Anti-cracking construction technology for surface layer of waterproof and thermal insulating roof of building slope top structure

A construction technology and architectural technology, applied in the direction of building roofs, building structures, roof coverings, etc., can solve problems such as roof surface layer cracking, achieve the effects of reducing construction period, reducing cracking and cracking, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

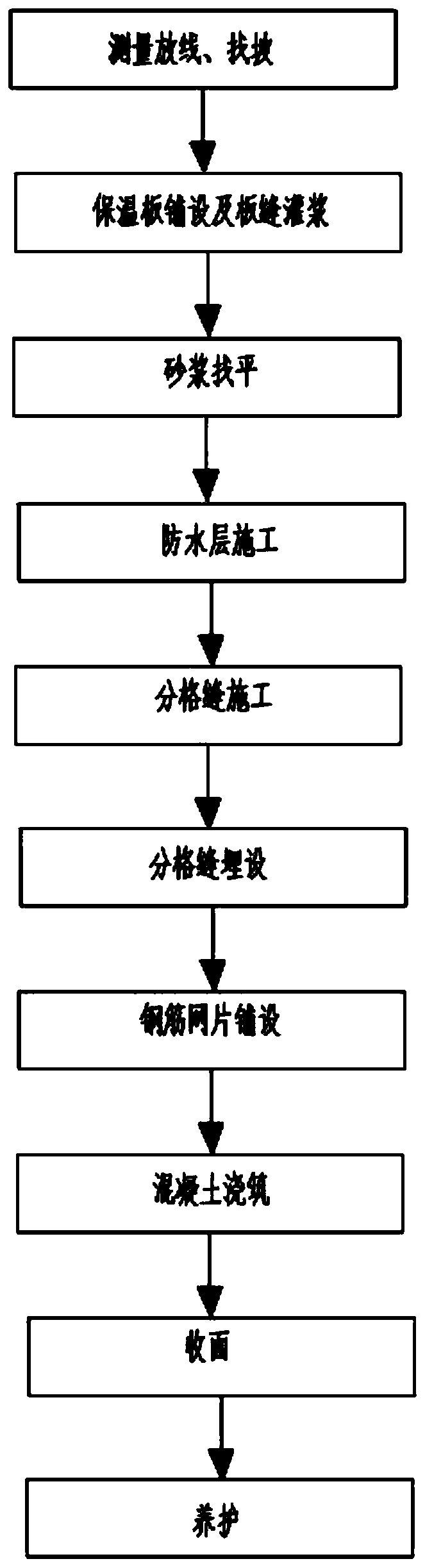

[0024] As shown in the figure, an anti-cracking construction process for a waterproof and thermal insulation roof surface layer of a building body slope roof structure includes the following steps:

[0025] 1. Insulation layer construction:

[0026] (1) Before paving, determine the position of the water dividing line, and find the slope according to the slope direction, and the slope faces the cornice or the cornice outlet.

[0027] (2) Use standard polymer mortar to fully glue the paving, the paving joints are staggered from each other, no error platform should appear between adjacent plates, and the joints of the plates are filled with mortar.

[0028] (3), the insulation layer must be equipped with vent holes and exhaust pipes according to requirements to avoid drumming of the coiled material.

[0029] (4), after the insulation board is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com