Alkali recovery boiler tail gas cyclic treatment method and equipment

A technology of alkali recovery boiler and treatment method, which is applied in the field of papermaking industry, can solve the problems such as non-compliance with emission requirements and impact, achieve the effect of improving desulfurization efficiency and reducing on-site wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

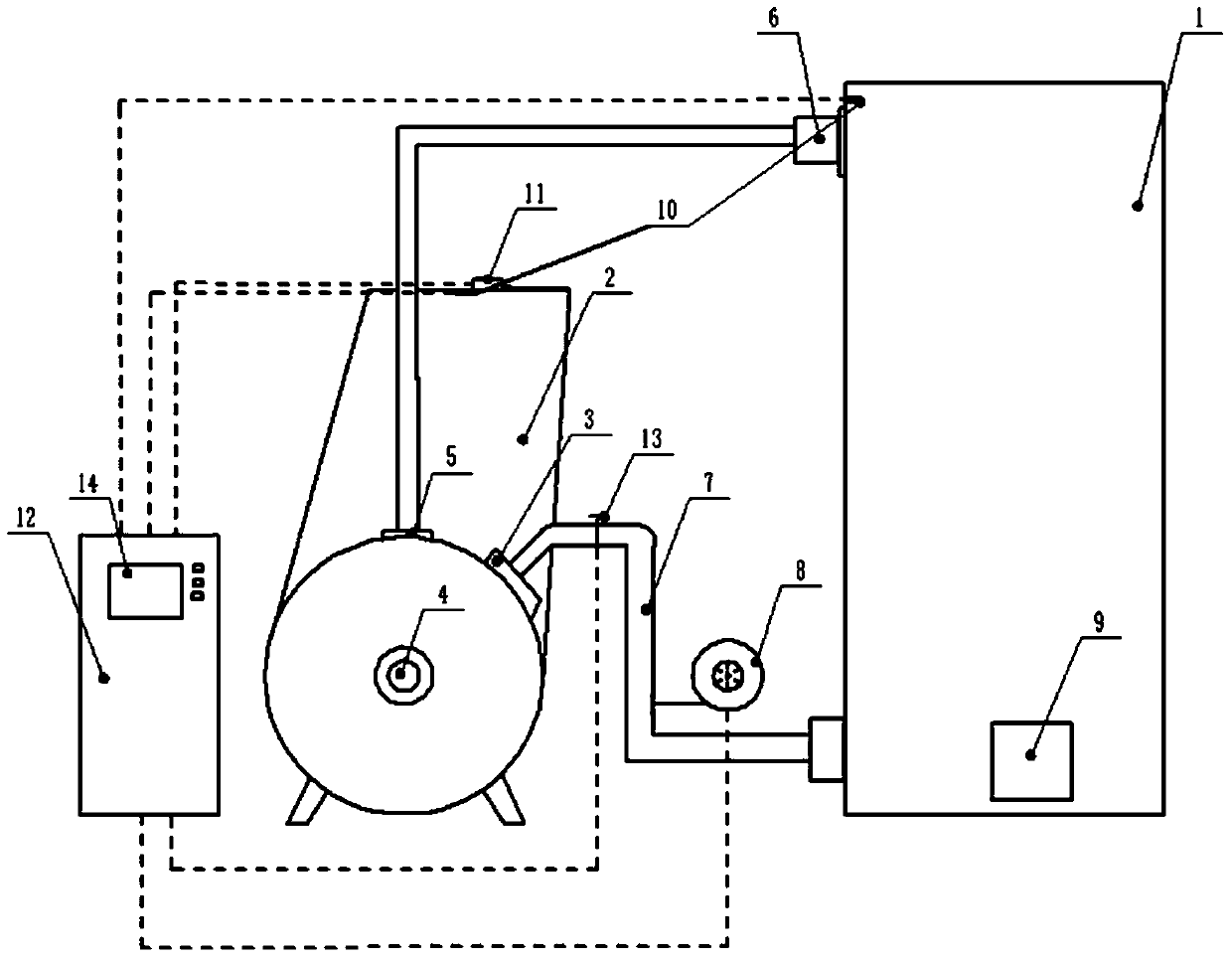

[0027] The described alkali recovery boiler tail gas circulation treatment method and equipment, including: alkali recovery boiler 1, disc evaporator 2, atomizing nozzle 3, papermaking black liquor inlet 4, disc evaporator tail gas inlet 5, alkali recovery boiler exhaust gas Port 6, liquid alkali recovery pipe 7, liquid alkali pump 8, incinerator outlet 9, temperature sensor 10, electromagnetic exhaust valve 11, control cabinet 12, flow control valve 13 and controller 14, the papermaking black liquor inlet 4 and The disc evaporator 2 is fixedly connected, the electromagnetic exhaust valve 11 is located at the top of the disc evaporator 2, one end of the liquid alkali recovery pipe 7 is connected with the bottom of the disc evaporator 2, and the other end is connected with the atomizing nozzle 3 in the disc evaporator 2. Connection, the flow control valve 13 is installed between the liquid alkali recovery pipe 7 and the atomizing nozzle 2, the liquid alkali pump 8 is located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com