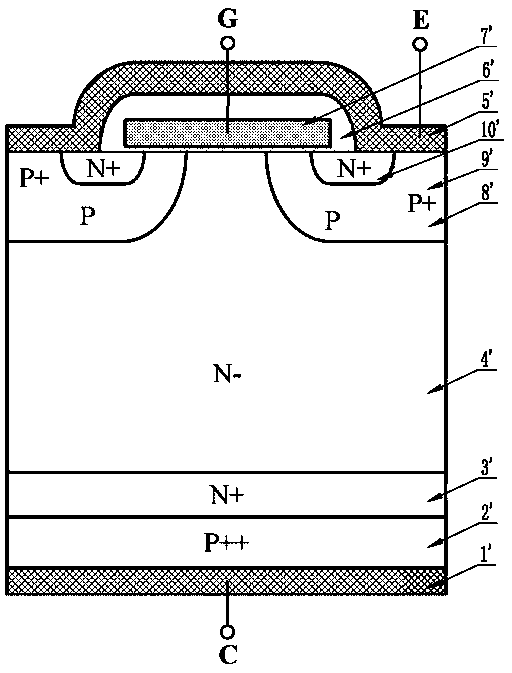

Quick switch IGBT structure

A fast switching and gate structure technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of gate overshoot voltage, large Miller capacitance of devices, and affecting turn-on characteristics, so as to reduce capacitance and improve transient Effect of switching speed and gate charge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

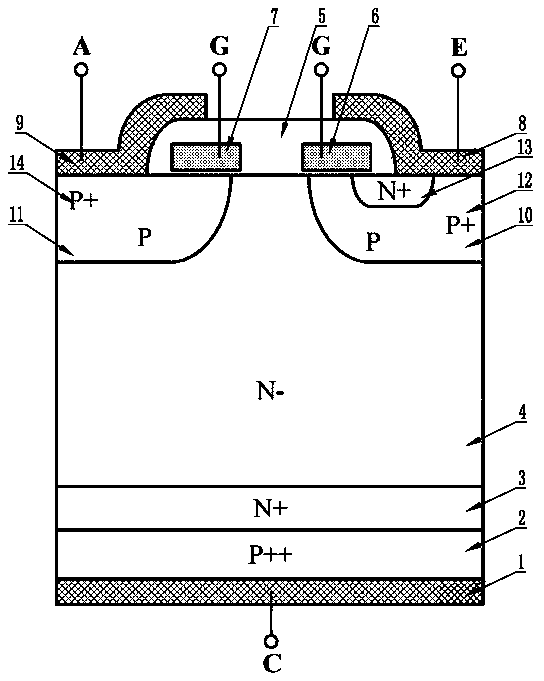

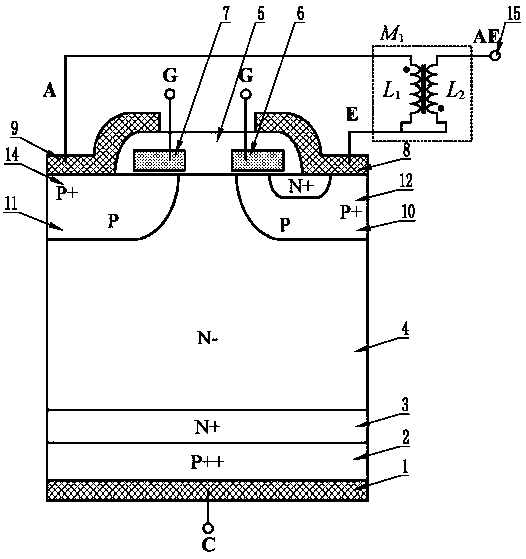

[0021] Such as figure 2 The fast switching IGBT structure shown includes a collector 1, a P++ collector region 2, an N+ buffer region 3, an N-drift region 4, a gate structure and a top metal layer stacked sequentially from bottom to top. Wherein, the gate structure includes a gate dielectric layer 5 , a first gate electrode 6 and a second gate electrode 7 . In this embodiment, the gate structure adopts a planar structure, the gate dielectric layer 5 is disposed on the top of the N-drift region 4 , and the first gate electrode 6 and the second gate electrode 7 are arranged horizontally and separately on the gate dielectric layer 5 . The top metal layer includes an emitter 8 and an auxiliary electrode 9 arranged separately.

[0022] Such as figure 2 As shown, a first P-type base region 10 and a second P-type base region 11 are separately arranged on the upper part of the N-drift region 4 . A first P+ emitter region 12 and an N+ emitter region 13 are arranged on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com