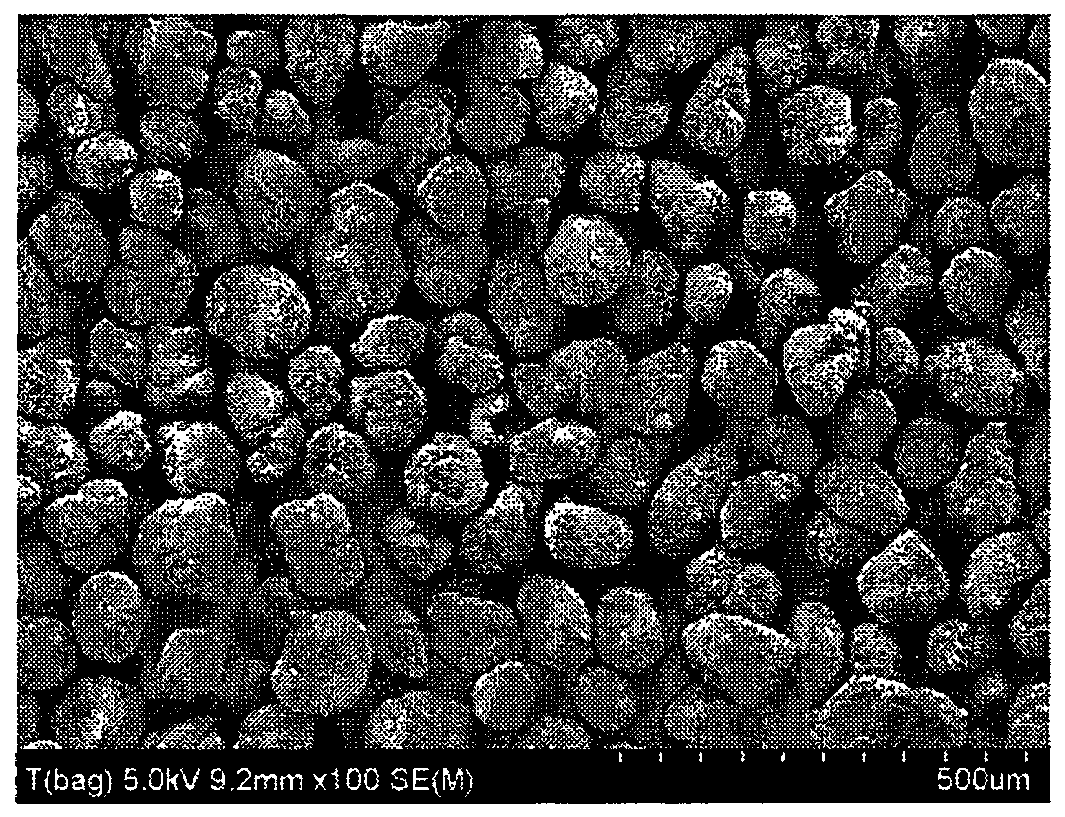

[0077] To a 5L reactor, the reaction initiator and PVA-1, HPMC and PVA-2 suspending agents and 2000 g of deionized water were introduced as described in Table 1 below, and then a vacuum was applied to the reactor using a vacuum pump to remove oxygen in the reactor. Subsequently, 1000 g (100 parts by weight) of VCM was introduced into the oxygen-depleted reactor, and the temperature of the reactor was raised to 58° C. to initiate polymerization, and then a stable standard pressure inside the reactor was confirmed. Thereafter, while maintaining the temperature, the reaction was carried out for 300 minutes, and then when the internal pressure of the reactor decreased by 1.1 kgf / cm compared with the standard pressure 2 , the polymerization was completed, whereby a suspension in which the vinyl chloride-based polymer was dispersed in deionized water was obtained. The suspension was dehydrated and dried to obtain the vinyl chloride-based polymer in the form of spherical particles. ...

