Method for quantitatively reconstructing complex boundary contour of interlayer debonding defect based on infrared detection image signal

An infrared detection and image signal technology, applied in image analysis, image data processing, material defect testing, etc., to achieve the effect of improving reconstruction efficiency, small amount of data, and efficient quantitative reconstruction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

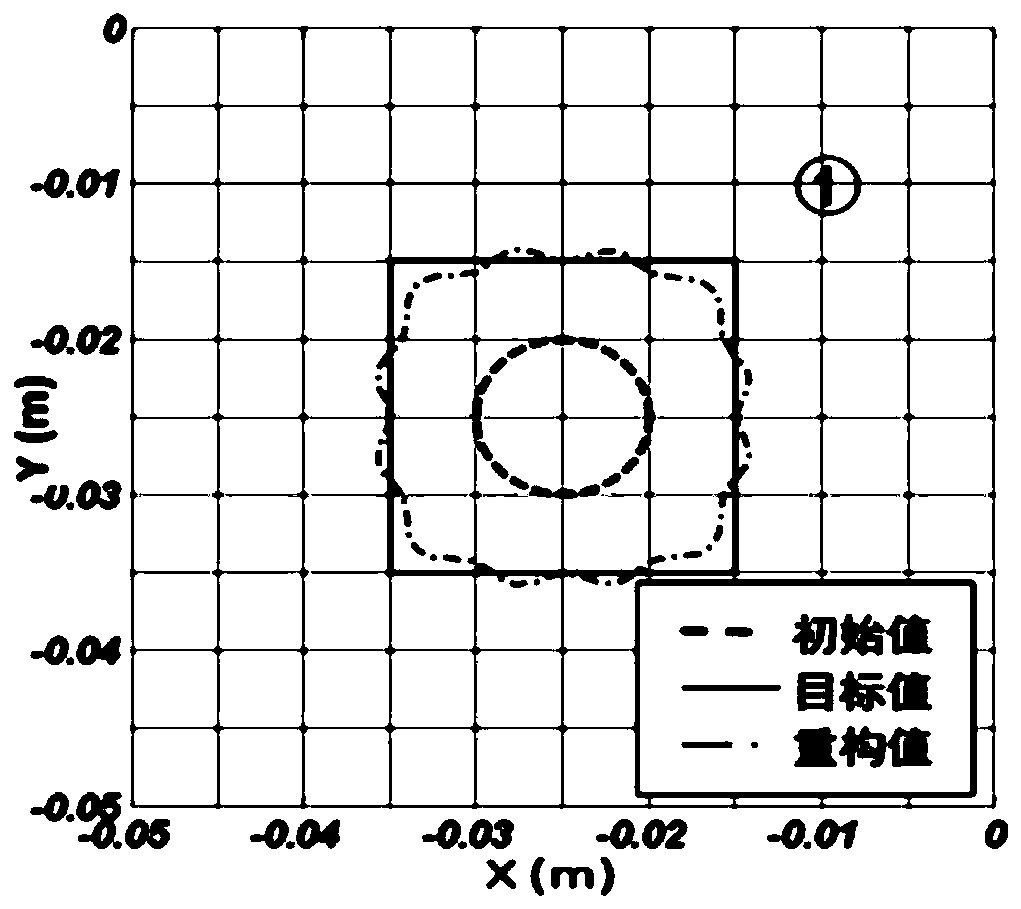

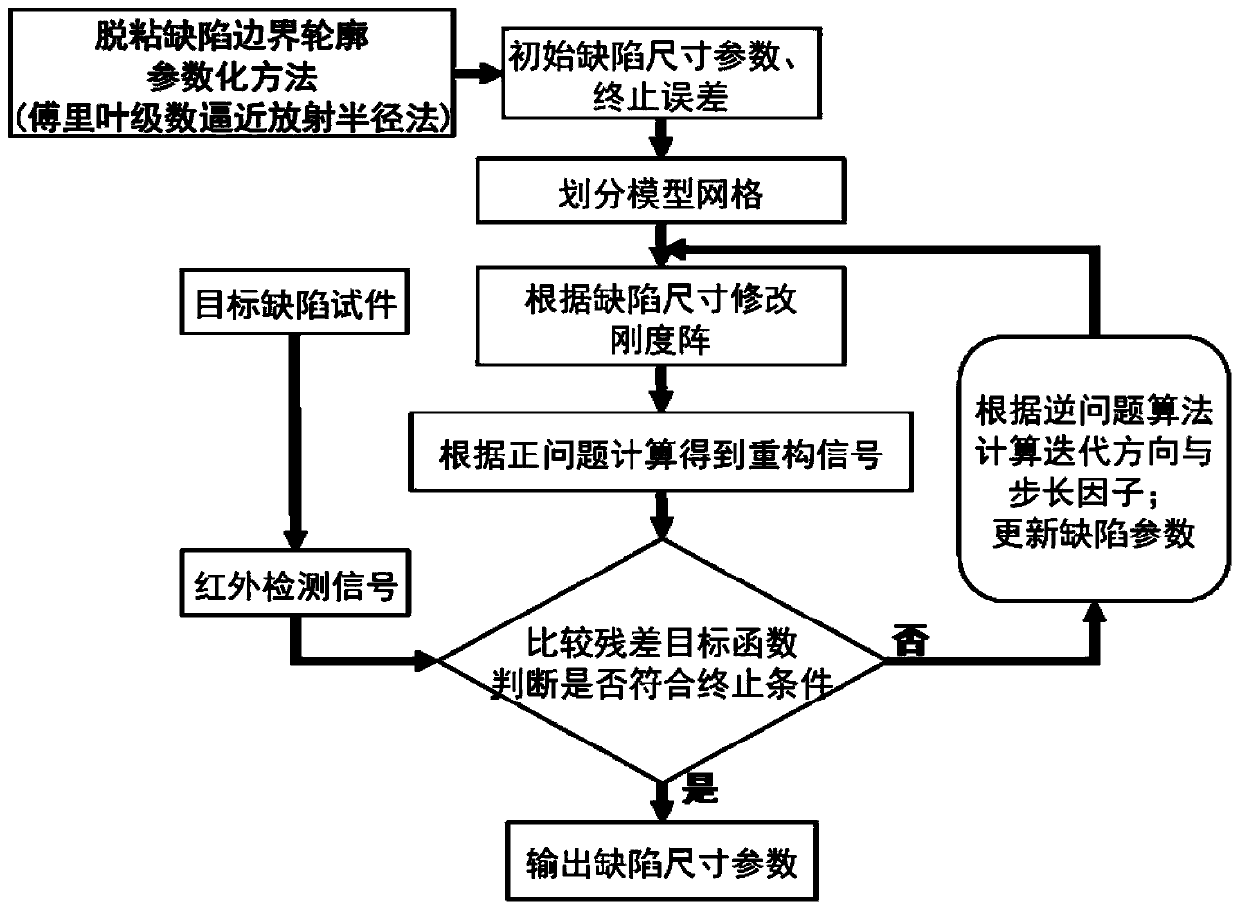

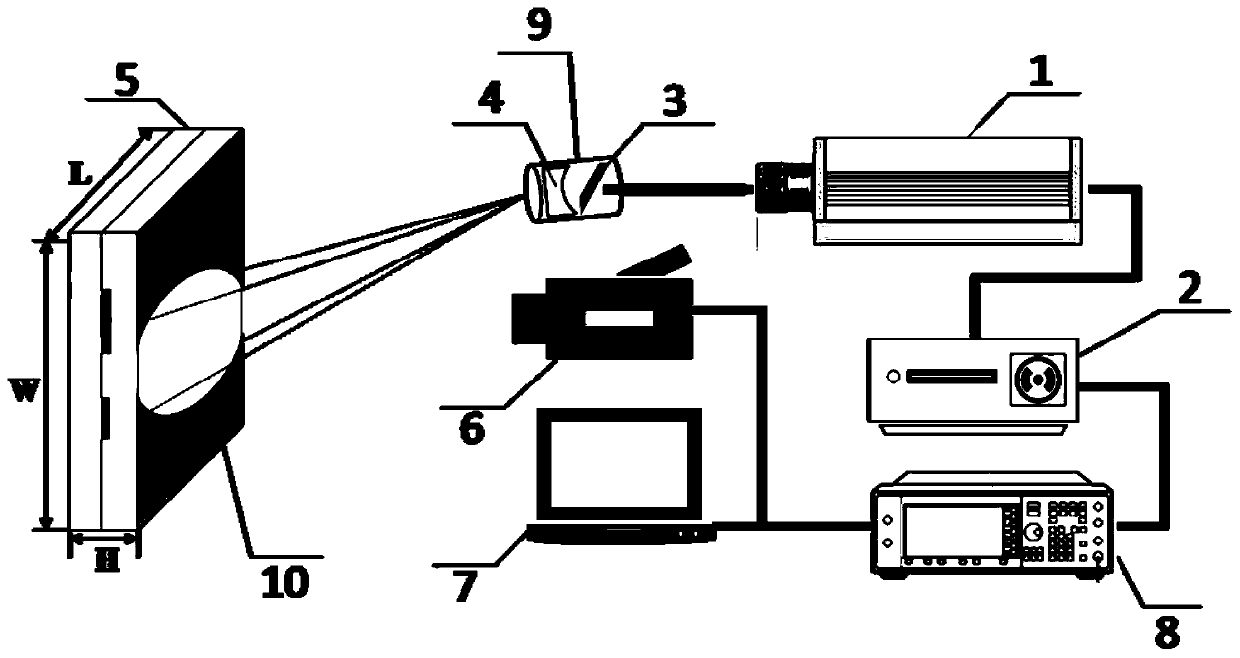

[0045] Such as figure 1 Shown is the quantitative reconstruction flow chart of the complex boundary contour of the debonding defect between the layers of the multi-layer material of the present invention. Firstly, the multi-layer material specimen containing the debonding defect is made, and then the experimental measurement is carried out by using the self-built laser infrared non-destructive testing experimental system. The transient temperature signal on the upper surface of the specimen in the disbonding defect area is obtained and the differential temperature change rate signal is calculated. Secondly, based on the control equation of the transient temperature field, the infrared detection finite element program is written to calculate the transient temperature signal of the simulation numerical model of the test piece. For the debonding complex boundary contour, the Fourier series approximation radiation radius method is used for parametric description . Development of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com