Wastewater efficient treatment technology

A technology of treatment process and wastewater treatment system, applied in the field of efficient wastewater treatment process, can solve the problems of waste of resources, high cost, energy consumption, etc., and achieve the effects of reducing production costs, reducing operating costs, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

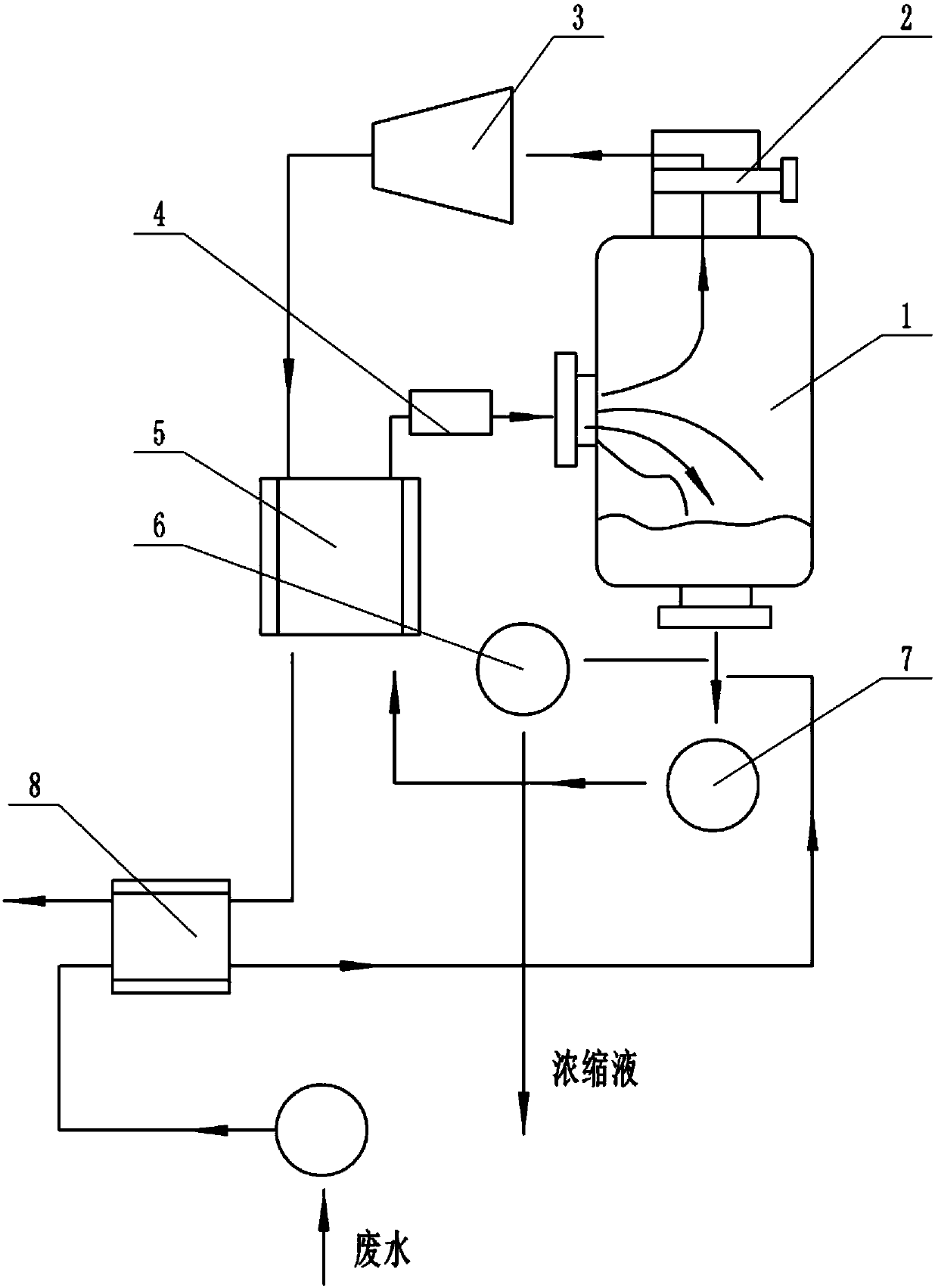

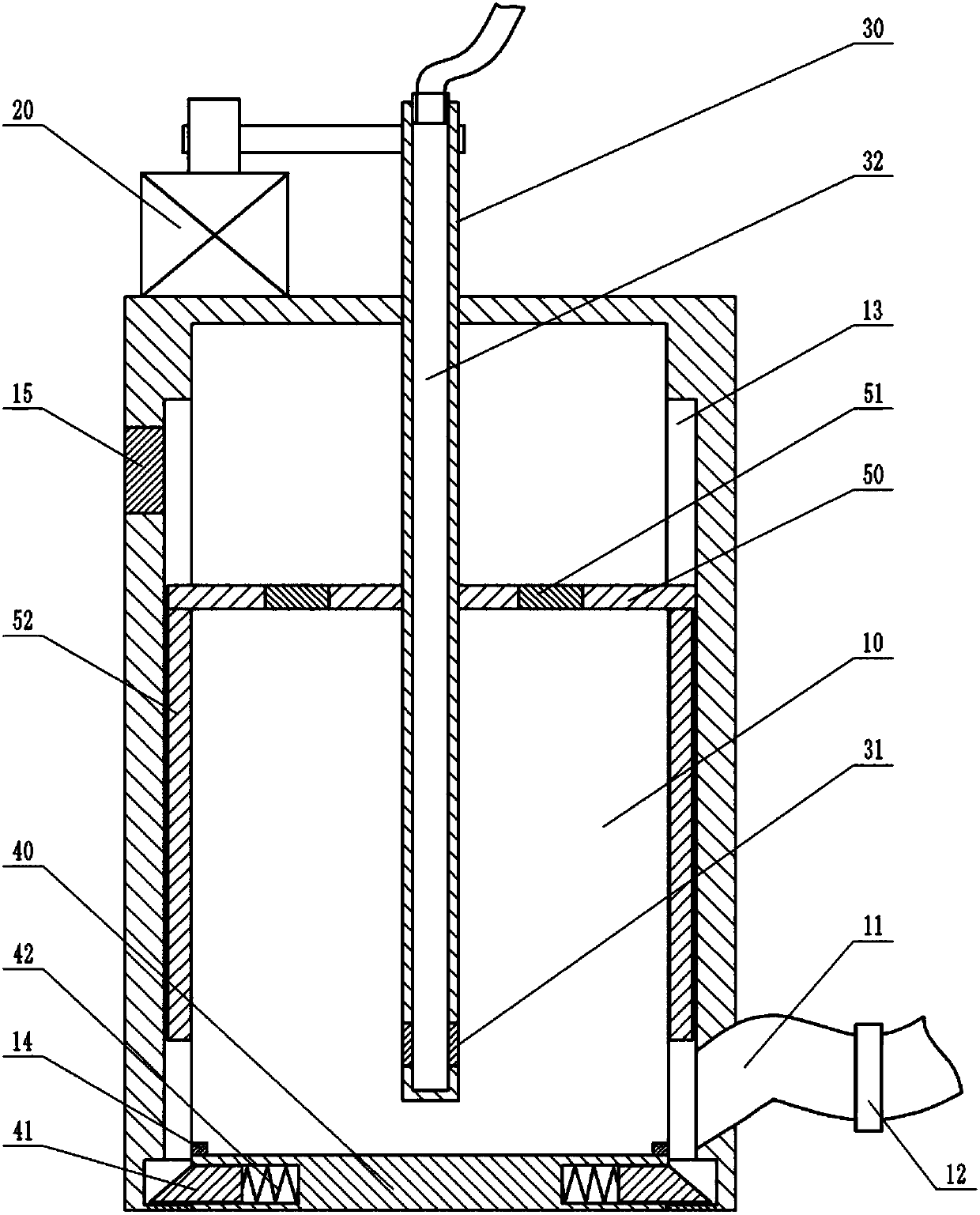

[0023] Instructions attached Figures 1 to 2 The reference signs in include: vapor-liquid separation device 1, demister 2, air compressor 3, heater 4, steam utilization device 5, slag liquid pump 6, circulation pump 7, heat energy utilization device 8, treatment cylinder 10, Liquid inlet pipe 11, first one-way valve 12, strip groove 13, rubber ring 14, pressure valve 15, motor 20, rotating shaft 30, one-way door 31, cavity 32, closing plate 40, wedge 41, spring 42 , Push plate 50, second one-way valve 51, push rod 52.

[0024]An efficient wastewater treatment process, using a wastewater treatment system to treat wastewater. The wastewater treatment system includes a vapor-liquid separation device 1, a steam utilization device 5, an auxiliary heat exchanger 8, an air compressor 3 and a heater 4. In this embodiment, The heater 4 is an electric heater. The lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com