Embodiment 2 to 4

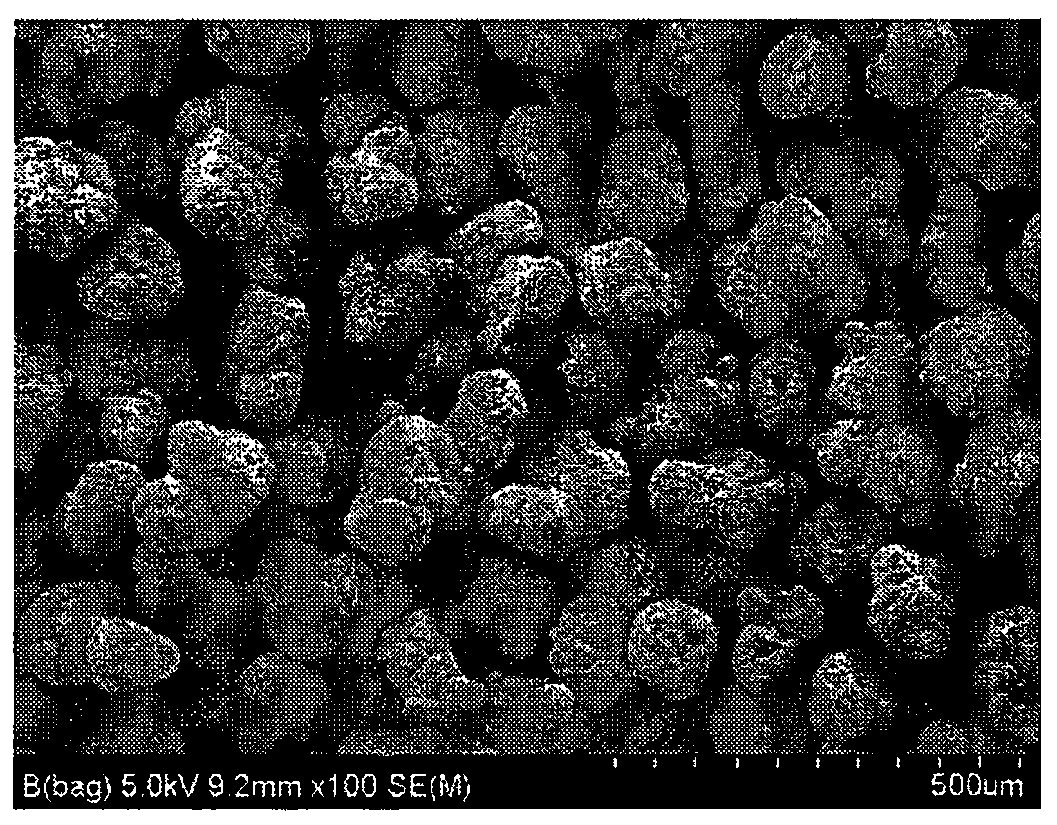

[0079] A vinyl chloride-based polymer was obtained by the same method as in Example 1, except that PVA-1, HPMC, and PVA-2 suspending agents were used as described in Table 1 below.

experiment Embodiment 1

[0089] Properties of the vinyl chloride-based polymers prepared in Examples 1 to 4 and Comparative Examples 1 to 3 were measured as follows, and the results are shown in Table 1 below.

[0090] 1) Average particle size (APS): Measured using a Mastersizer 3000 particle size analyzer (manufactured by Malvern Corporation).

[0091] 2) Dioctyl phthalate absorption rate (CPA): Measured at 25° C. according to ASTM D3367.

[0092] 3) Bulk density (B.D.): Measured according to ASTM D1895-90.

[0093] 【Table 1】

[0094]

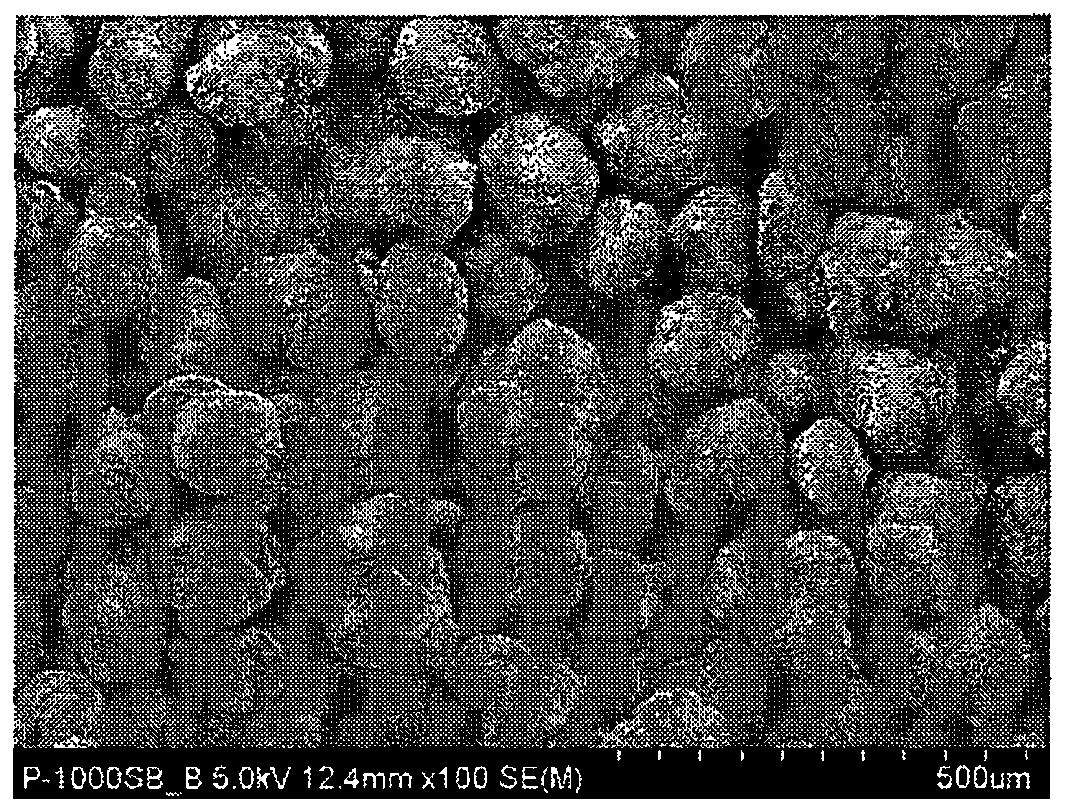

[0095] As shown in Table 1, it can be seen that in the case of Comparative Example 1 in which the PVA-3 suspending agent with a degree of saponification of 80 mol% was used alone, the vinyl chloride-based polymer had the largest average particle diameter, and the lowest CPA.

[0096] In contrast, in the case of Examples 1 to 4 in which PVA-1, HPMC, and PVA-2 were used in combination as a suspending agent, with Comparative Example 2 in which PVA-3, HPMCA, and PVA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com