Thermoplastic resin composition, preparation method therefor, and molded product

一种热塑性树脂、组合物的技术,应用在模制件,热塑性树脂组合物领域,能够解决热循环性能易劣化、热循环性能劣化、线性膨胀系数增加等问题,达到优异热循环特性、优异电镀粘合力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

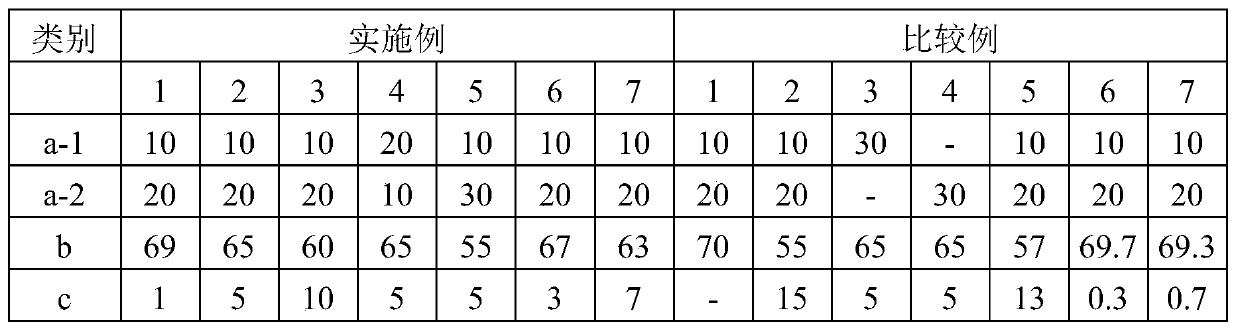

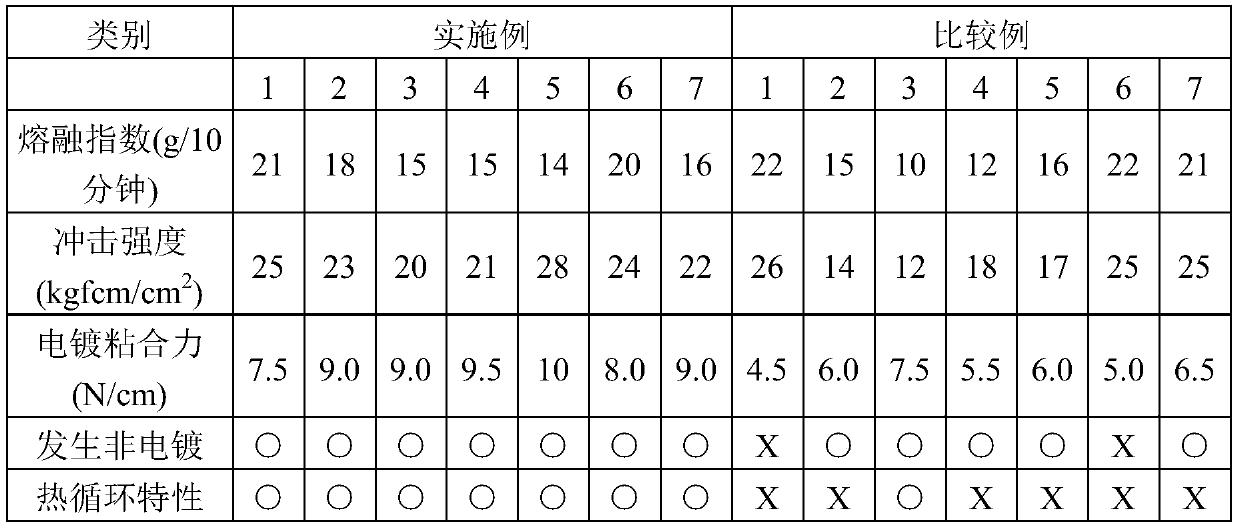

[0046] The preparation method of the copolymer (b) is not particularly limited, and methods commonly used in this field may be appropriately selected. Preferably, the copolymer is prepared by bulk polymerization. More preferably, in consideration of reducing production costs, the copolymer is prepared by a continuous bulk polymerization method.

[0047] Alkyl (meth)acrylate polymer (c) is added in order to improve plating adhesion and reduce electroless phenomena while improving mechanical, thermal and processability during a less toxic plating process.

[0048] For example, the content of the alkyl (meth)acrylate polymer in the composition may be 1% to 10% by weight, 3% to 10% by weight, 5% to 10% by weight, 5% to 8% by weight % by weight or 3% by weight to 7% by weight. Within the range, the composition may be excellent in mechanical and thermal properties, workability, and plating adhesion properties may be improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com