Composite copper plate printing ink applicable to pearl wool sheet material printing and preparation method thereof

A technology of pearl cotton and screen printing ink, applied in the field of composite copper plate ink and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of the composite copper plate printing ink that is suitable for pearl cotton plate printing of the present embodiment is as follows:

[0030] Step a, configure the copper plate ink:

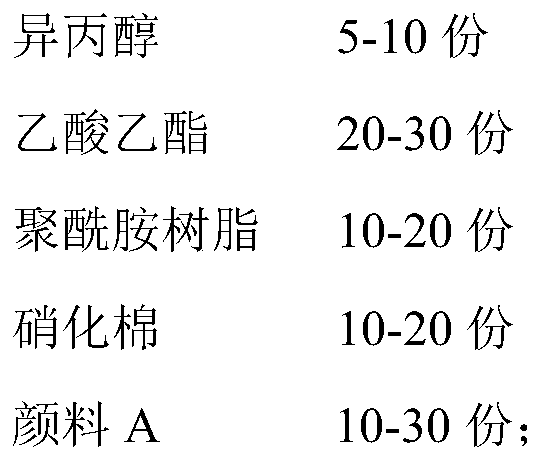

[0031] In parts by weight, add 5 parts of isopropanol and 22 parts of ethyl acetate into stirring container A, add 10 parts of polyamide resin while stirring, then add 6 parts of pigment carbon black, 4 parts of pigment yellow 14 and 5 parts of pigment blue 15:4 and stir evenly, then slowly add 10 parts of nitrocellulose, and stir evenly to obtain copperplate ink;

[0032] Step b, preparing screen printing ink:

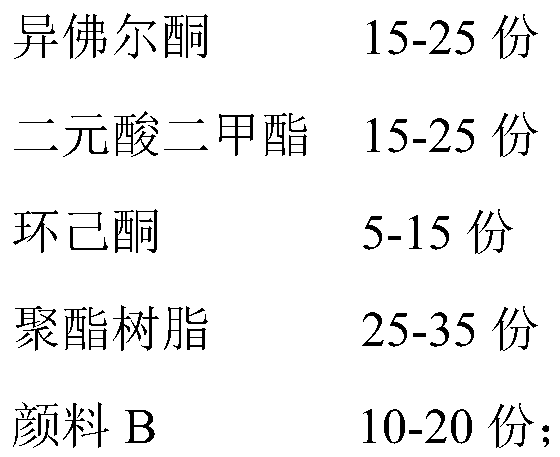

[0033] In parts by weight, add 20 parts of isophorone, 18 parts of dibasic acid dimethyl ester and 5 parts of cyclohexanone into the stirring container B, add 25 parts of polyester resin while stirring, and then add 2 parts of pigment green 7 , 6 parts of Pigment Orange 13 and 2 parts of Pigment Violet 23, after stirring evenly, obtain the screen pri...

Embodiment 2

[0040] A kind of preparation method of the composite copper plate printing ink that is suitable for pearl cotton plate printing of the present embodiment is as follows:

[0041] Step a, configure the copper plate ink:

[0042] In parts by weight, add 8 parts of isopropanol and 26 parts of ethyl acetate into the stirring container A, add 18 parts of polyamide resin while stirring, then add 2 parts of pigment red 48:2, 4 parts of pigment blue 15:4, After stirring 3 parts of Pigment Green 7 and 1 part of Pigment Orange 13 evenly, slowly add 16 parts of nitrocellulose, and stir evenly to obtain copperplate ink;

[0043] Step b, preparing screen printing ink:

[0044] In parts by weight, add 15 parts of isophorone, 22 parts of dibasic acid dimethyl ester and 12 parts of cyclohexanone into the stirring container B, add 28 parts of polyester resin while stirring, and then add 3 parts of pigment white 6 , 5 parts of pigment yellow 14 and 6 parts of pigment red 48:2, after stirring e...

Embodiment 3

[0051] A kind of preparation method of the composite copper plate printing ink that is suitable for pearl cotton plate printing of the present embodiment is as follows:

[0052] Step a, configure the copper plate ink:

[0053] In parts by weight, add 10 parts of isopropanol and 20 parts of ethyl acetate into stirring vessel A, add 15 parts of polyamide resin while stirring, then add 10 parts of Pigment Yellow 14, 16 parts of Pigment Red 48:2 and 4 parts Pigment Violet 23 is stirred evenly, then slowly add 13 parts of nitrocellulose, and after stirring evenly, copper plate ink is obtained;

[0054] Step b, preparing screen printing ink:

[0055] In parts by weight, 25 parts of isophorone, 15 parts of dibasic acid dimethyl ester and 15 parts of cyclohexanone are added in the stirring vessel B, and 32 parts of polyester resin are added while stirring, then 15 parts of carbon black, 5 parts of Pigment White 6, after stirring evenly, the screen printing ink is obtained;

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com